Sound quality evaluation method based on CEEMD and CWD

An evaluation method and sound quality technology, applied in the field of sound quality evaluation based on CEEMD and CWD, can solve the problems such as the sound quality improvement and design requirements of manufacturers that cannot meet the customer's sound preference, and there is no correlation, so as to preserve the time-frequency characteristics. , avoid modal overlap, improve the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

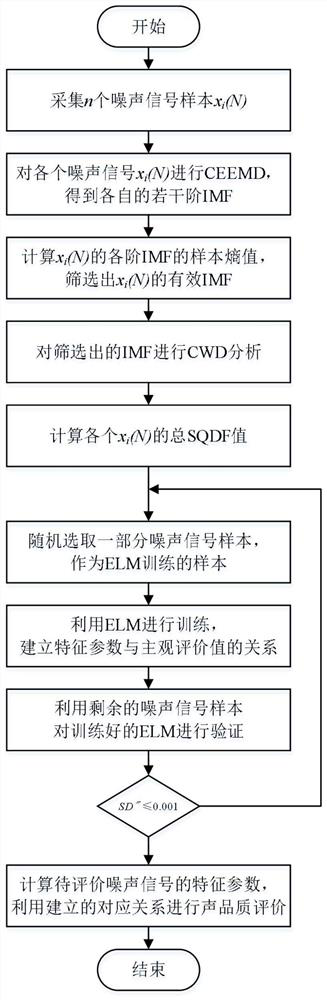

[0152] This embodiment provides a sound quality evaluation method based on CEEMD and CWD, including the following steps:

[0153] Step 1: Collect the air intake noise of a long-head truck. In this experiment, a total of 8 vehicles' right air intake noise data were collected, and three sets of data were collected for each sample vehicle. Finally, a total of 24 noise signal samples were obtained. And select 20 evaluators with normal hearing to evaluate the sound quality of each noise signal sample. This evaluation adopts a graded scoring method, which is scored according to the irritability of the noise on a 10-point scale. Finally, each noise signal sample is subjective The average value of the evaluation is used as the final subjective evaluation score, and the final subjective evaluation results of these 24 noise signal samples are shown in Table 1;

[0154] Table 1 Subjective evaluation results of noise signal samples

[0155] sample number subjective evaluation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com