Rhino.Inside.Revit-based light steel keel partition wall parametric modeling method and system

A parametric modeling, light steel keel technology, applied in design optimization/simulation, geometric CAD, etc., can solve the problems of model lag and slow speed, and achieve the effect of reducing the running capacity and speeding up the running processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

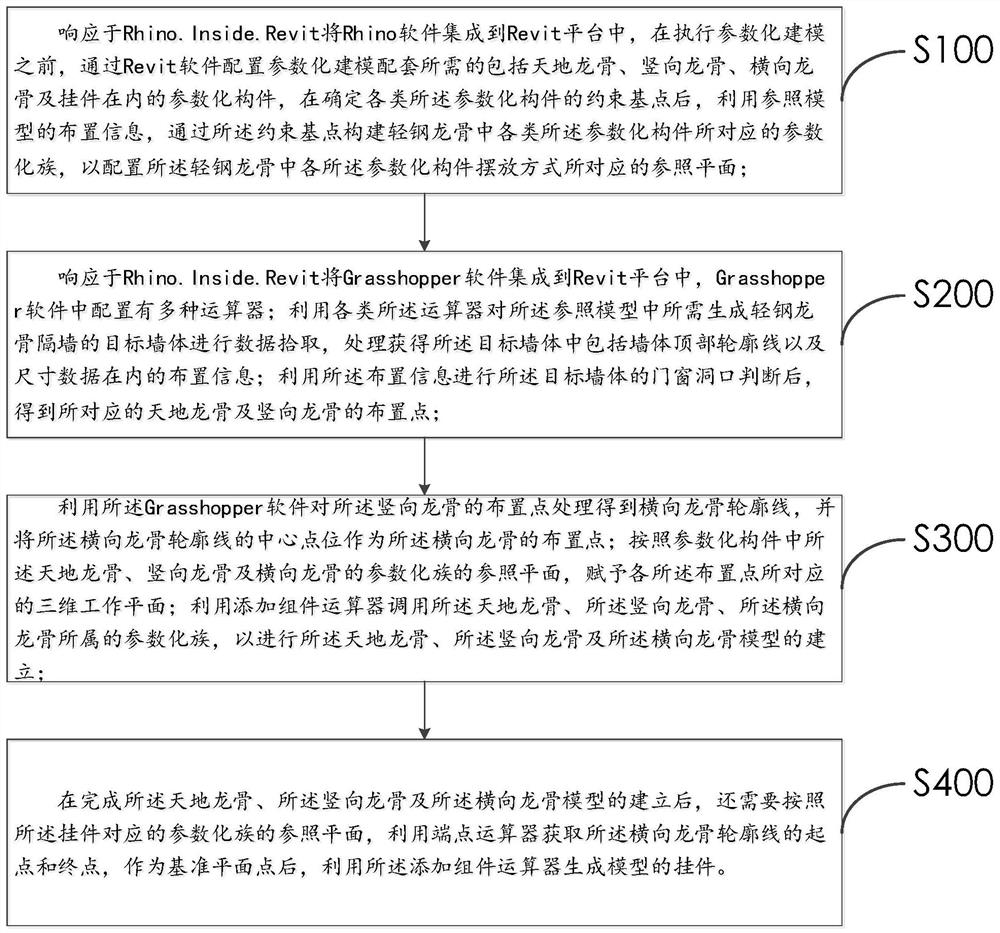

[0038] Reference attached Figure 1-8 As shown, an embodiment of the present application provides a parametric modeling method for a light steel keel partition based on Rhino.Inside.Revit, which includes the following steps.

[0039] In step S100, in response to Rhino.Inside.Revit, the Rhino software is integrated into the Revit platform, and before the parametric modeling is performed, the parametric modeling kit is configured through the Revit software, including the heaven and earth keel, vertical keel, horizontal keel and For parametric components including pendants, after determining the constraint base points of various parametric components, use the layout information of the reference model to construct parametric families corresponding to various parametric components in the light steel keel through the constraint base points to configure the light steel keel. The reference plane corresponding to the arrangement of each parametric component in the steel keel.

[0040]...

Embodiment 2

[0061] The embodiment of the present application provides a parametric modeling system for light steel keel partition walls based on Rhino.Inside.Revit, and adopts the method described in any one of the first embodiment.

[0062] It is further added that the embodiment of the present application also provides a parametric modeling device for light steel keel partition based on Rhino.Inside.Revit, which is configured with a parametric modeling system for light steel keel partition based on Rhino.Inside.Revit . Correspondingly, an embodiment of the present application further provides an electronic device, including: one or more processors, where the processors are configured to store one or more programs, when the one or more programs are processed by the one or more programs When executed by multiple processors, the one or more processors are caused to implement the method described in any one of Embodiment 1. An embodiment of the present application further provides a comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com