Plasma jet coupling modular stealth structure

A plasma and coupling module technology, applied to antennas, electrical components, etc., can solve the problems of large target area, irregular shape of surface area, and inability to maintain uniform plasma all the time, and achieve the effect of reducing cost and resource consumption, and being easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

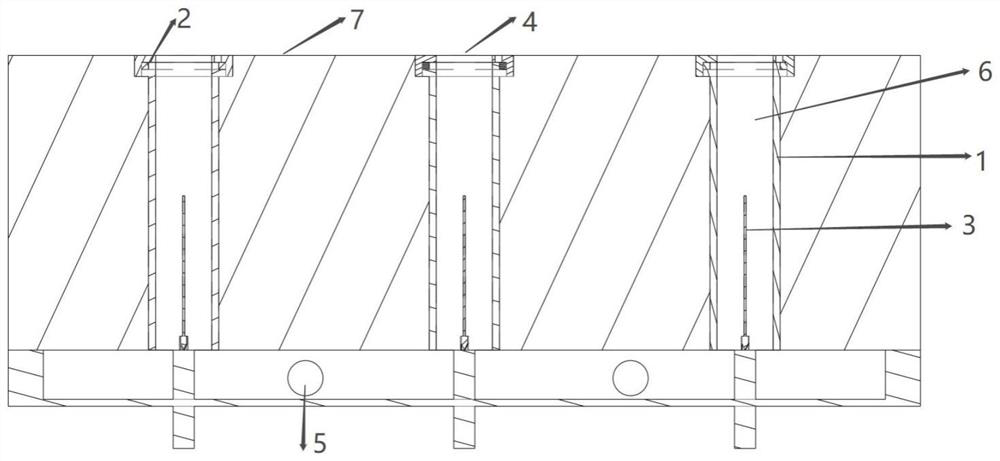

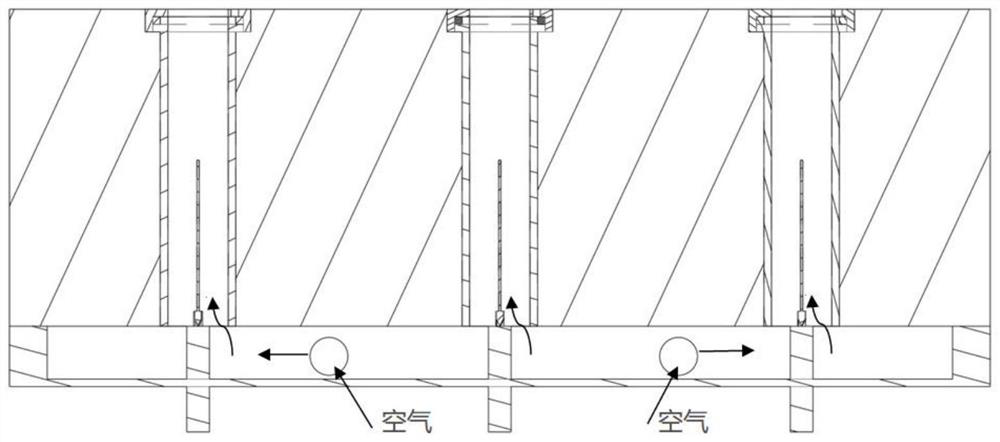

[0039] like Figure 1-7As shown, when the above-mentioned plasma stealth module is realized by the structure a with good fixing effect, it includes a module body, and a plurality of micro-holes are processed in the module body. The inner wall of the micro-hole is an insulating medium layer, and each micro-hole is The top is connected with a negative electrode, the needle-shaped electrode of the positive electrode protrudes into the lower part of the micro-hole, the fixing seat of the needle-shaped electrode passes through the fixing hole at the bottom of the module body, and a spray port is opened on the top of the module body, and the spray port is located above the corresponding negative electrode .

[0040] In order to reduce the resistance of the air and make the air better enter the ionization space in the micropore, the bottom side of the needle-shaped electrode is a pointed structure, which is clamped with the gap of the fixing seat.

[0041] Preferably, the negative e...

Embodiment 2

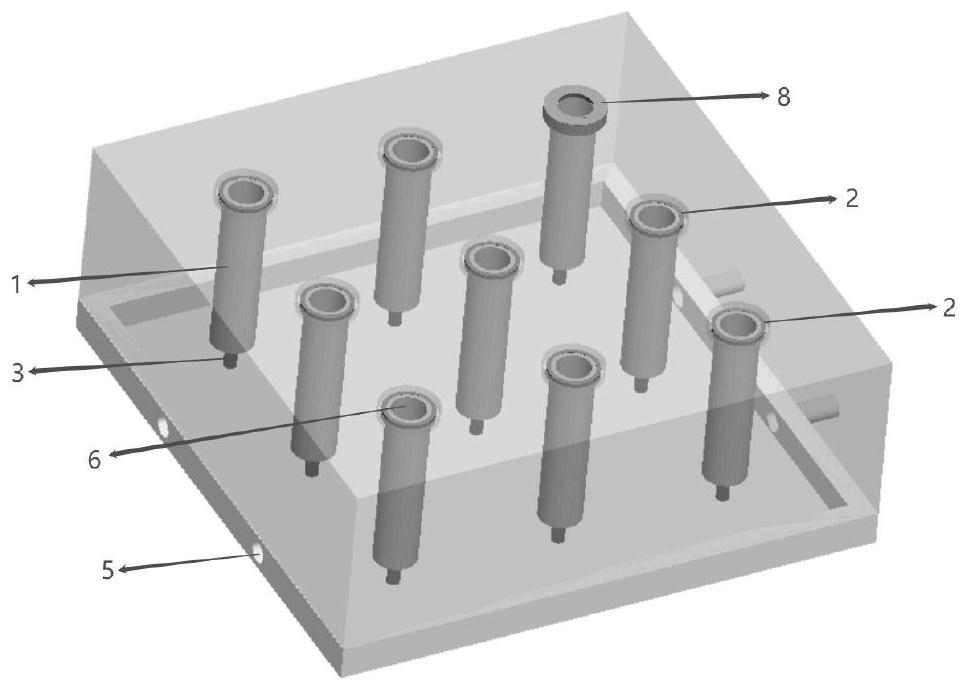

[0045] like Figure 8-13 As shown, when the above-mentioned plasma stealth module is realized by a simple installation structure b, it includes a module body, a plurality of micro-holes are processed in the module body, and a negative plate and an insulating medium layer are sequentially laid on the module body. The negative plate is provided with a through hole at the position of each micro-hole, the top of the through-hole is an injection port arranged on the insulating medium layer, and a needle-shaped electrode is arranged in the lower part of the micro-hole, and the needle-shaped electrode is fixed to the bottom frame connected.

[0046] One side of the negative plate is provided with a negative extension tube, which is inserted into the interior of the adjacent plasma stealth module and is in contact with the negative plate of the module; one side of the fixing frame is provided with a positive extension tube, which is inserted into the phase. It is adjacent to the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com