Isolator riveting tool

A one-way device and riveting technology, which is applied in the field of riveting tooling, can solve the problems of unstable riveting quality, low riveting efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

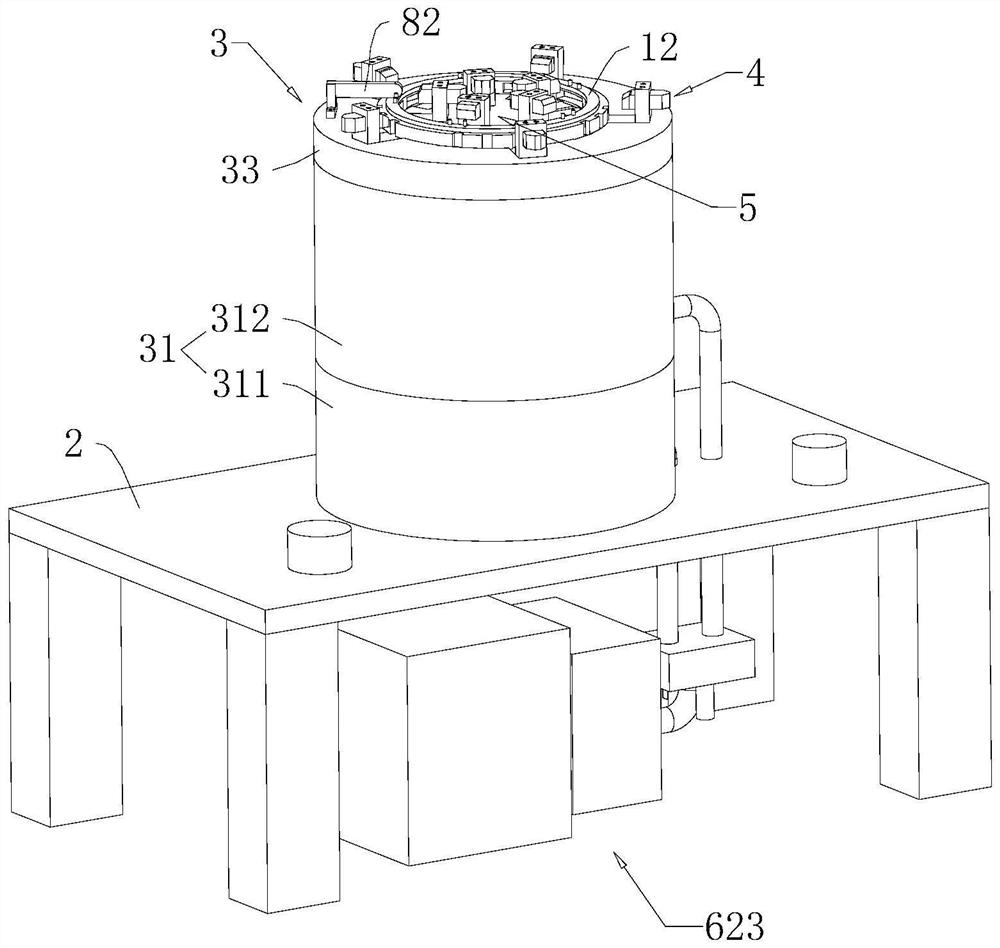

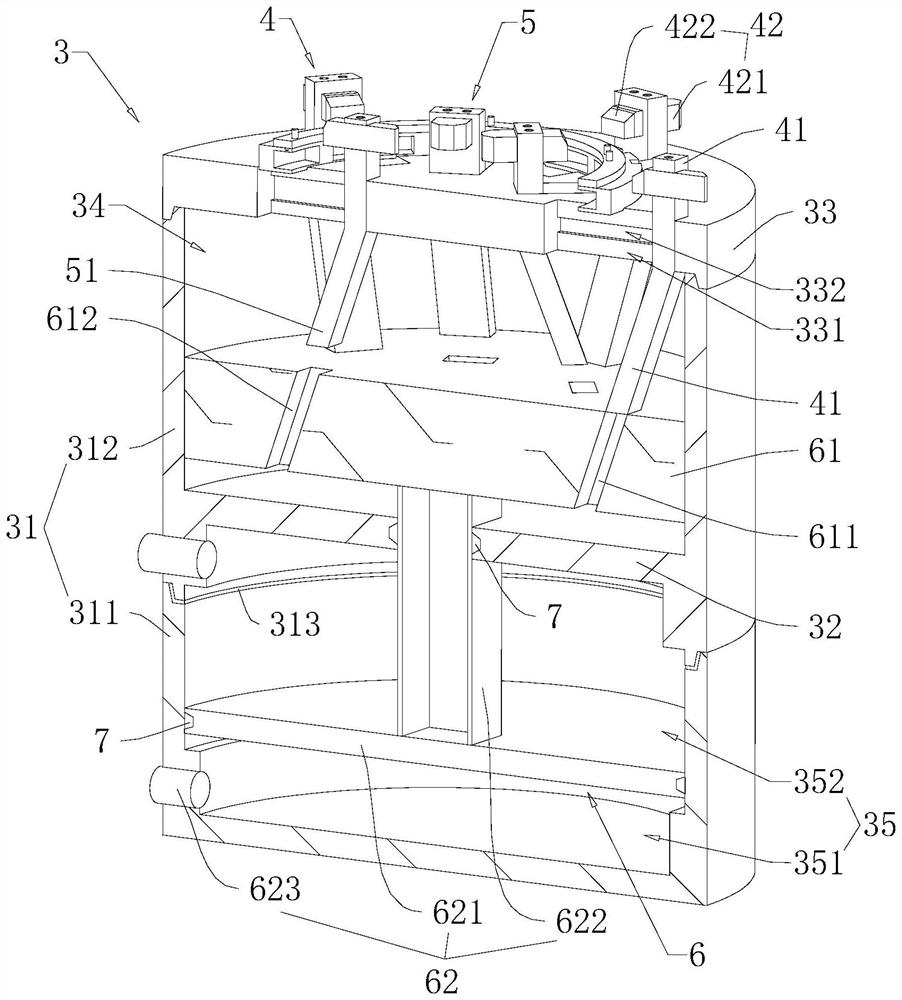

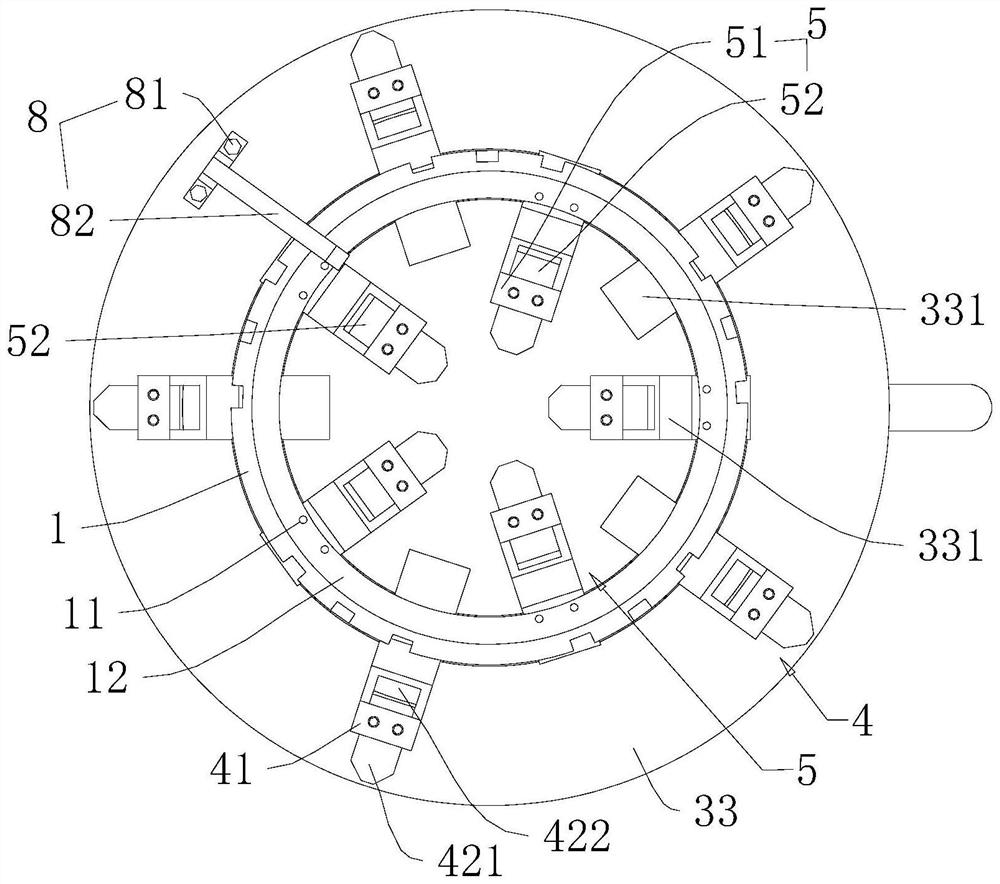

[0035] Attached below Figure 1-3 The present invention will be further described.

[0036] refer to figure 1 and figure 2 , the embodiment of the present invention proposes a one-way device riveting and pressing tool, including a workbench 2, a riveting and pressing table 3 and a riveting and pressing mechanism. The wheel 1 and the cage 12, and the riveting work of the rivet 11 is carried out by the riveting and pressing mechanism.

[0037] The riveting table 3 includes a main body 31 , a partition 32 and a cover plate 33 ; the main body 31 has an upper opening structure as a whole, which includes a first main body 311 fixed on the worktable 2 and having an upper opening structure, and a first main body 311 connected to the first main body 311 The second main body 312 at the upper opening, so that the main body 31 can be divided into a first main body 311 and a second main body 312; An air pressure cavity 35 is formed between the bottoms of the first main body 311 ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com