Preparation method and preparation device of cleaning agent composition

A technology for preparing devices and compositions, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of complex structure of stirring components, insufficient cleaning, and influence on the next use of mixing tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

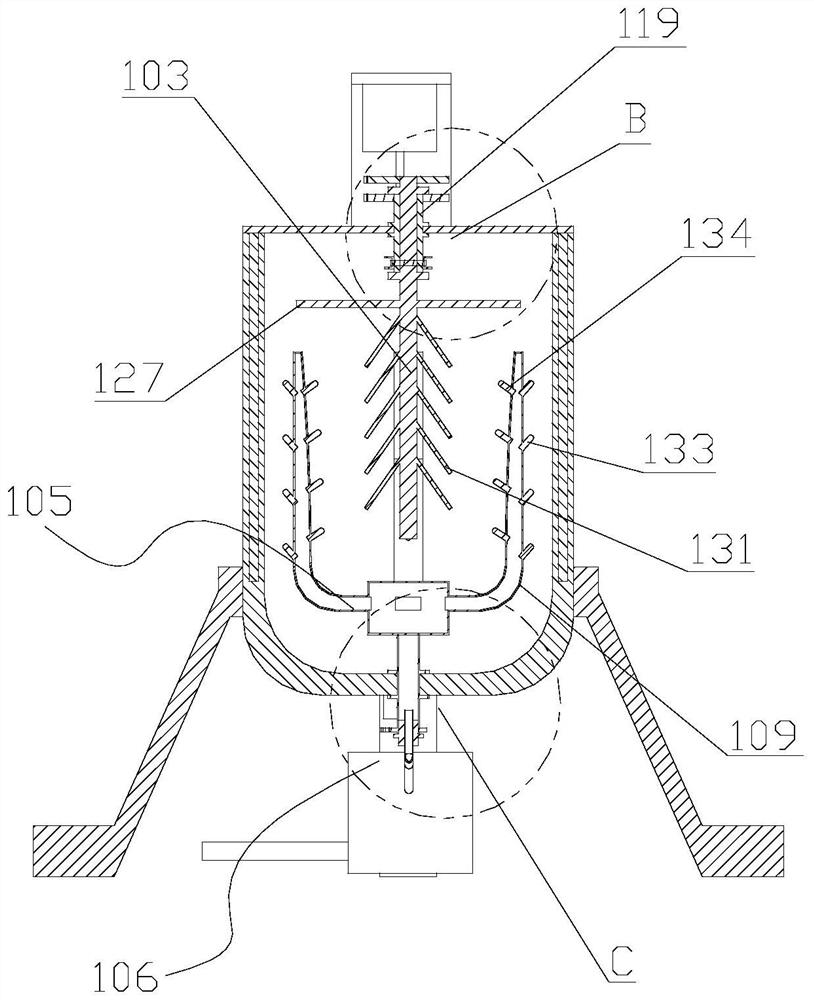

[0050] On the basis of the first embodiment, see Image 6 , Image 6 It is a cross-sectional view of the internal structure of the cleaning agent composition preparation device of the second embodiment. The present invention provides a cleaning agent composition preparation device further comprising an inner side wall scraping off assembly 201, and the inner side wall scraping off assembly 201 includes a mounting member 202 , connecting rod 203 , first scraper 204 and second scraper 205 .

Embodiment approach

[0051] For this specific embodiment, the inner side wall scraping assembly 201 is installed on the rotating disk 127, and the inner side wall scraping assembly 201 is used to scrape off the cleaning agent raw material attached to the inner wall of the mixing tub 101, The inner side wall scraping assembly 201 is provided on the rotating disk 127 , and when the rotating disk 127 rotates, the inner side wall scraping assembly 201 is used to scrape off the cleaning agent adhering to the inner side wall of the mixing tub 101 The raw material of the cleaning agent is prevented from adhering to the inner side wall of the stirring barrel 101, which affects the effect of the prepared cleaning agent composition in the next use.

[0052] The mounting member 202 is detachably connected to the rotating disk 127 , one end of the connecting rod 203 is detached and connected to the mounting member 202 , and the other end of the connecting rod 203 is detached and connected to the first scraper ...

no. 3 example

[0055] On the basis of the first embodiment, see Figure 7 and Figure 8 , Figure 7 It is a front view of the preparation device of the cleaning agent composition of the third embodiment, Figure 8 for Figure 7 A cross-sectional view of the internal structure of the D-D line. The present invention provides an apparatus for preparing a detergent composition further comprising a temperature control unit 301 , and the temperature control unit 301 includes a controller 302 , a temperature sensor 303 and an electric heating wire 304 .

[0056] For this specific embodiment, the temperature control unit 301 is used to control the temperature in the stirring tank, so as to avoid condensation of the detergent raw material in the stirring tank 101 when the temperature is low, thereby reducing the stirring efficiency.

[0057] Wherein, the inner wall of the mixing barrel 101 is provided with an interlayer 305, the interior of the interlayer 305 is provided with the electric heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com