Wood-plastic door plate micro-foaming forming and filling equipment and method

A filling equipment and micro-foaming technology, which is applied in the field of wood-plastic door panel production equipment, can solve problems such as unfavorable integrated wood-plastic door panel production work, inconvenience in systematic equipment control, inconvenience in pressing and high-efficiency foam molding work, etc. The effect of pressing high-efficiency foam molding work, convenient transmission work, and easy control work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

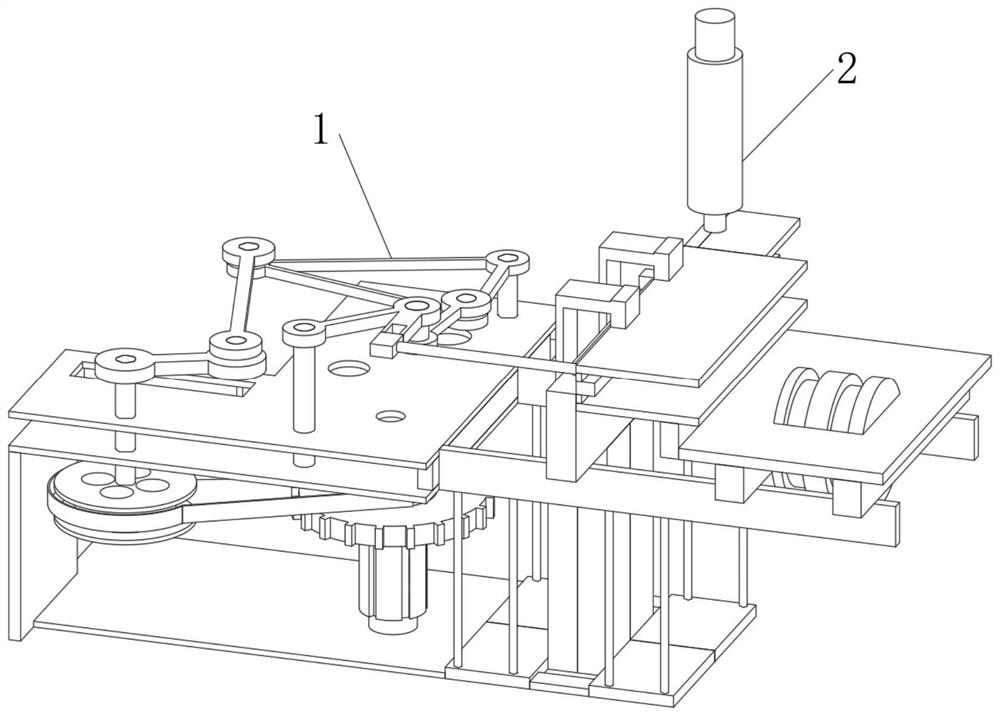

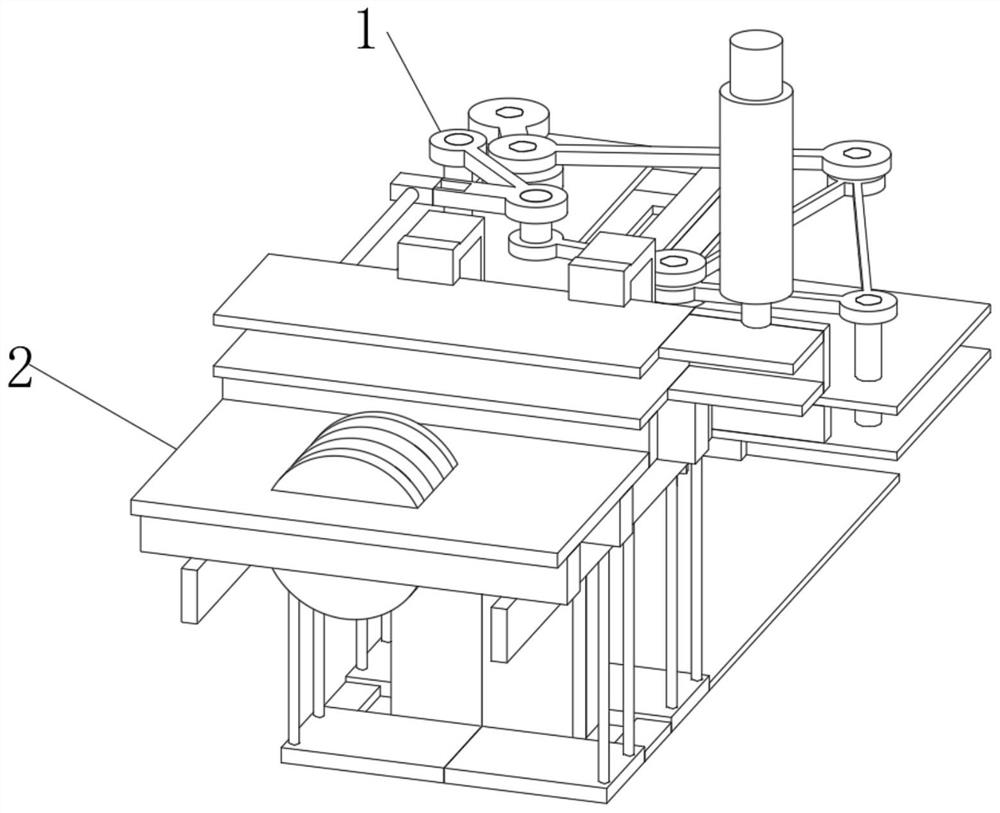

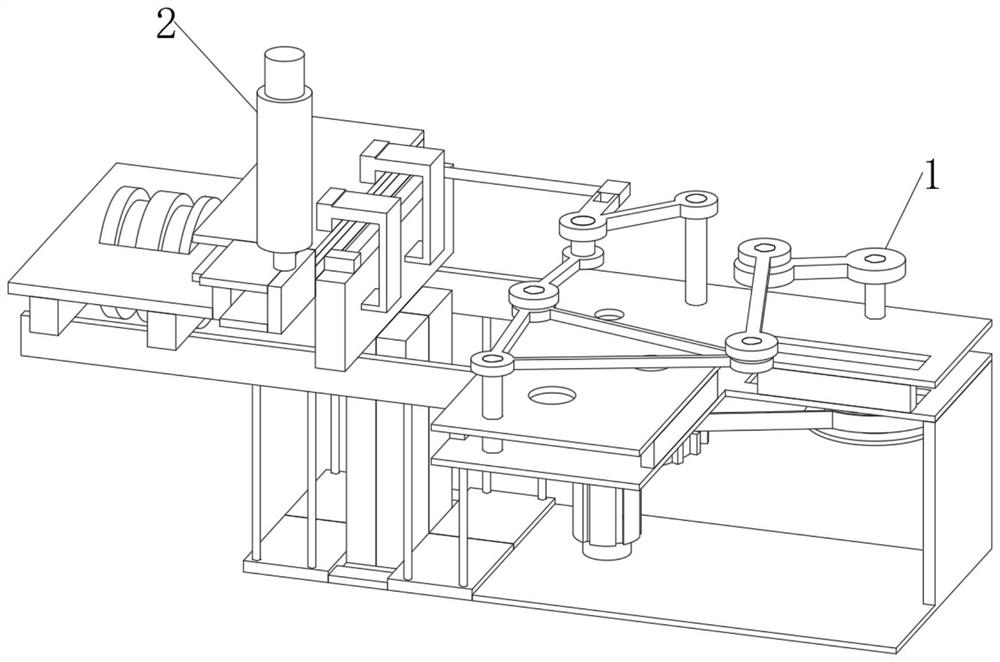

[0042] see figure 1 , figure 2 , image 3 , an embodiment provided by the present invention: a wood-plastic door panel micro-foaming molding and filling equipment, including a pressing derivation structure 1 and a contact production structure 2, and the side end position of the pressing derivation structure 1 is connected with the contact production structure 2. , through the setting of the structure, it is convenient to carry out the combined connection work;

[0043] see Figure 4 , the pressing derivation structure 1 includes a connecting tripod 3, a first cross bar 4, a second cross bar 5, a first mounting pad 6, a second mounting pad 7, a connecting plate 8, a conductive connection guide belt 9, a motor 10, The third crossbar 11 and the fourth crossbar 12;

[0044] The motor 10 is arranged at the bottom position of the inner end of the pressing derivation structure 1. The upper end position of the motor 10 is connected and rotatably connected with the connecting plat...

Embodiment 2

[0051] On the basis of Example 1, as Figure 8 As shown, a communication grooved pipe 22 is fixedly connected to the top of the side end contacting the production structure 2 , and a ventilation grooved pipe 23 is communicated with the upper end of the communication grooved pipe 22 .

[0052] During the implementation of this embodiment, the user installs the communication grooved pipe 22 and the ventilation grooved pipe 23, and the communication grooved pipe 22 and the ventilation grooved pipe 23 are arranged at the top position of the inner end of the contacting production structure 2, and are connected to the connecting groove frame 16, The upper end of the communication groove rod 17 is communicated, which can conduct the guide and exhaust work of the central gas, realize the air purification work, help the unified collection of harmful gases, and better carry out safe production work.

[0053] A method for using a wood-plastic door panel micro-foaming molding and filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com