Method for determining specification of metal wire for hose, and hose

A technology for metal wires and hoses, applied in the direction of hoses, pipes/pipe joints/fittings, pipes, etc., to achieve the effect of improving pressure resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

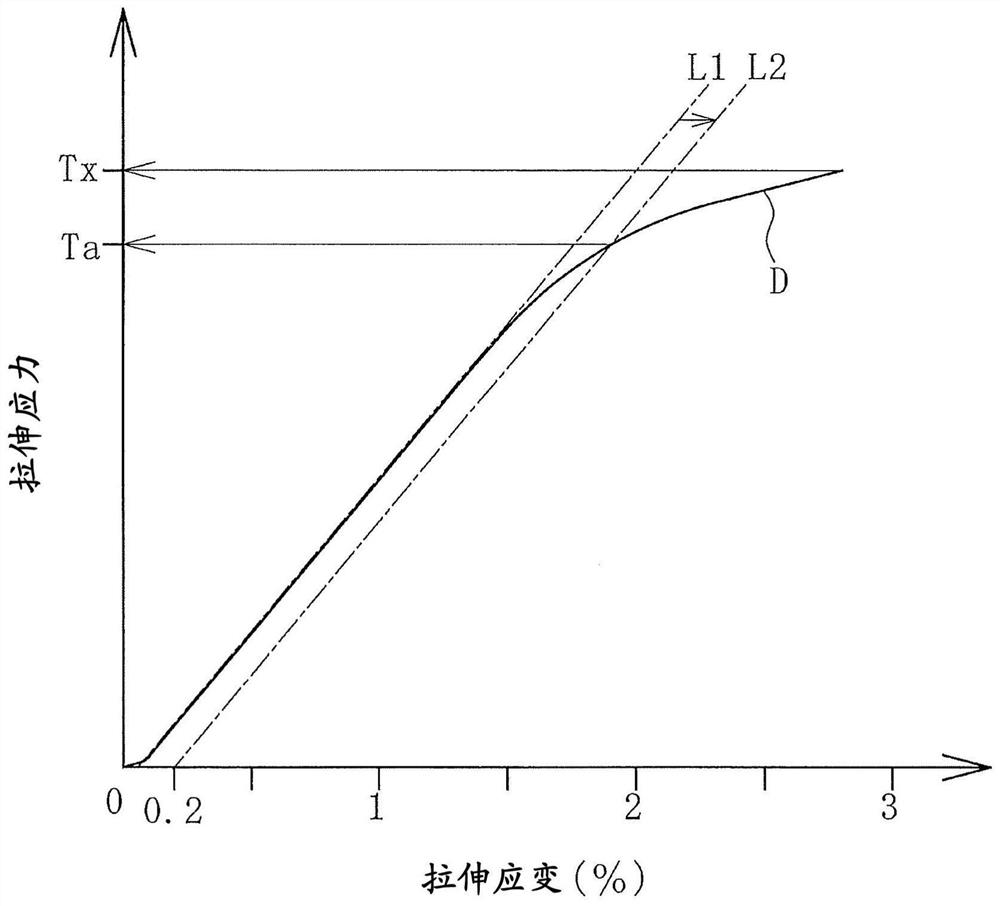

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the specification determination method and the hose of the wire for hoses of this invention are demonstrated based on embodiment shown in drawing.

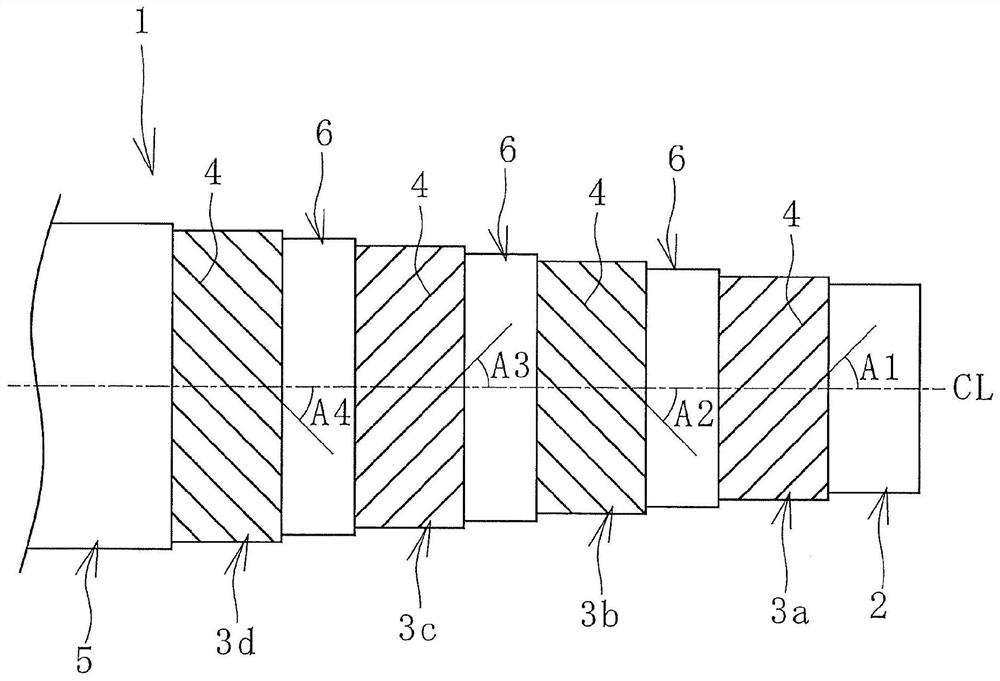

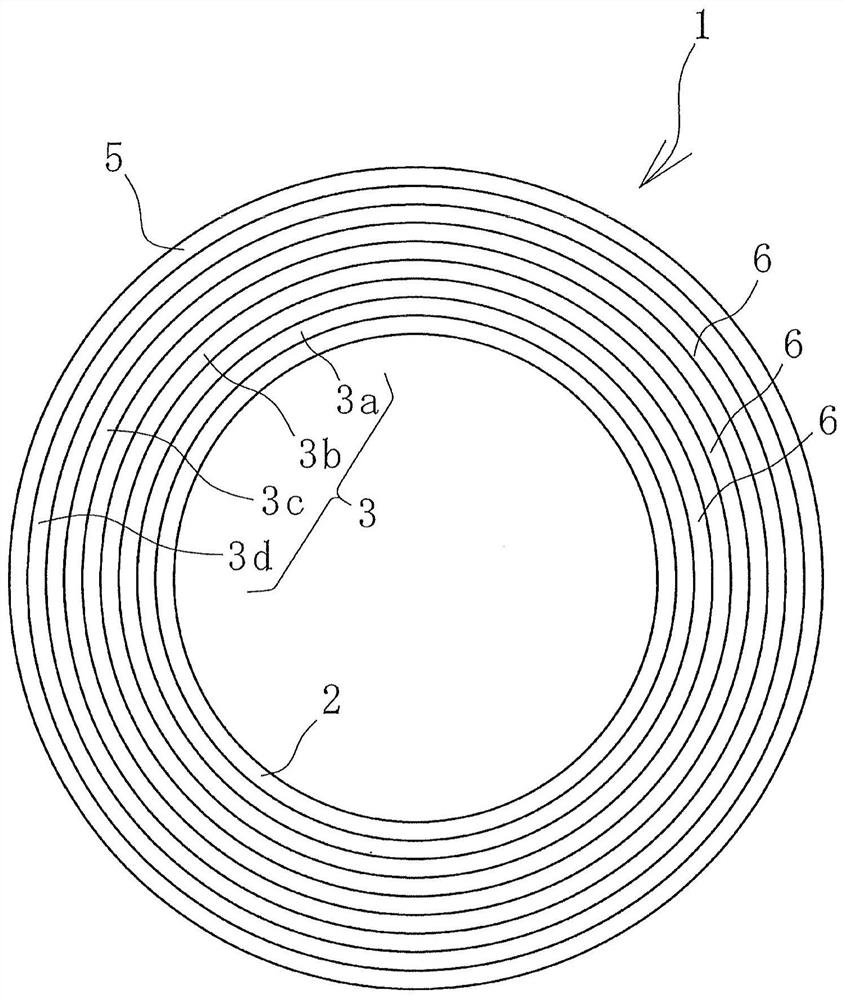

[0029] figure 1 , figure 2 The illustrated embodiment of the hose 1 of the present invention is used as a so-called hydraulic hose or a hose for an air conditioner that circulates a refrigerant of an air conditioner for a vehicle. The hose use pressure is, for example, the hose 1 belonging to the category of high-pressure hoses of 15 MPa or more and 50 MPa or less. The hose outer diameter is, for example, 20 mm or more and 75 mm or less, and the hose inner diameter is, for example, 10 mm or more and 55 mm or less.

[0030] In this hose 1, the inner surface layer 2, the reinforcement layer 3 (3a, 3b, 3c, 3d) and the outer surface layer 5 are laminated|stacked coaxially in this order from the inner peripheral side. Furthermore, the interlayer rubber layer 6 is interposed between the reinforcing layers 3 stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com