Brush braid type generator large shaft grounding device

A grounding device and generator technology, applied in the direction of connection with the grounding device, etc., can solve the problems of discharge corrosion, burnt bearing seat, poor contact of the grounding carbon brush, etc., and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

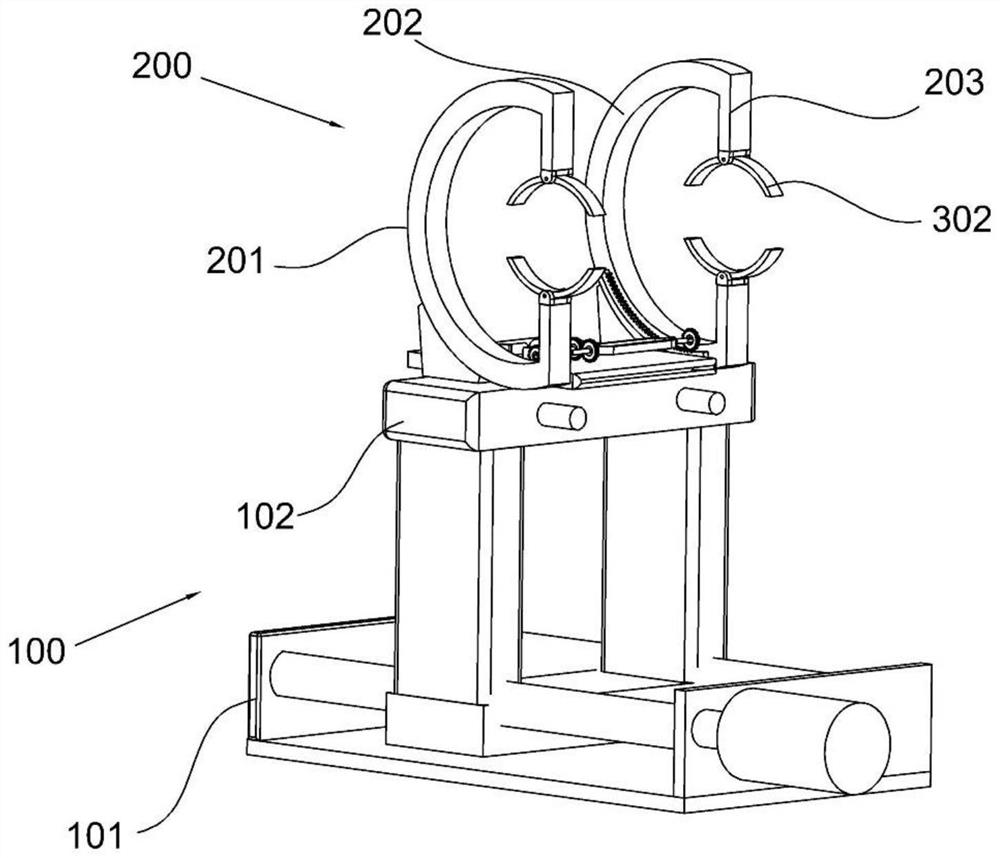

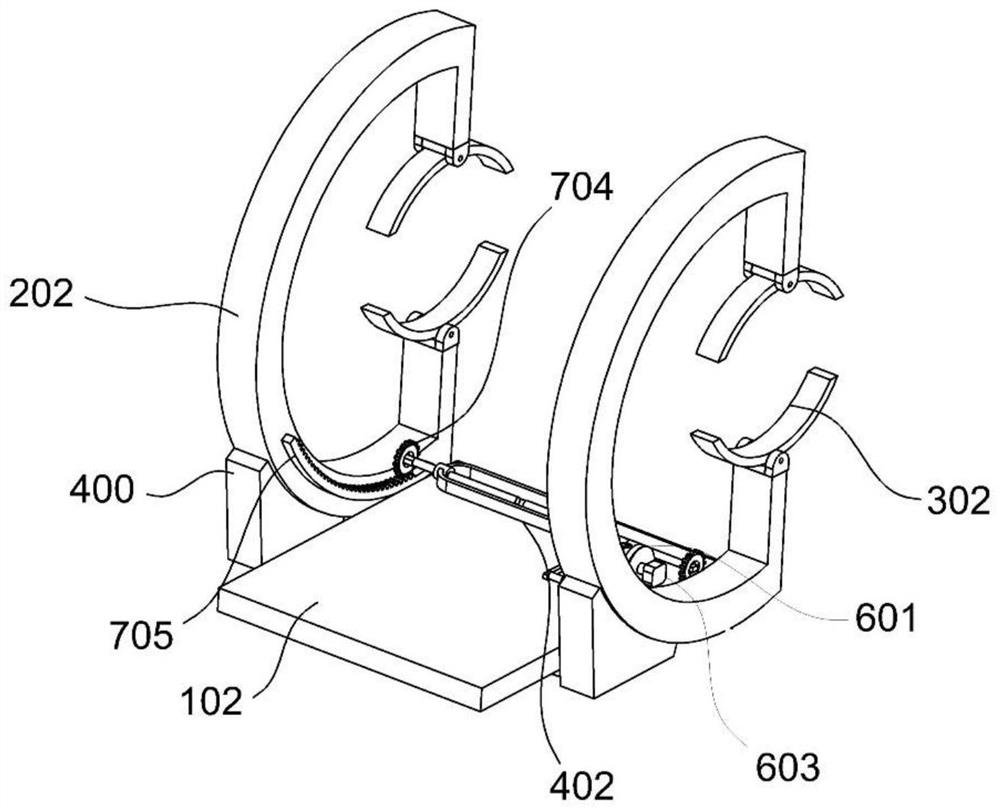

[0031] refer to Figure 1-4 , the present invention discloses a braided generator shaft grounding device, including a bracket assembly 100, in this embodiment, the bracket assembly 100 includes a bottom bracket 101, the bottom bracket 101 is placed horizontally on the ground, and the bottom bracket 101 The upper end bracket 102 is slidably connected with the upper end bracket 102 . The lower end of the upper end bracket 102 is rectangular, and the upper end is folded upward to form a trapezoidal table shape.

[0032] Preferably, in this embodiment, the sliding member includes a lead screw disposed on the bottom bracket 101, the lead screw is horizontally arranged, and a matching hole for matching the lead screw is provided at the lower end of the upper bracket 102, the matching hole and the lead screw Threaded connection, and one end of the lead screw is connected to the motor, at the same time a dovetail block is provided at the lower end of the upper bracket 102, and a dovet...

Embodiment 2

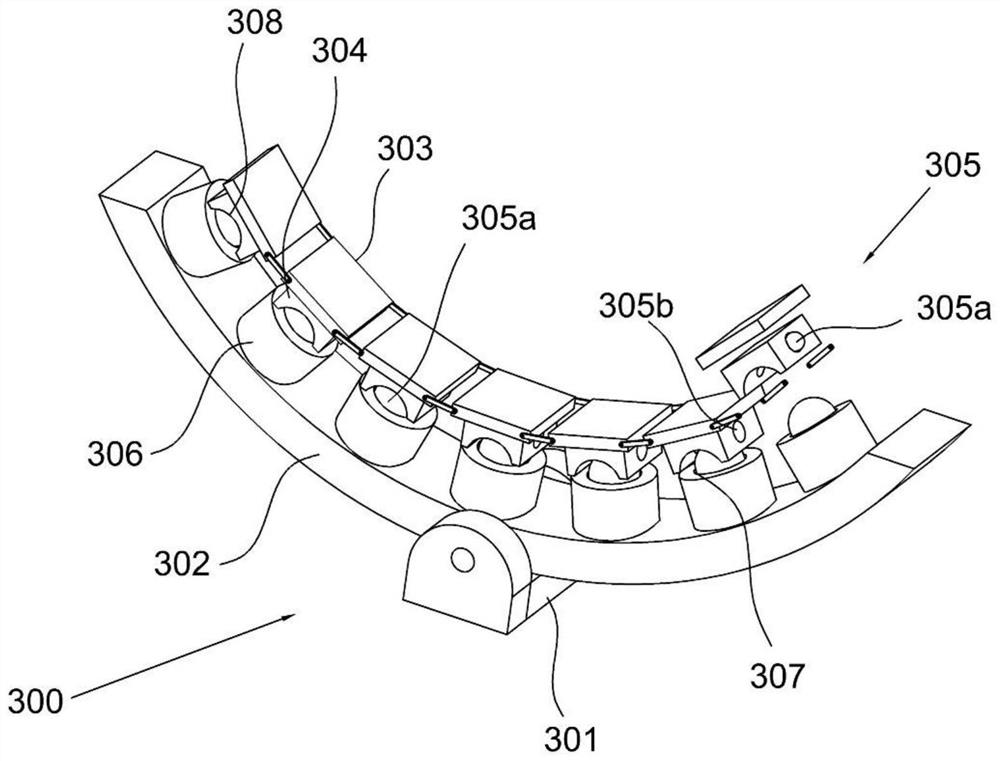

[0038] refer to Figure 3-5 This embodiment is different from the first embodiment in that the sliding member 401 includes an adjusting ring 402 rotatably connected to the arc-shaped plate 400 , threaded holes 403 opened at both ends of the adjusting ring 402 and screwed in the adjusting ring 402 The adjusting rod 404, the end of the adjusting rod 404 is provided with a short rod head 405, the first bending arm 201 and the second bending arm 202 are provided with a short rod slot matched with the short rod head 405, the The adjusting ring 402 is provided with a rotating member 500 , and the rotating member 500 includes a first gear 501 coaxially disposed on the adjusting ring 402 , a second gear 502 meshing with the first gear 501 , and extending from the rotating shaft of the second gear 502 The middle bearing rod 503, the rear end of the middle bearing rod 503 is coaxially provided with a locking wheel 504, wherein the locking wheel 504 is provided with a number of locking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com