Device for producing fireproof coating for indoor non-expansive steel structure

A fire-resistant coating, non-expanding technology, applied in the direction of measuring devices, analysis materials, transportation and packaging, etc., can solve the problems of low production efficiency, non-intelligent, increased labor costs, etc., to reduce labor costs, improve production efficiency, Effect of fast process changeover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

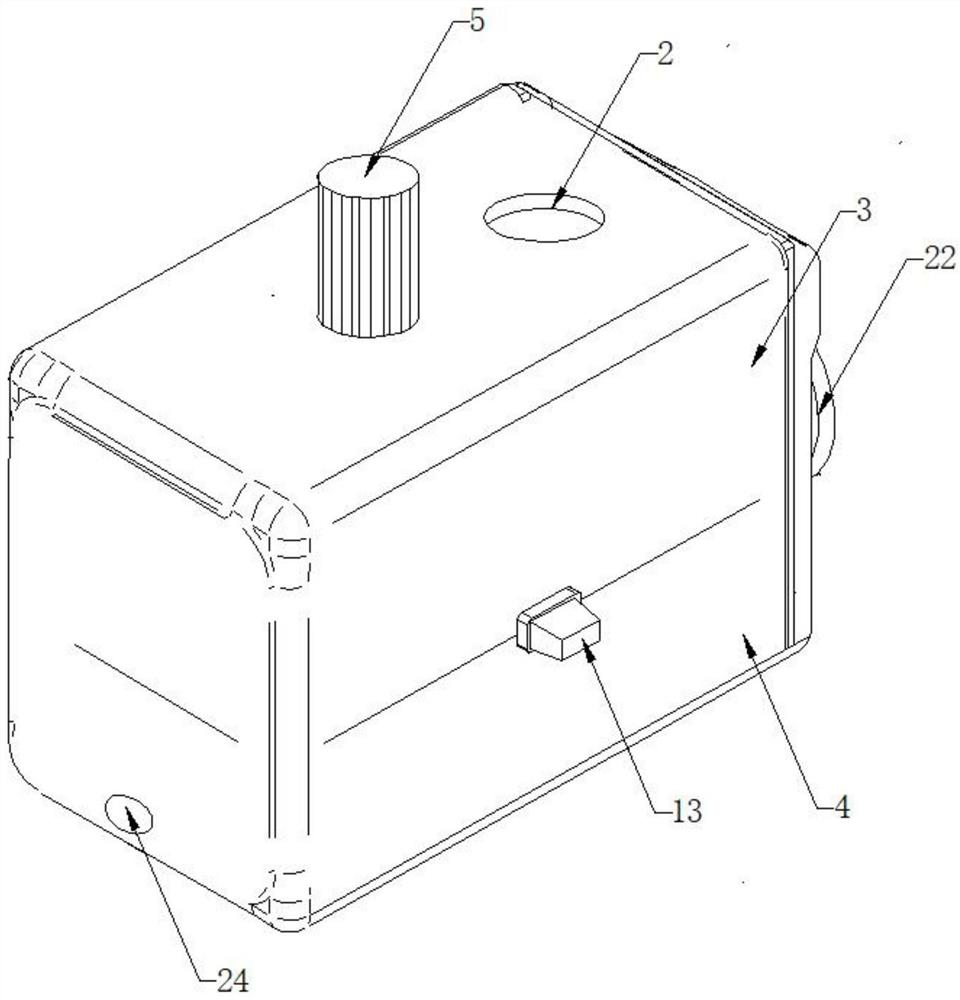

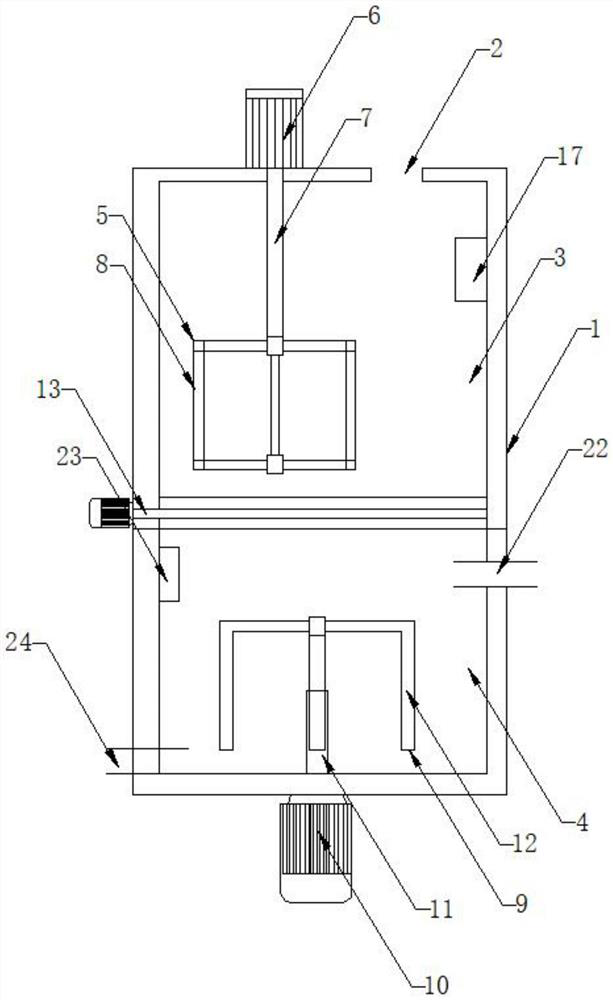

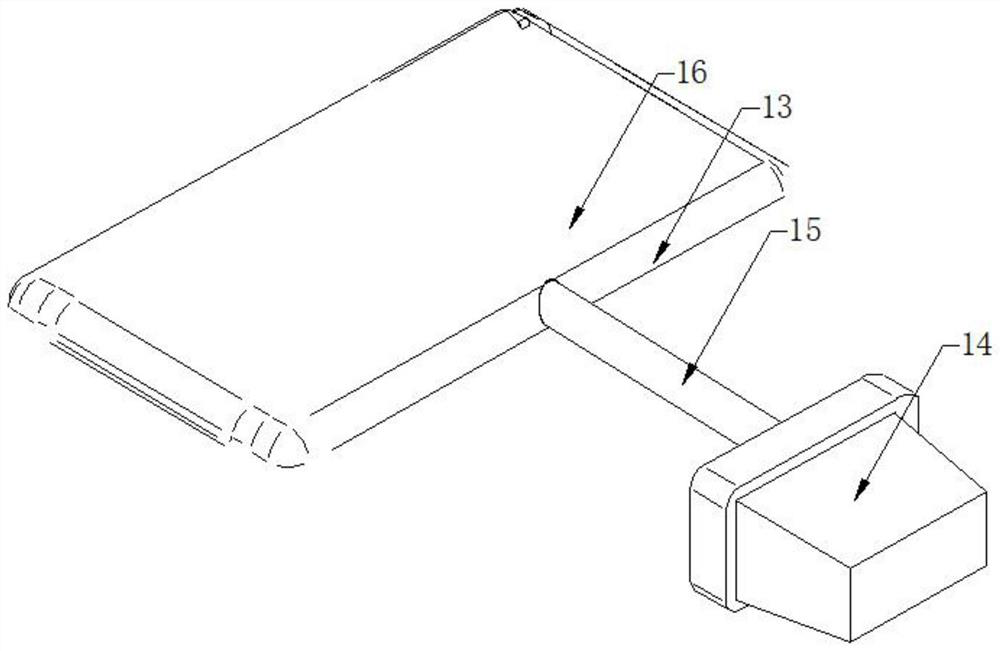

[0029] like Figure 1-4 As shown, the present invention provides a device for producing indoor non-expandable steel structure fireproof coatings, comprising a main body 1, a feeding port 2 is provided on the top of the main body 1, the main body 1 includes a rolling tank 3 and a stirring tank 4, and the rolling tank 3 There is a rolling structure 5 installed inside, and the rolling structure 5 is located on one side of the feed port 2. The rolling structure 5 includes a hydraulic driver 6, a transmission shaft 7 and a rolling plate 8, and one end of the hydraulic driver 6 is connected with a transmission shaft 7. , one end of the transmission shaft 7 is connected with a rolling plate 8, and a stirring device 9 is arranged inside the stirring tank 4. The stirring device 9 includes a driving motor 10, a stirring shaft 11 and a stirring rod 12, and one end of the driving motor 10 is connected with a stirring shaft 11. One end of the stirring shaft 11 is connected with a stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com