Air purification system of clean workshop in electronic industry

An air purification system and clean workshop technology, applied in the field of air purification, can solve the problems of low purification efficiency, poor purification effect, and low floor space of the air purification system, achieve good dust removal effect, increase service life, and prevent secondary Flappy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

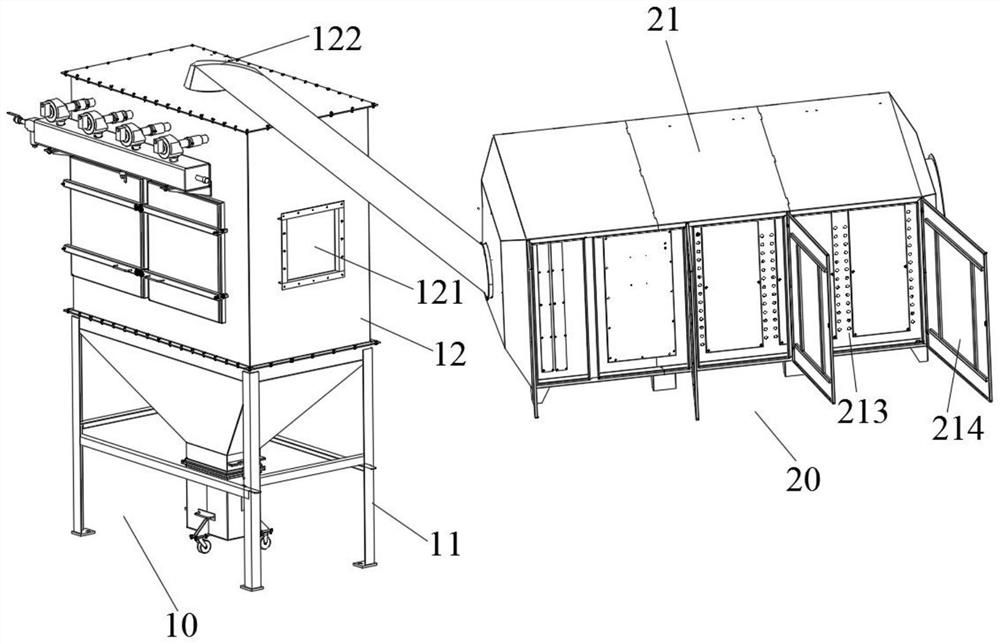

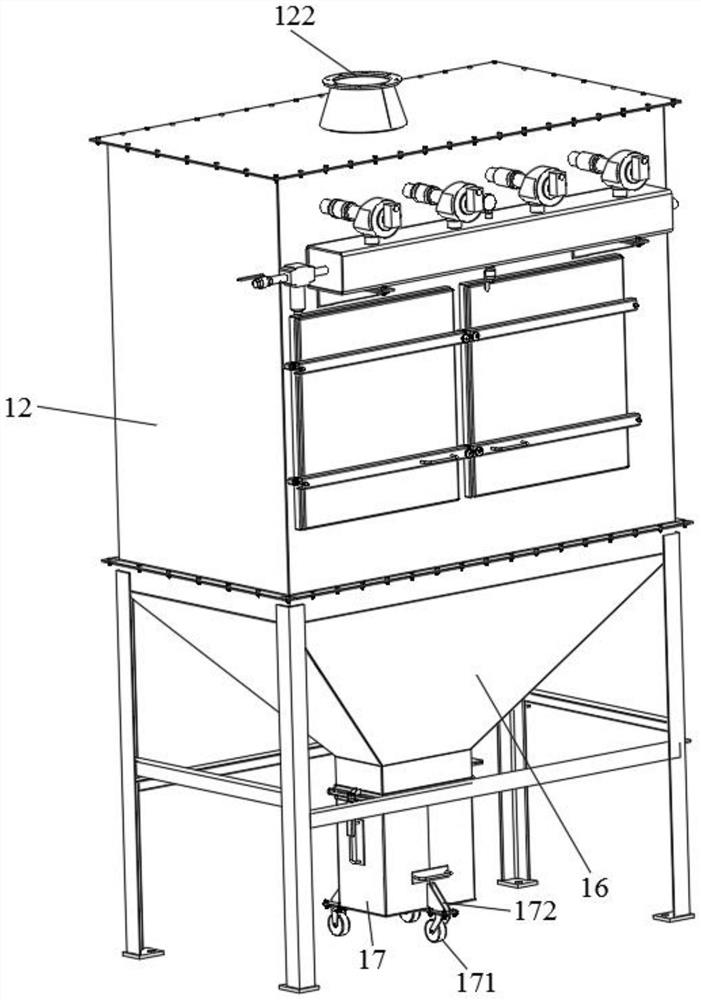

[0024] The present invention is as Figure 1 to Figure 5 As shown, an air purification system for an electronic industry clean workshop includes a dust removal device 10 for dedusting the air and a purification device 20 for purifying the air, wherein:

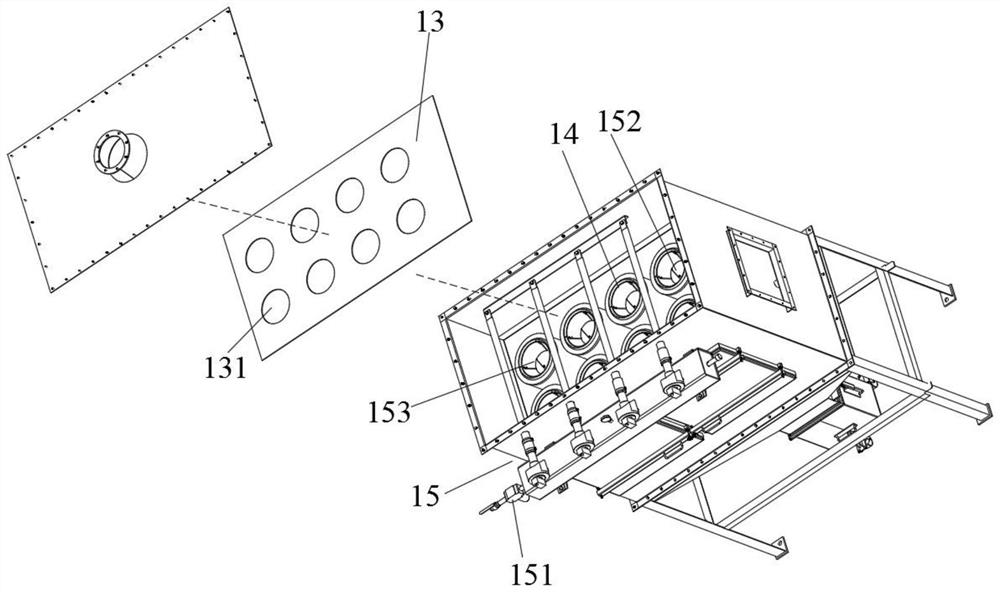

[0025] The dust removal device 10 includes a support frame 11, a dust removal box 12, a cloth bag 14, a dust cleaning assembly 15, an ash hopper 16 and an ash collection box 17; the dust removal box 12 is installed on the support frame 11; the side wall of the dust removal box 12 An air inlet 121 for entering air and an air outlet 122 for discharging purified air are provided. The cloth bag 14 is installed in the dust removal box 12, and a partition 13 is arranged above the cloth bag 14. There is a through hole 131 for air to pass through; the ash hopper 16 is connected under the dust removal box 12; the ash collecting box 17 is detachably installed under the ash hopper 16; the ash cleaning assembly 15 includes an electromagne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap