Switching device with reduced partial discharge and improved three-phase point characteristics

A partial discharge and shaft technology, which is applied in the direction of horizontally pulling isolated switchgear, switchgear parts, electric switches, etc., can solve the problems of accelerated aging and breakdown of insulators, achieve optimized shape and positioning, and minimize local The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

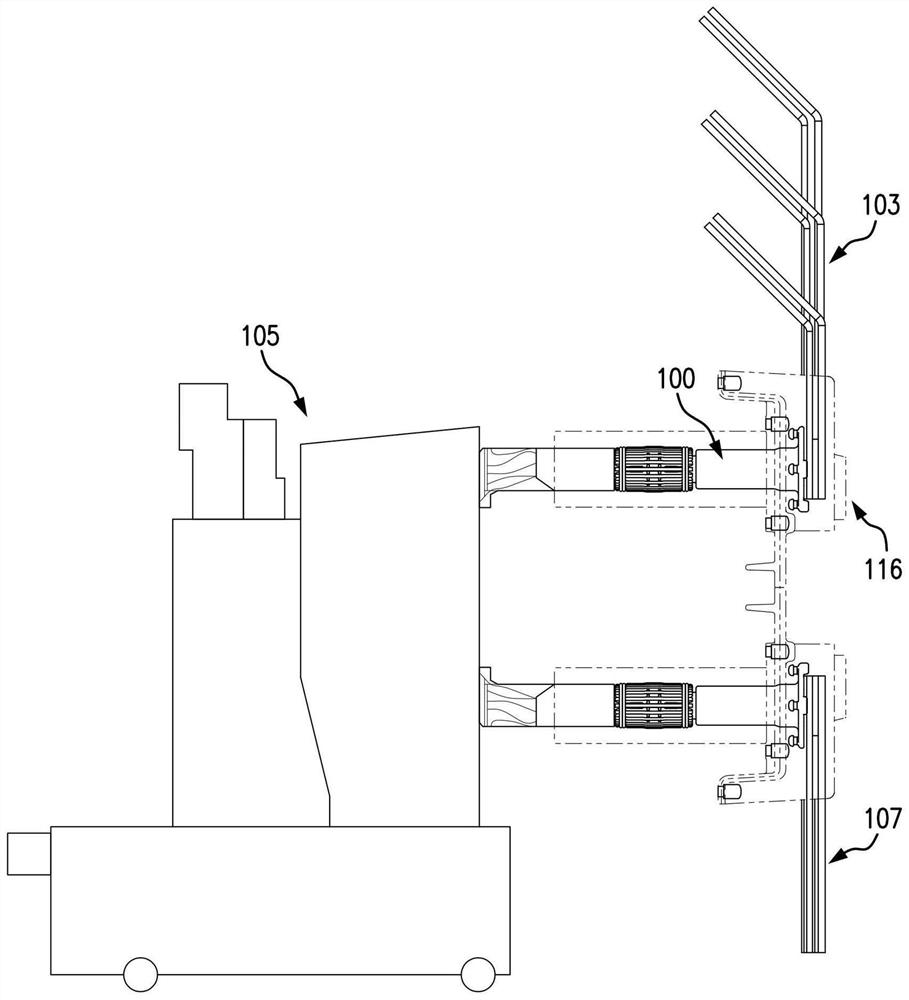

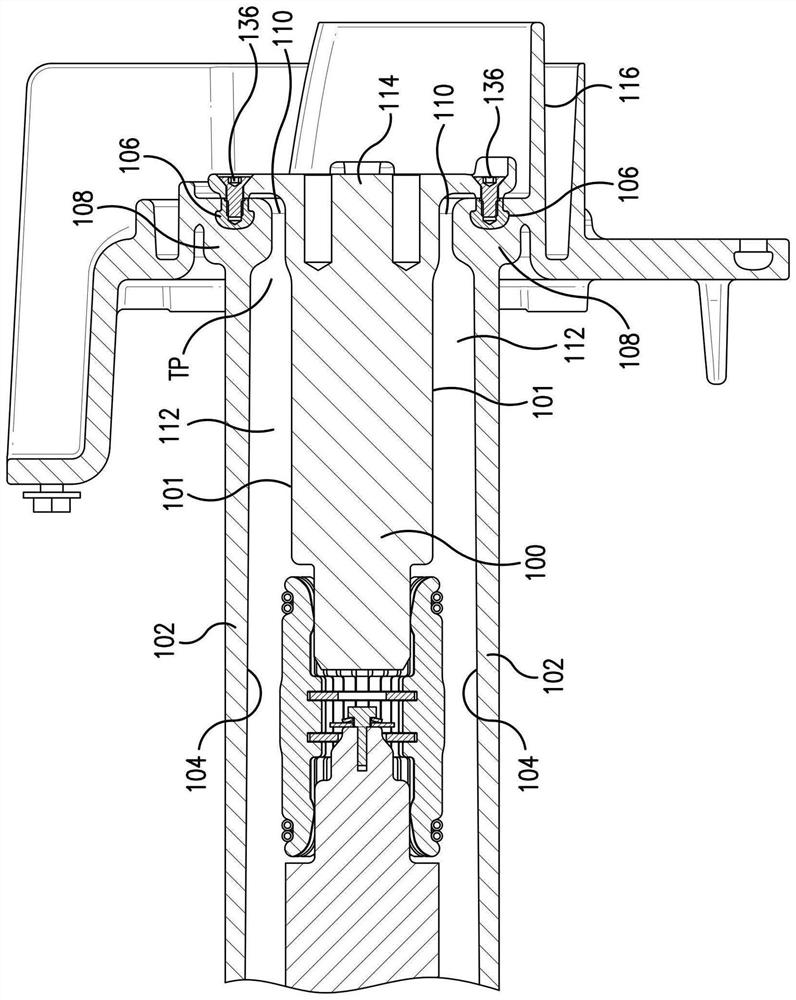

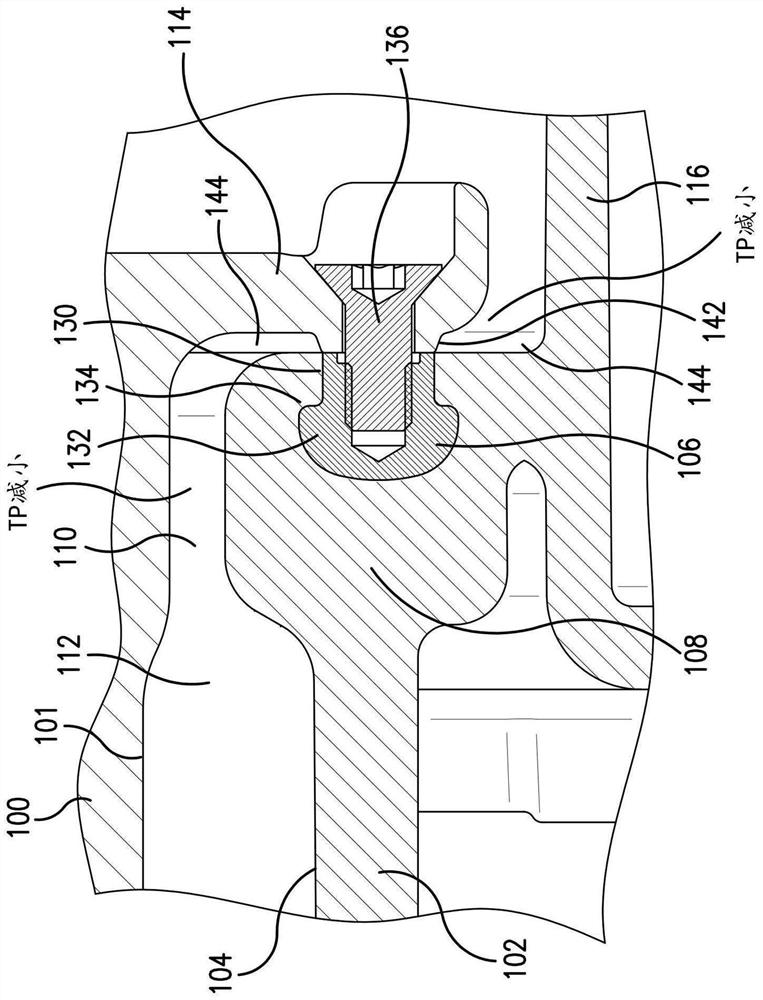

[0036] Figure 1Ais an overall view of a medium voltage circuit breaker 105 with a first primary plug bus 100 connected to the column bus 103 and a second primary plug bus connected to the load bus 107 . The medium voltage circuit breaker may be rated for a maximum voltage of, for example, from 5 to 15 kV, a continuous current rating of, for example, from 1200 to 2000 amperes, and a mains frequency of, for example, 60 Hz. The clusters of fingers are shown electrically connecting the conductors or primary patch bus 100 to the return conductors, which are connected to the main contacts of the circuit breaker. The primary patch bus 100 is a cylindrical conductor that can be connected to the disc plate 114 ( Figure 1B ) cast as a single piece. The puck is electrically connected to the column bus 103 to power the circuit breaker. The annular insulating sleeve 102 and insulating sleeve 116 may be formed as a one-piece insulator that may be Figure 1B ) to the external support st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com