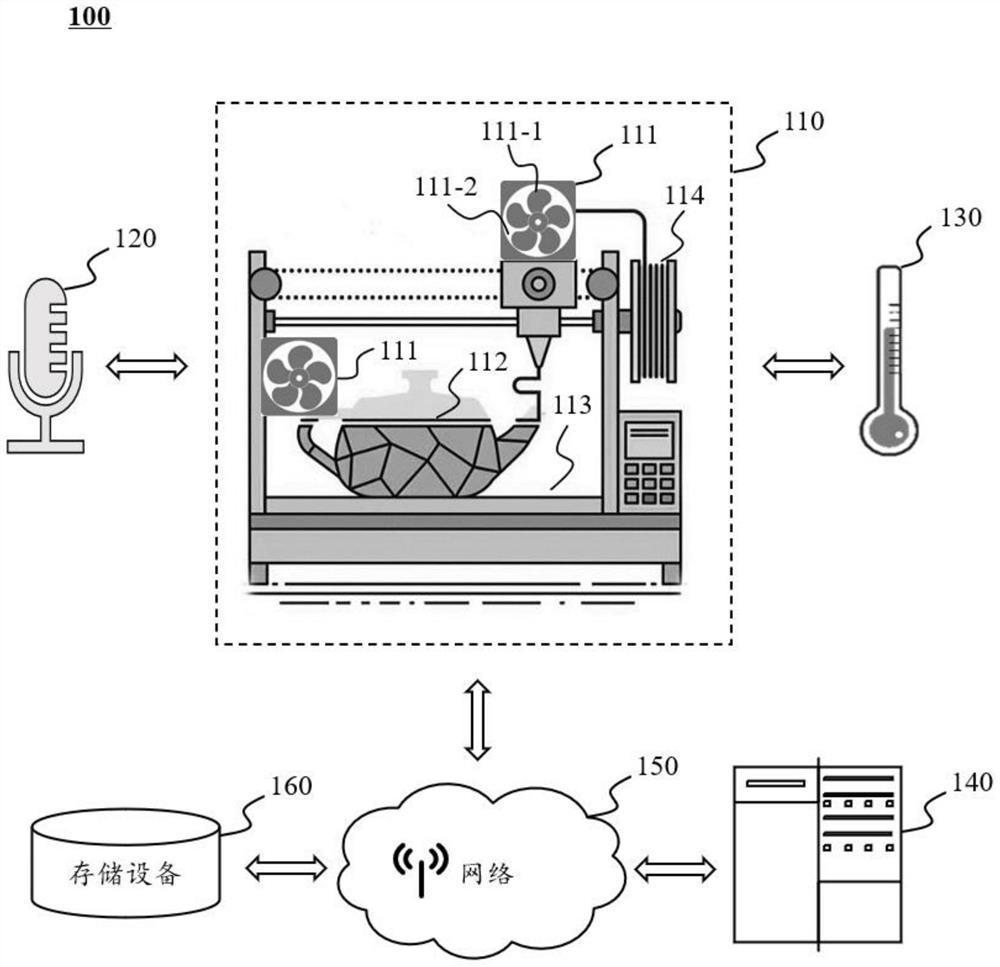

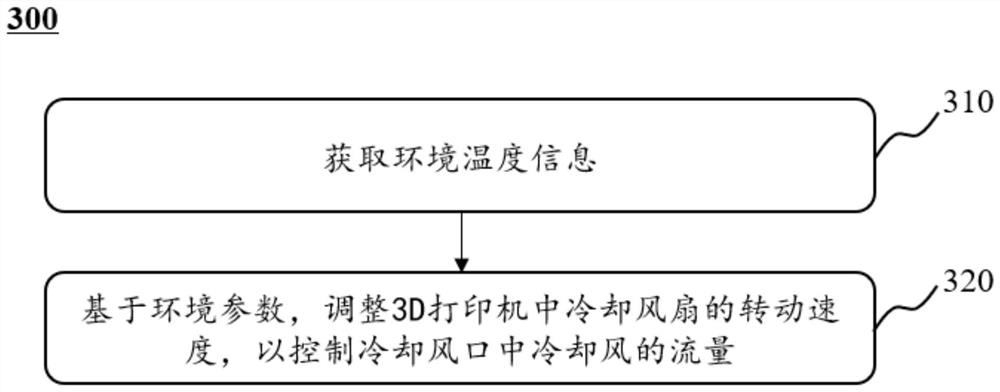

3D printing mold cooling method and system

A mold cooling and 3D printing technology, applied in the field of 3D printing, can solve problems such as affecting the quality of material molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to illustrate the technical solutions of the embodiments of the present specification more clearly, the following briefly introduces the accompanying drawings that are used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some examples or embodiments of the present specification. For those of ordinary skill in the art, the present specification can also be applied to the present specification according to these drawings without any creative effort. other similar situations. Unless obvious from the locale or otherwise specified, the same reference numbers in the figures represent the same structure or operation.

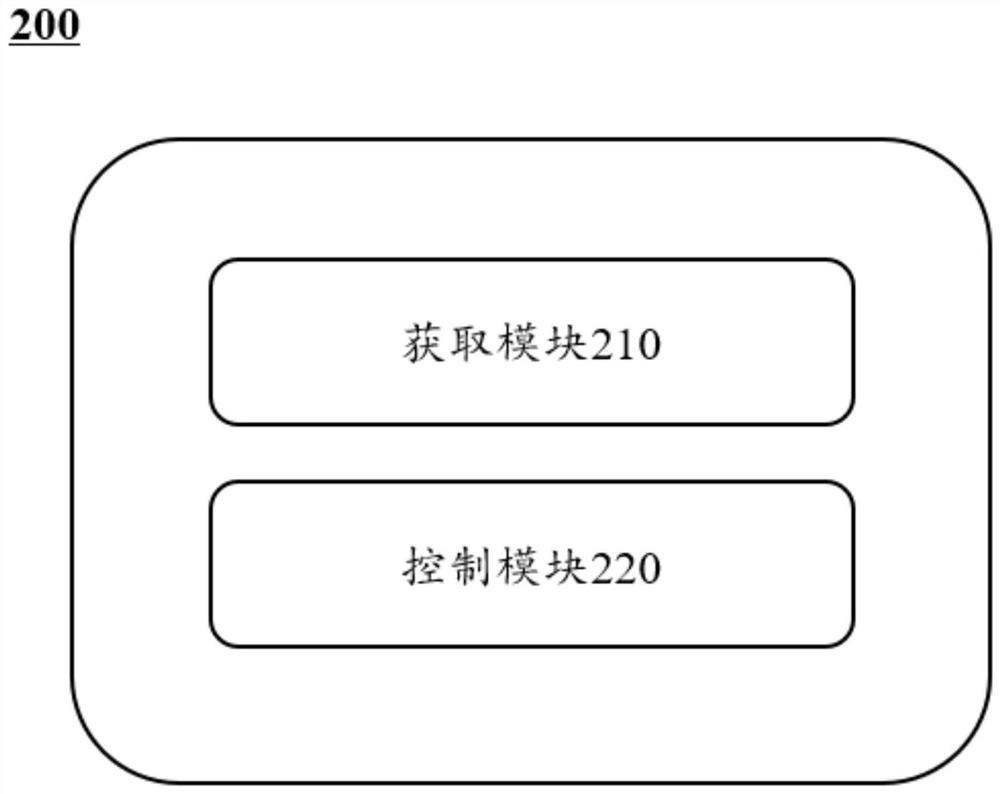

[0015] It should be understood that "system", "device", "unit" and / or "module" as used herein is a method used to distinguish different components, elements, parts, sections or assemblies at different levels. However, other words may be replaced by other expressions if they serve the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com