Micro-channel evaporator and working method thereof

An evaporator and micro-channel technology, which is used in evaporators/condensers, refrigerators, lighting and heating equipment, etc., can solve problems such as incompatibility, uneven refrigerant, and impact on heat exchange performance of heat exchangers. performance, uniform distribution of refrigerant, and the effect of reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

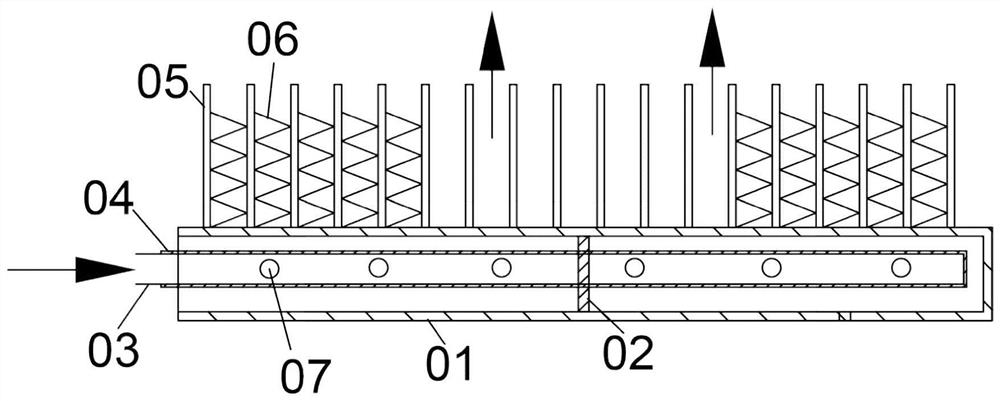

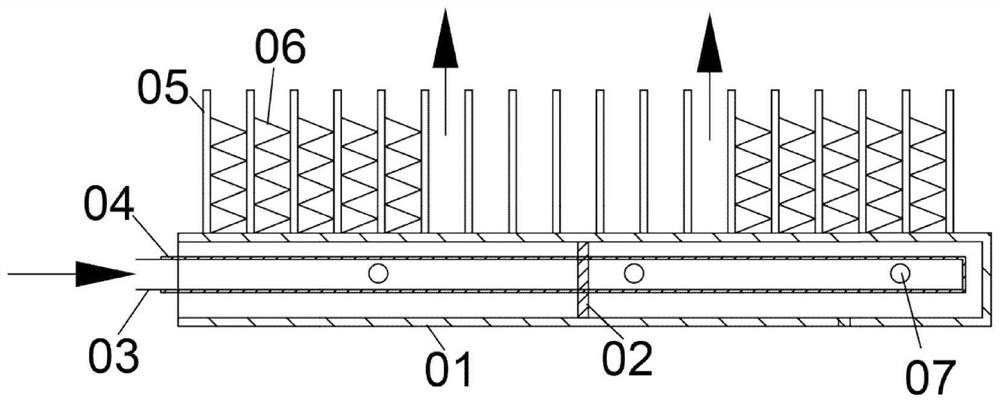

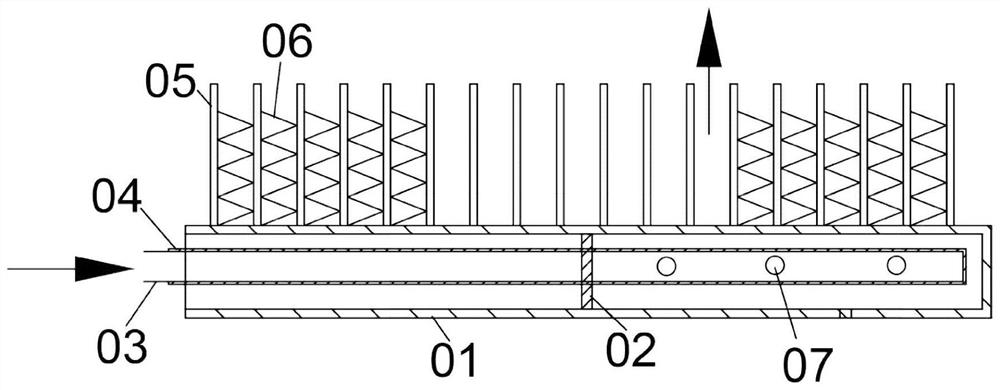

[0022] like figure 1 , figure 2 , image 3 As shown, a micro-channel evaporator includes a liquid collecting pipe 01, a partition plate 02, a first distribution pipe 03, a second distribution pipe 04, a plurality of flat pipes 05 inserted into the liquid collecting pipe 01, and a plurality of flat pipes 05 installed in adjacent flat pipes The fins 06 in between, the partition plate is installed in the middle of the liquid collecting pipe 01, the second distribution pipe 04 is sleeved on the first distribution pipe 03, and both the first distribution pipe 03 and the second distribution pipe 04 have distribution holes 07 . The first distribution pipe 03 is fixed, the second distribution pipe 04 can be rotated, and at the same time, such as Figure 4 As shown, there is only one row of distribution holes 07 on the first distribution pipe 03...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com