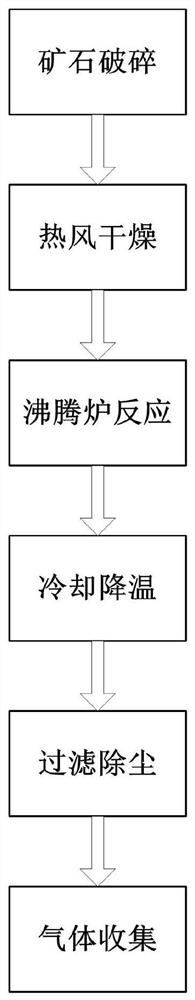

A pretreatment process for the production of industrial concentrated sulfuric acid

A technology of concentrated sulfuric acid and pretreatment, which is applied in the direction of sulfur compounds, separation methods, transportation and packaging, etc. It can solve the problems of impurity collection, incomplete filtration, and inability to remove impurities, so as to improve production efficiency, prolong service life, and benefit The effect of subsequent use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

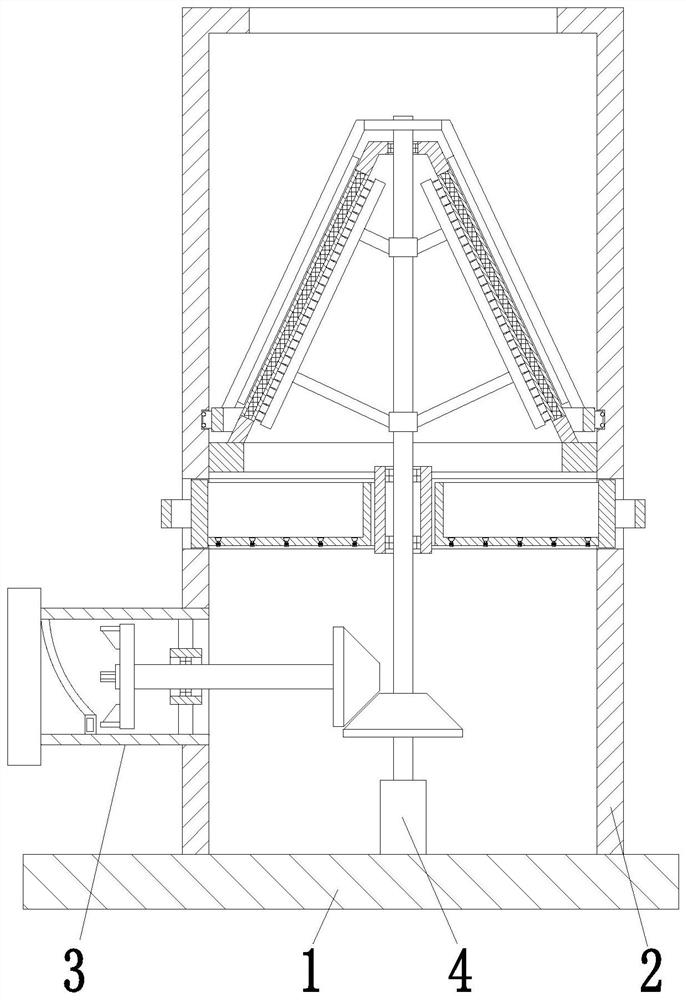

[0036] In conjunction with the following drawings, embodiments of the present invention will be described in detail, but the present invention can be defined by the claims, and many different embodiments of cover.

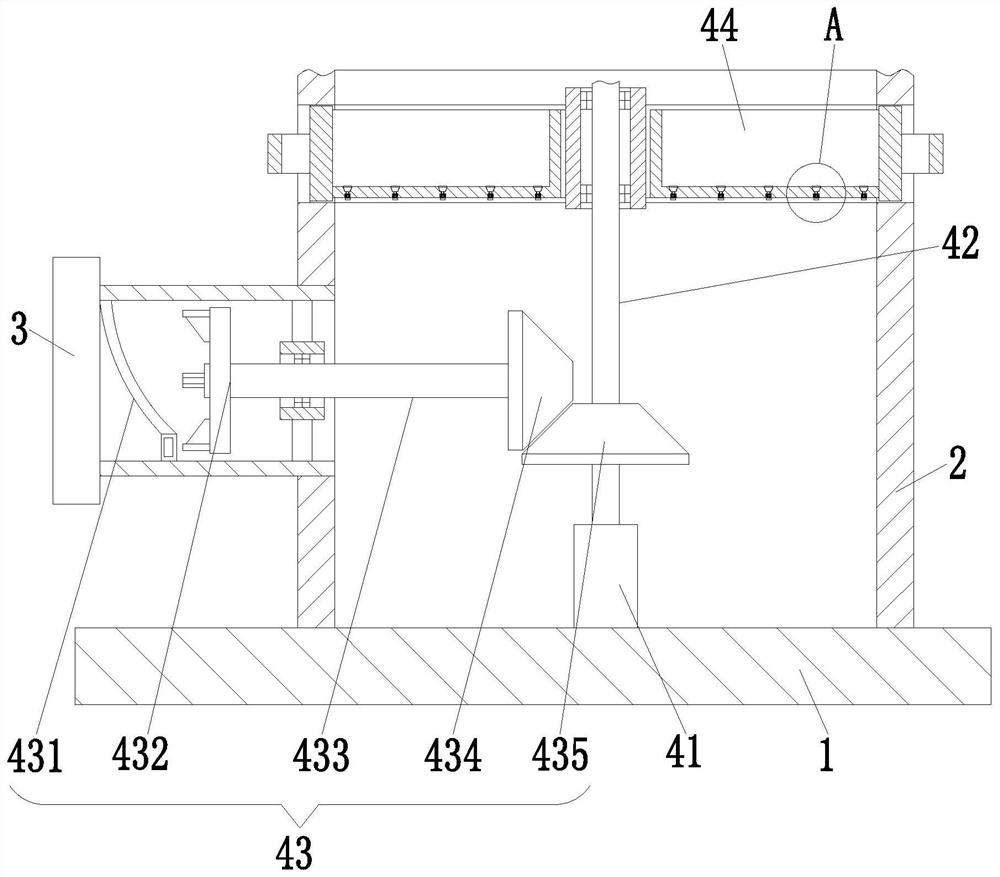

[0037] like Figure 1 to 8 Shown, an industrial preparation of concentrated sulfuric acid pre-treatment process, the industrial preparation of concentrated sulfuric acid pre-treatment process using the following processing equipment, the processing equipment comprises a base plate 1, the case frame 2, an intake pipe 3 and the filtering device 4, the the base plate 1 is attached to the upper end of the case frame 2, a hollow cylindrical housing 2 has a frame structure, a lower end of the case frame 2 mounted on the left side of the intake pipe 3, inner housing 2 is attached to the filter holder means 4.

[0038]The filter device 4 includes a housing 41, a rotating shaft 42, a rotating mechanism 43, a collecting mechanism 44, a filter frame 45, a cleaning mechanism 46, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com