Display panel and manufacturing method thereof

A technology for display panels and manufacturing methods, which is applied in the fields of instruments, nonlinear optics, optics, etc., and can solve the problems of increased production costs, large gaps in color-resisting layers, and incompatibility of optical filters, etc.

Pending Publication Date: 2022-07-01

TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the method of matching the white point by adjusting the film thickness of each color resist has certain limitations. For example, after the film thickness of each color resist is determined, its brightness cannot be changed; The method of matching the white point by adjusting the thickness may cause the color-resist layer to be too large, which will affect the display effect

Moreover, a set of filters with a fixed color resistance film thickness must be matched to meet the matching white point of a specification, so that the filters used by liquid crystal display panels with different product specifications do not have commonality, which will increase production costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

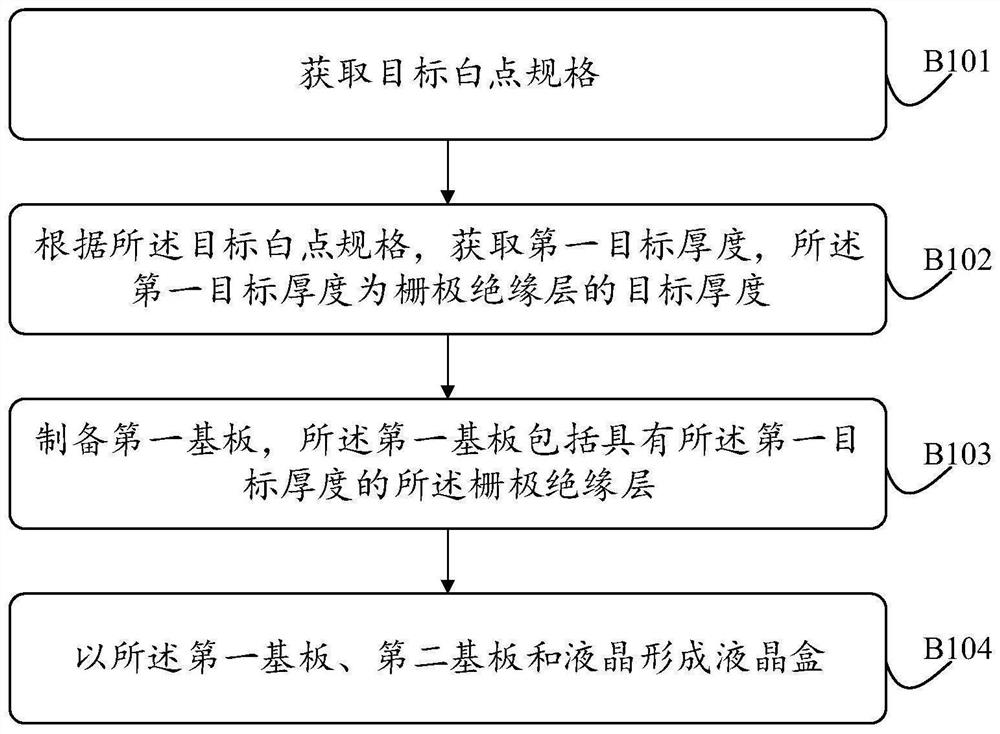

[0096] The manufacturing method of the display panel provided by the embodiment of the present application will be described below by way of a specific embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

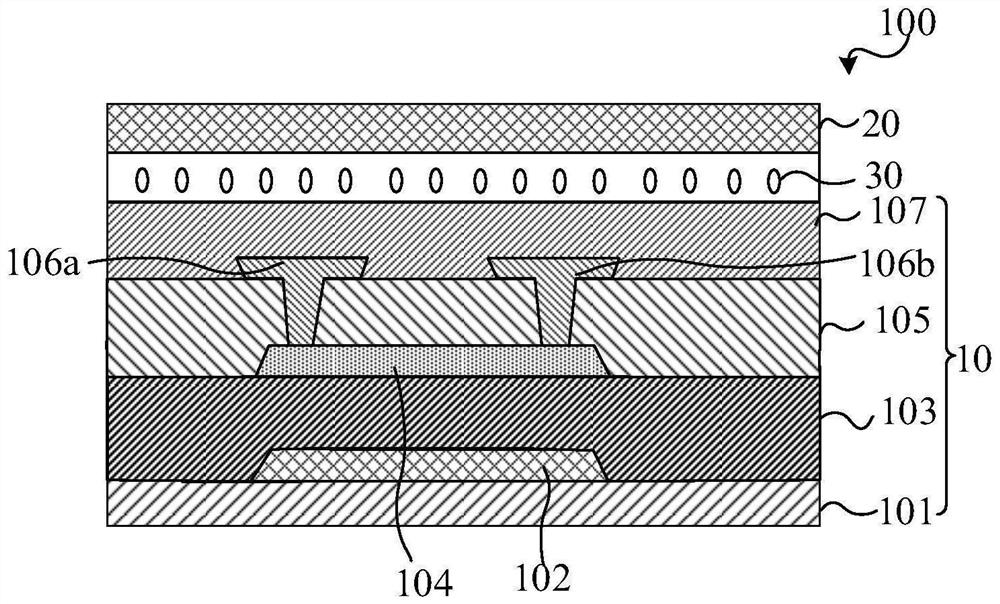

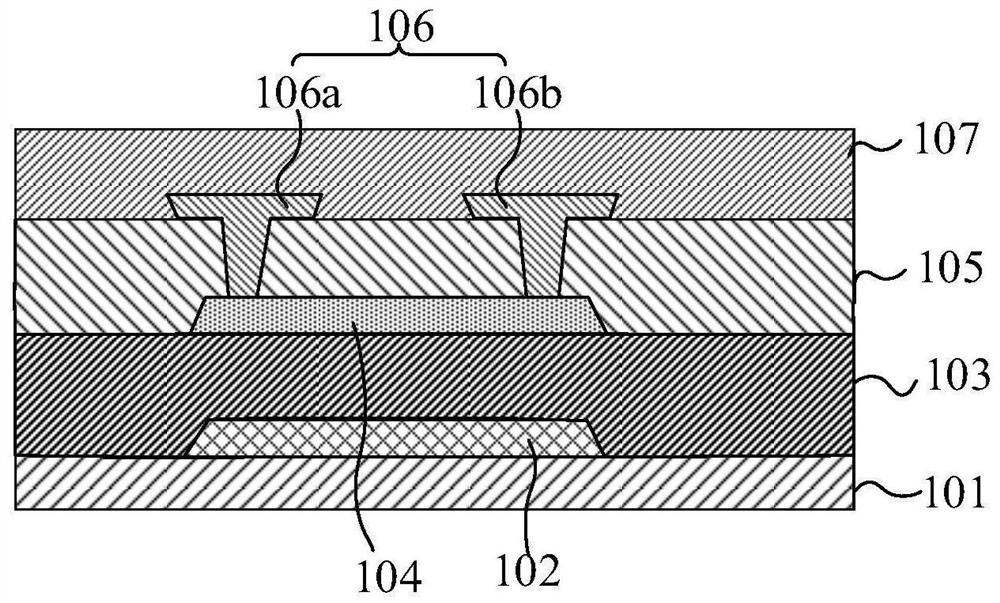

The invention discloses a display panel and a manufacturing method thereof. The manufacturing method of the display panel comprises the steps that the specification of a target white point is obtained; and obtaining a first target thickness according to the target white dot specification, the first target thickness being the target thickness of the gate insulation layer. A first substrate is prepared, the first substrate including a gate insulating layer having a first target thickness. And forming a liquid crystal box by the first substrate, the second substrate and the liquid crystal. According to the manufacturing method of the display panel provided by the invention, the light transmittance of the gate insulating layer can be adjusted by adjusting the thickness of the gate insulating layer, so that the white dot specification of the display panel is adjusted.

Description

technical field [0001] The present application relates to the field of display technology, and in particular, to a display panel and a manufacturing method thereof. Background technique [0002] A liquid crystal display is basically composed of a liquid crystal display panel (Liquid Crystal Panel) and a backlight module (Black Light Module). The light source provided by the backlight module is controlled by the liquid crystal display panel to form an image. The liquid crystal display panel contains color filters, and the light generated by the backlight module is mixed by the color filters to present the desired color. The ideal state is to make the reproduced color as close to the natural color as possible, or, as required Depending on the purpose or the use environment of the LCD device, the requirements for the degree of color reproduction are also different, and the color needs to be adjusted as needed. [0003] Of particular importance is the adjustment of the white po...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02F1/1333G02F1/1368

CPCG02F1/1333G02F1/1368

Inventor 邓枫

Owner TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com