Robust control method for flexible assembly system containing single unreliable resource

A flexible assembly and robust control technology, applied in the direction of adaptive control, comprehensive factory control, general control system, etc., can solve problems such as ineffectiveness and unattainable control objectives, and achieve high permissibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

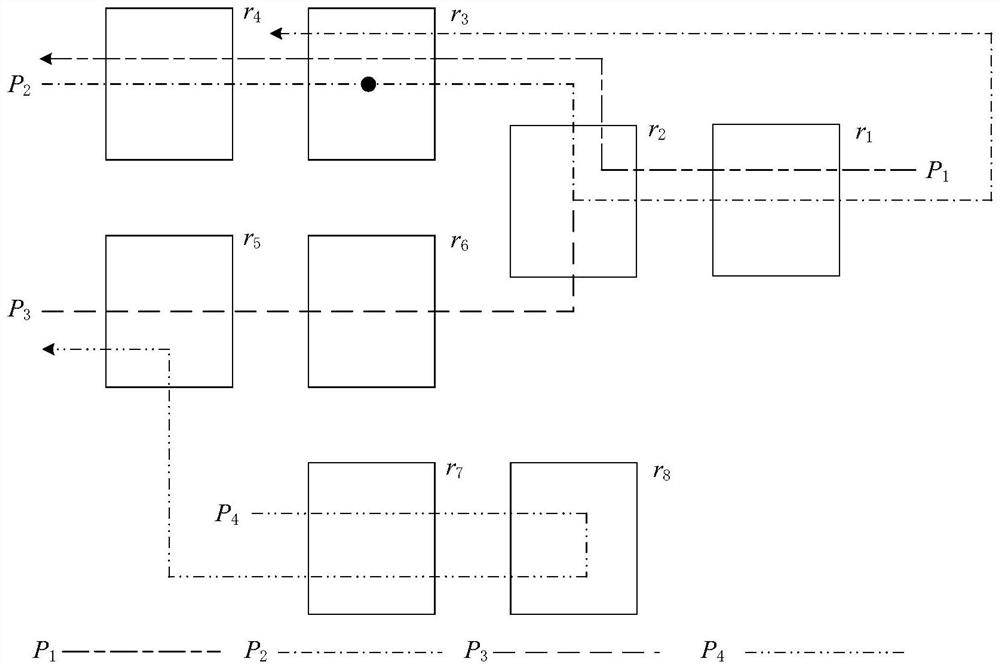

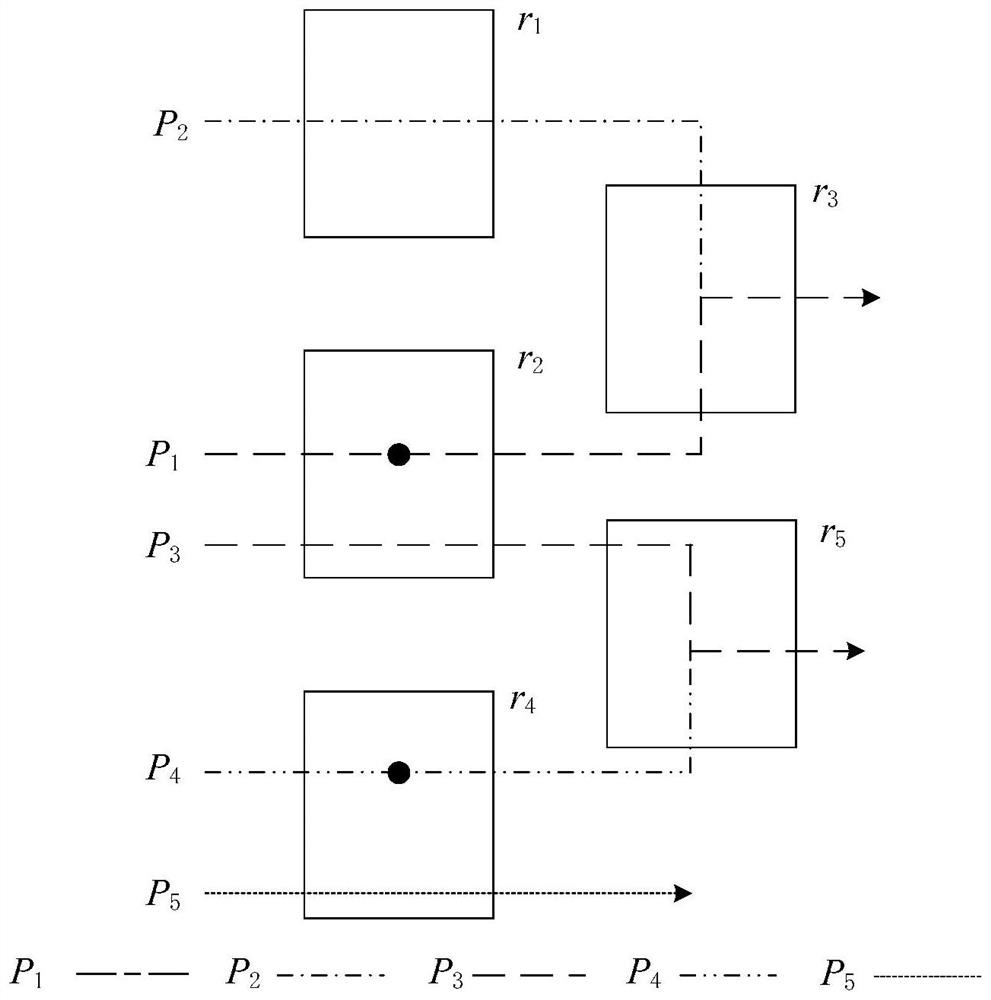

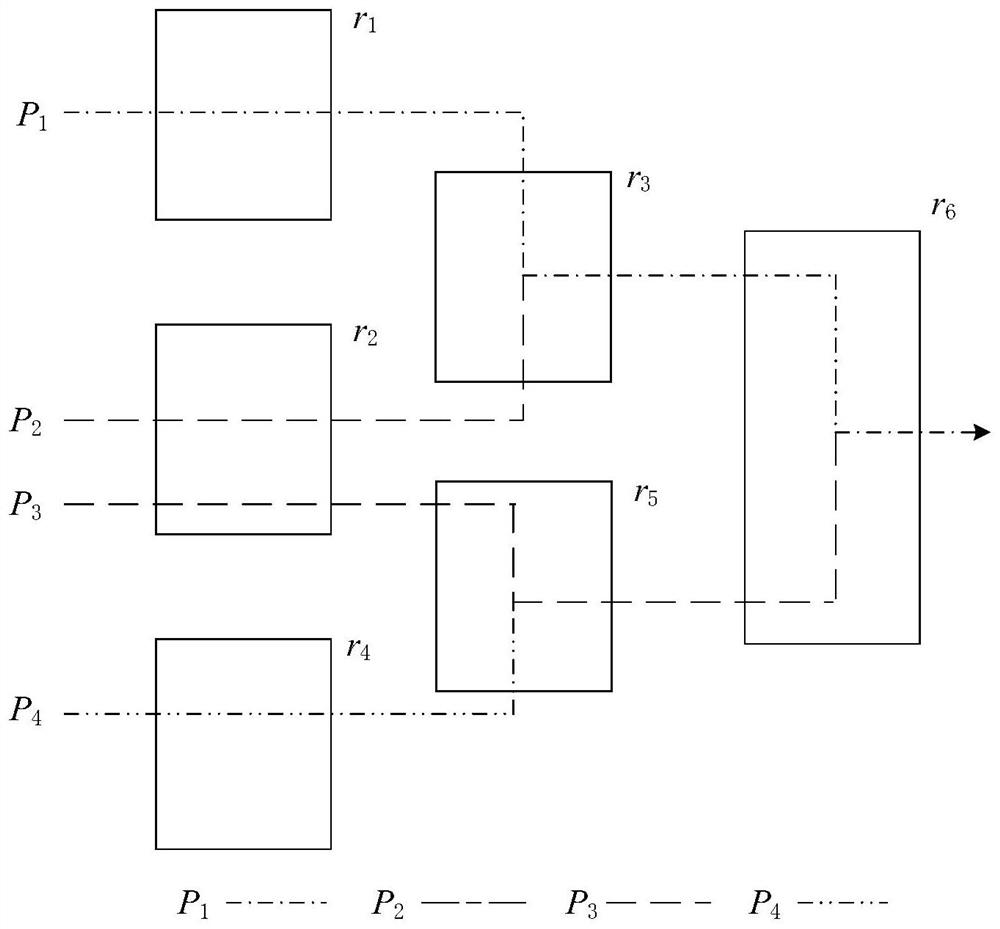

[0279] Example 3: Consider automatic manufacturing system S, suppose R={r 1 ,r 2 ,…,r 6 },P={P 1 ,P 2 ,…,P 4 },l 1 =l 2 =l 3 =l 4 =3. P 1 The operation is P 11 ,P 12 ,P 13 , P 2 The operation is P 21 ,P 22 (P 12 ), P 23 (P 13 ), P 3 The operation is P 31 , P 32 ,P 33 (P 13 ), P 4 The operation is P 41 ,P 42 (P 32 ), P 43 (P 13 ). ρ(P 11 )=r 1 ,ρ(P 12 )=r 3 ,ρ(P 13 )=r 6 ,ρ(P 21 ) = r 2 ,ρ(P 31 )=r 2 ,ρ(P 32 )=r 5 ,ρ(P 41 )=r 4 .ψ 1 =ψ 2 =ψ 3 =ψ 4 =ψ 5 =ψ 6 =4. Suppose r 6 is an unreliable resource. An overview of the system is shown in image 3 . P a ={P 12 ,P 32 ,P 13 }. P a (P 1e )=θ(P 1e )∩P a ={P 11 ,P 12 ,P 13 }∩P a ={P 12 ,P 13 }. because P 12 ∈P a1 (P 1e ). Because θ(P 13 )∩P a ={P 11 ,P 12 }∩{P 12 ,P 32 ,P 13 }=P 12 , Therefore, P a1 (P 1e )={P 12 }. because, P a2 (P 1e )={P 13 }. because So P 32 ∈P a1 (P 3e ). because So P a1 (P 3e )={P 32 }. Similarly, we c...

example 4

[0281] Example 4: Consider image 3 Automatic manufacturing system in . Suppose the current state of the system is q=1+x 11 +x 12 +x 31 , D 1 ={P 11 ,P 12 ,P 31 },D 2 ={1,1,1},D 3 ={P 13 ,P 13 ,P 13 }. Initially, Φ[1]=Φ[2]=Φ[3]=Φ[4]=0;

[0282] given P 12 ∈P a1 ,Π(P 12 )={P 11 ,P 21 },D 1 [1]=P 11 ∈Π(P 12 ), let z=max{q(x 11 )+q(y 11 ), q(x 21 )+q(y 21 )}=1. Then, Φ[1]=0+1-1=0, Φ[2]=0+1-0=1. set q(x 21 )=1, get q=1+x 11 +x 12 +x 21 +x 31 . Assembly at stage P 11 and P 21 the workpiece 1 time, get q=1+2x 12 +x 31 . Since there is no artifact at stage P 32 , so the assembly is obtained at stage P 12 The workpiece on cannot be moved to P 13 superior. because P 12 ∈γ 12 and P 12 ∈Π a , the assembly obtained at stage P 12 The workpiece on it has not been moved temporarily. Let D 1 [1]=P 12 ;

[0283] given P 32 ∈P a1 ,Π(P 32 )={P 31 ,P 41 },D 1 [3]=P 31 ∈Π(P 32 )}, let z=max{q(x 31 )+q(y 31 ),q(x 41 )+q(y 41 )}=1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com