High-precision timing method and device, and photovoltaic power grid inverter control method and device

A timing device, high-precision technology, applied in photovoltaic power grid inverter control method and device, high-precision timing method, timing, device field, can solve the problem of affecting timing accuracy, long timing time, and MCU timer timing cycle being broken Break and other problems, to achieve the effect of long-term high-precision timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the accompanying drawings and specific embodiments are only exemplary, and should not be construed as any limitation to the protection scope of the present invention.

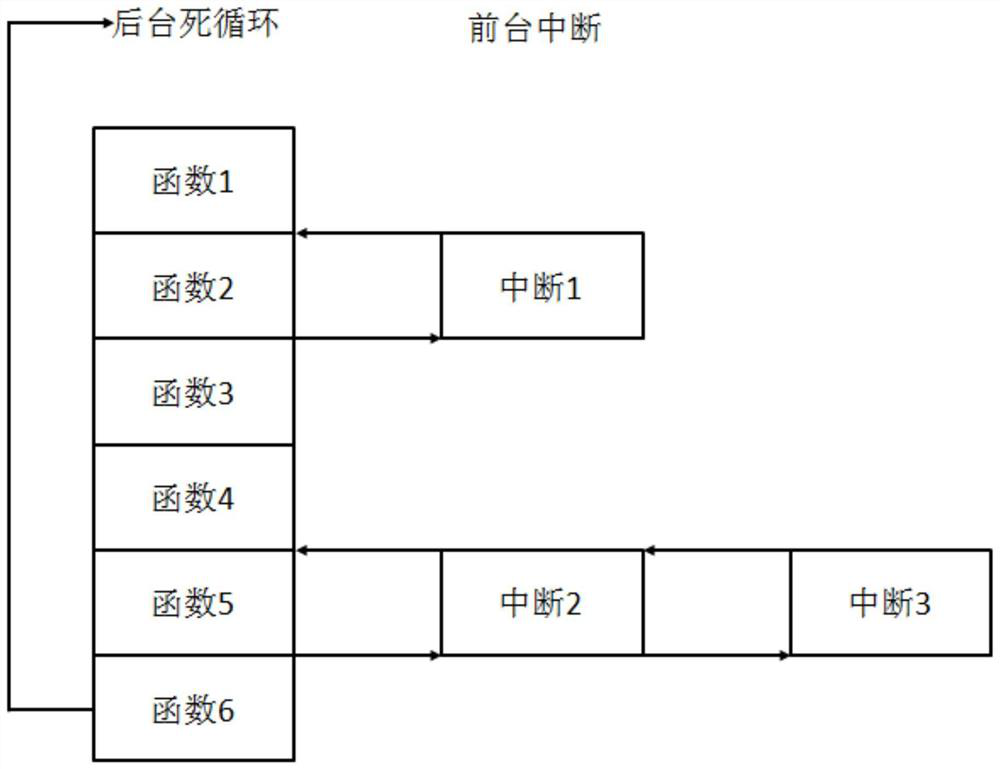

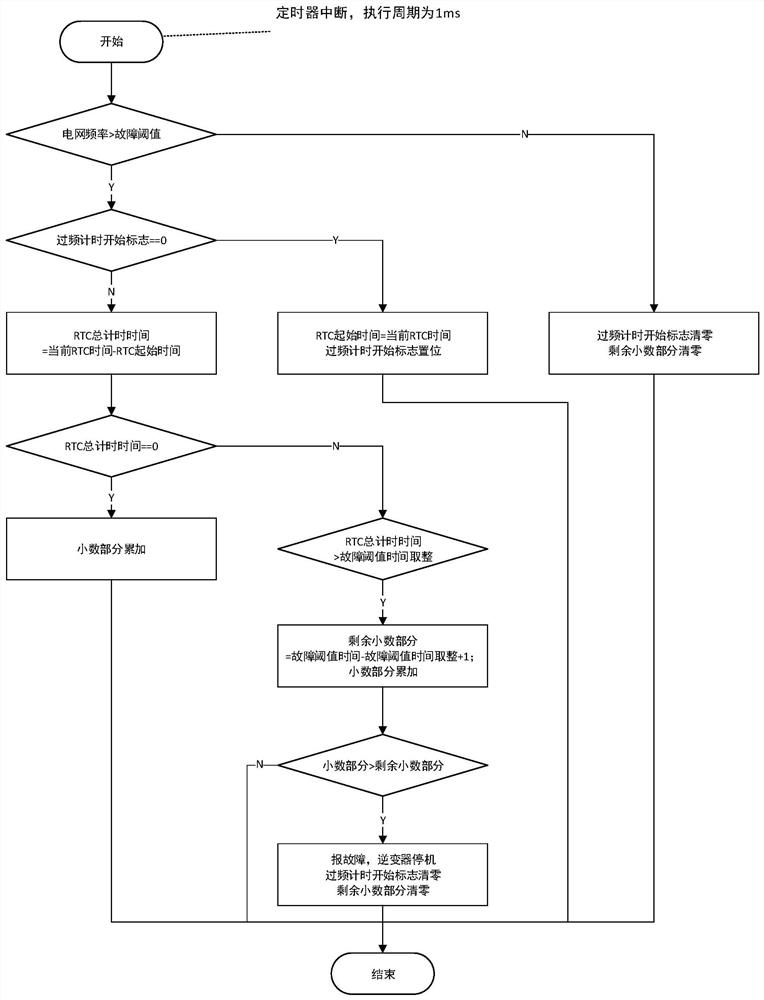

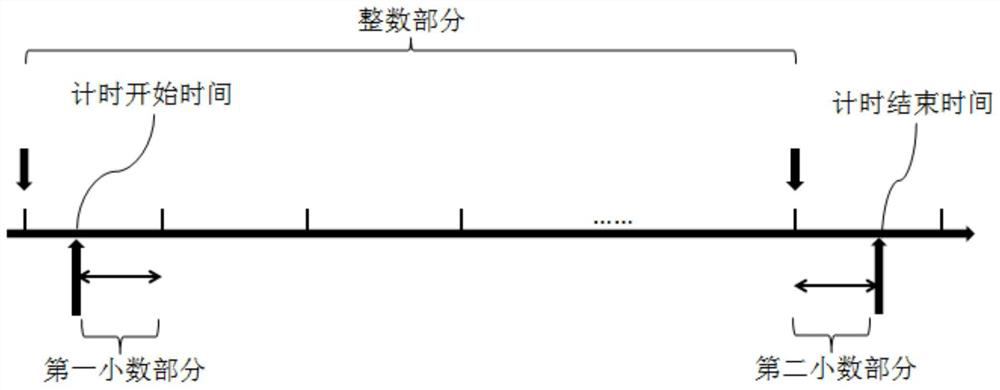

[0048] After the existing master MCU timer is configured with the counting mode, the value of this register will automatically increase by 1 every time a machine cycle passes. When the count value is accumulated to the period value in the set period register, an interrupt request can be generated at the same time. At this time, the counter is cleared, and a fixed-cycle timing interrupt is realized by this method. There are many interrupts in embedded systems, and there are also nested interrupts, such as figure 1 shown.

[0049] At the same time, in the front and back systems, each stage of a control flow is processed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com