Cover for fiber optic ferrule and ferrule pusher

A technology for fiber optic sleeves and pushers, which is applied in the field of covering parts for optical fiber sleeves and sleeve pushers, and can solve the problem of damage to the sleeve pusher or optical fiber of the optical fiber sleeve, scratching the optical fiber, easy generation of debris or Dust and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

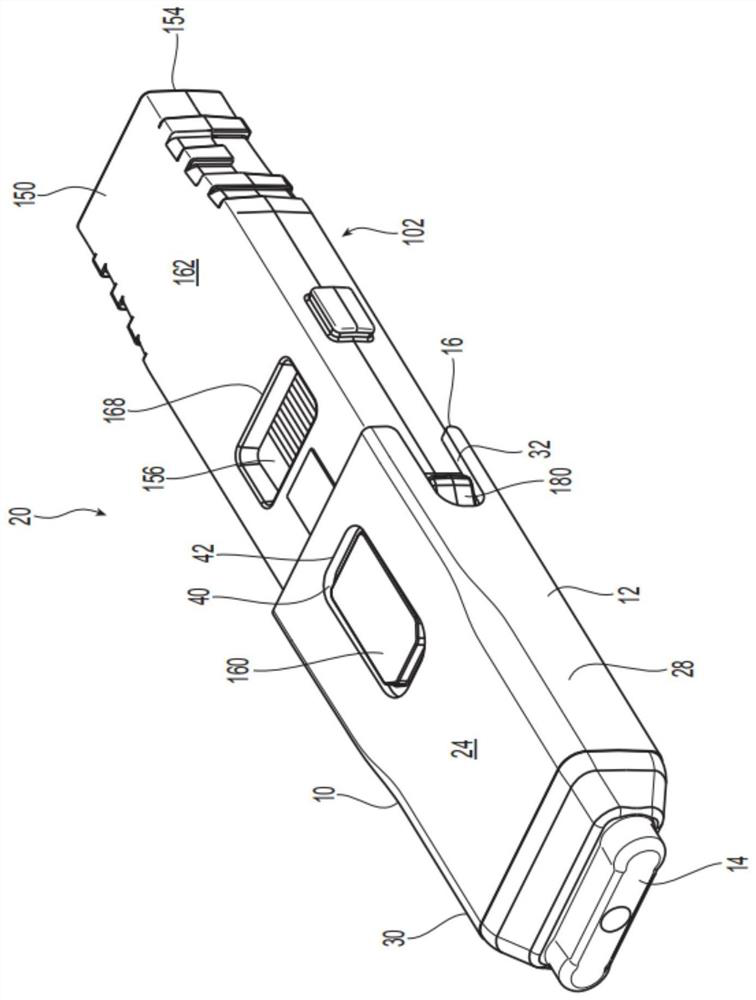

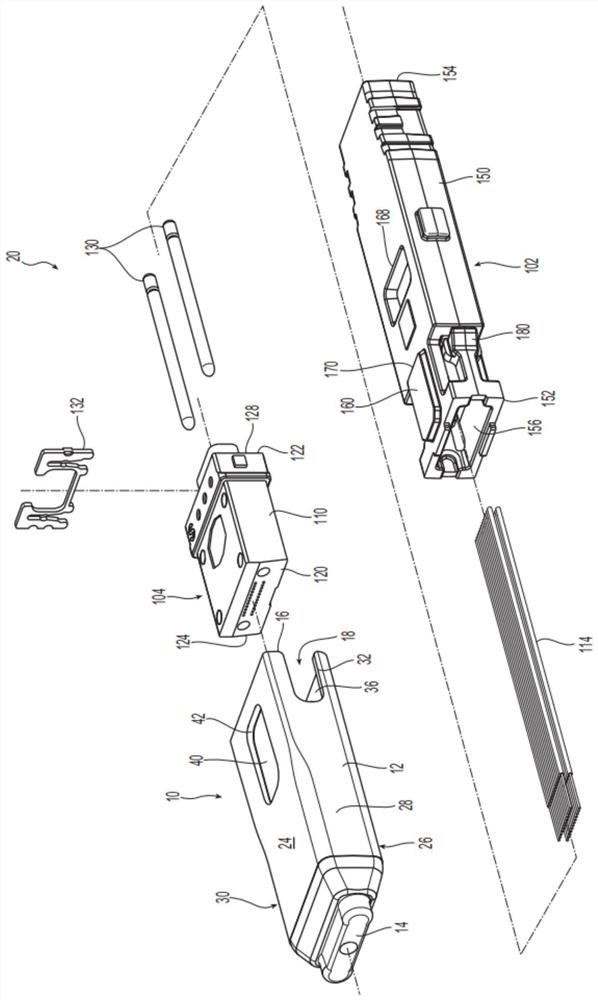

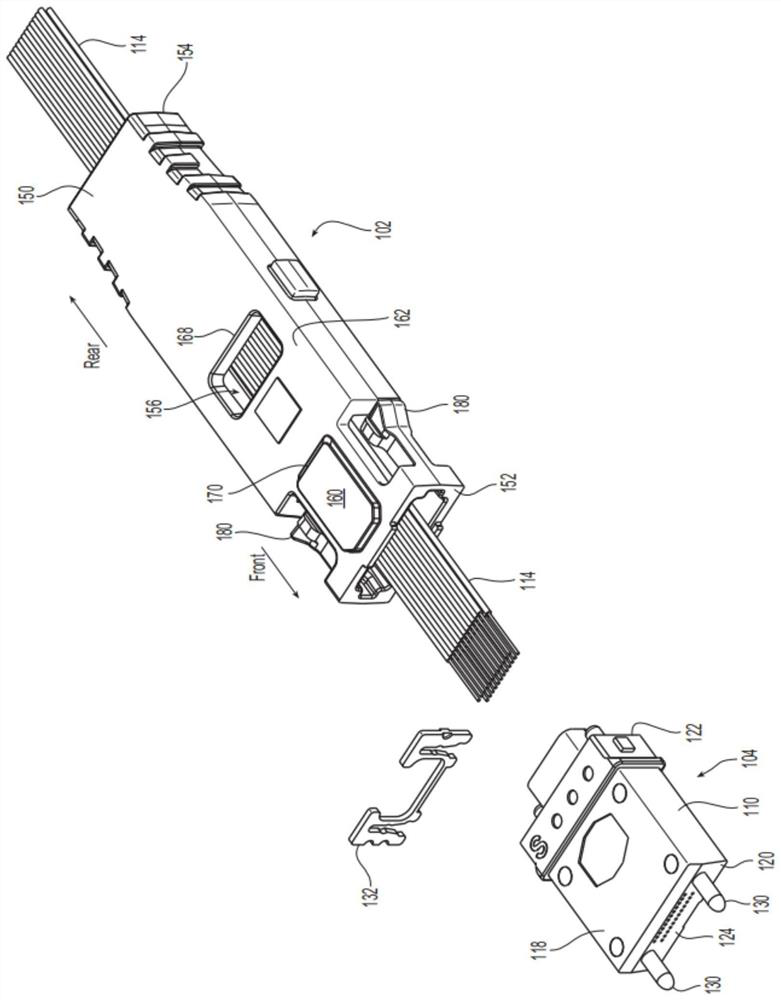

[0032] Reference will now be made in detail to one or more presently preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0033] Applicants note that the term "front" or "forward" means the direction in which a fiber optic connector and / or ferrule will meet another fiber optic connector or device, whereas the use of the term "rear" or "rearward" means Refers to the direction from which the fiber enters the fiber optic ferrule, fiber optic connector, or ferrule pusher. Thus, each component will have a front and a back, and the two front or forward portions of the fiber optic ferrule will be joined to each other. Thus, in figure 1 , the "front" of the fiber assembly is located figure 1 to the left and "forward" is towards the left and out of the page. "Backward" or "rear" is the portion of the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com