Building workpiece spraying equipment with automatic circulating movement and compression function

A technology of automatic circulation and spraying equipment, applied in the direction of spraying device, etc., can solve the problems of reducing the uniformity of equipment spraying power utilization efficiency, insufficient efficiency of construction workpieces, inconvenient for integrated movement of construction workpieces, compression spraying, etc., so as to improve utilization efficiency and improve all-round effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

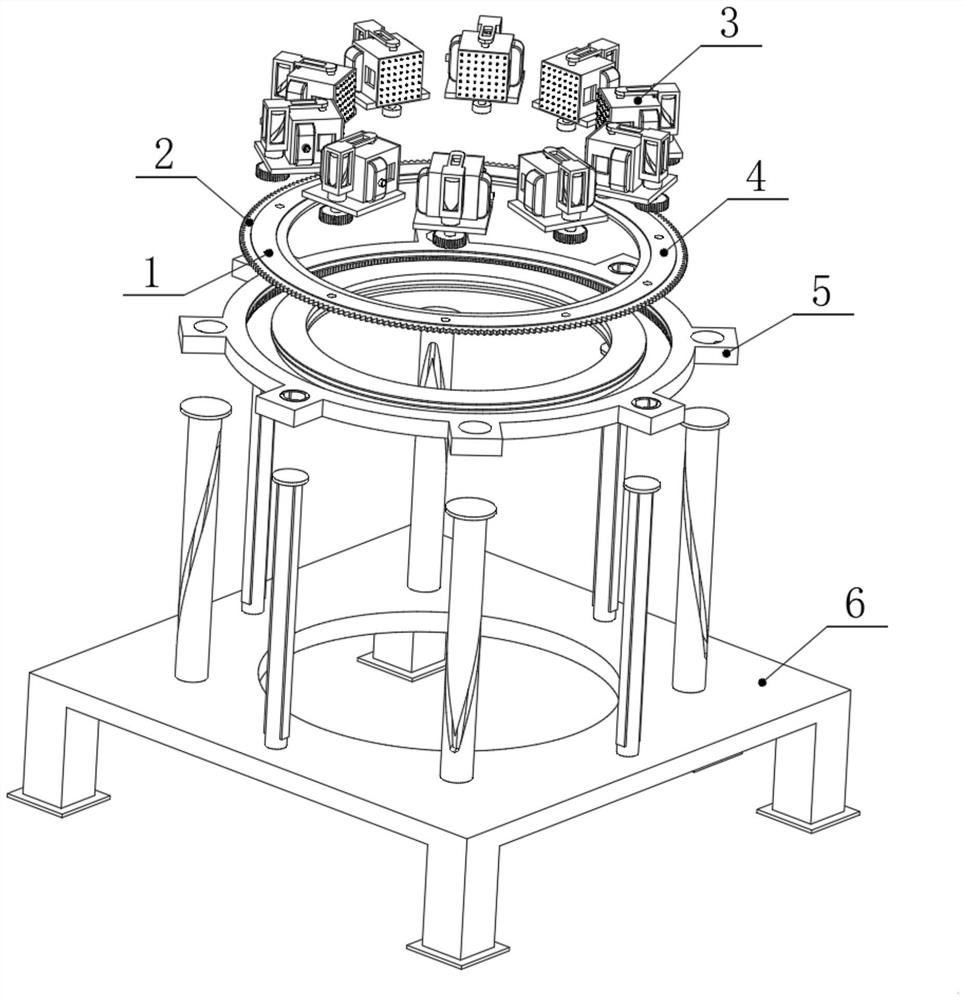

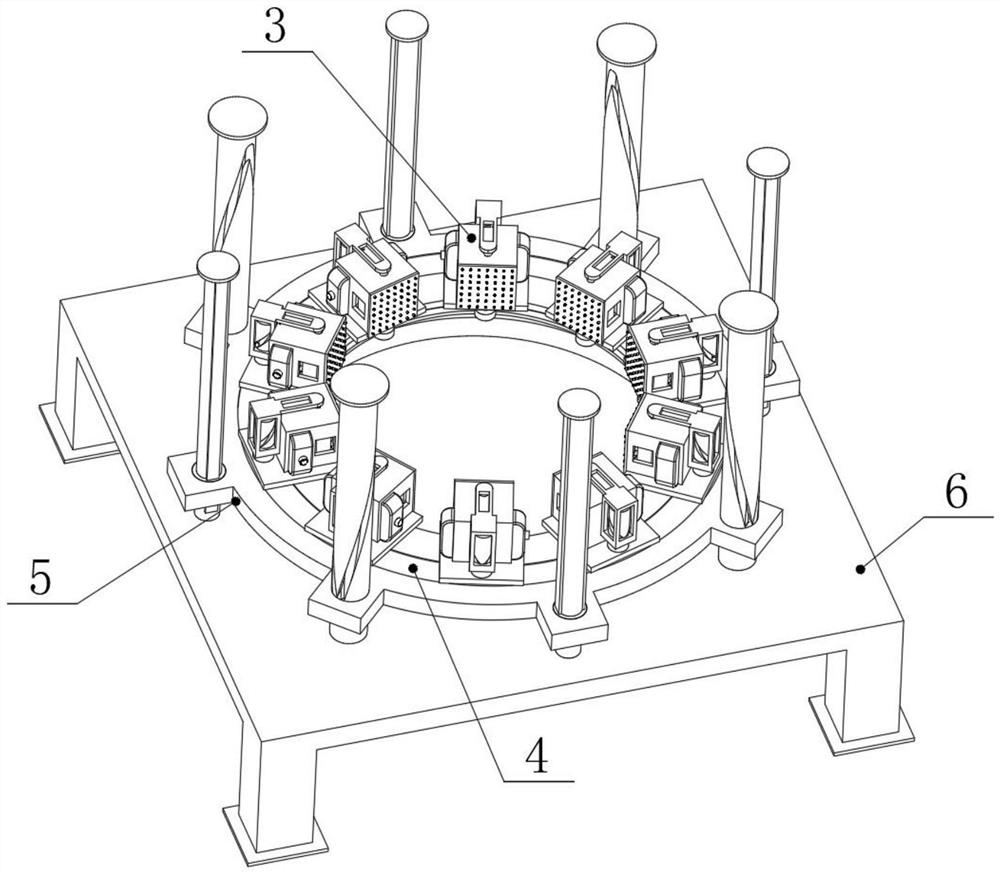

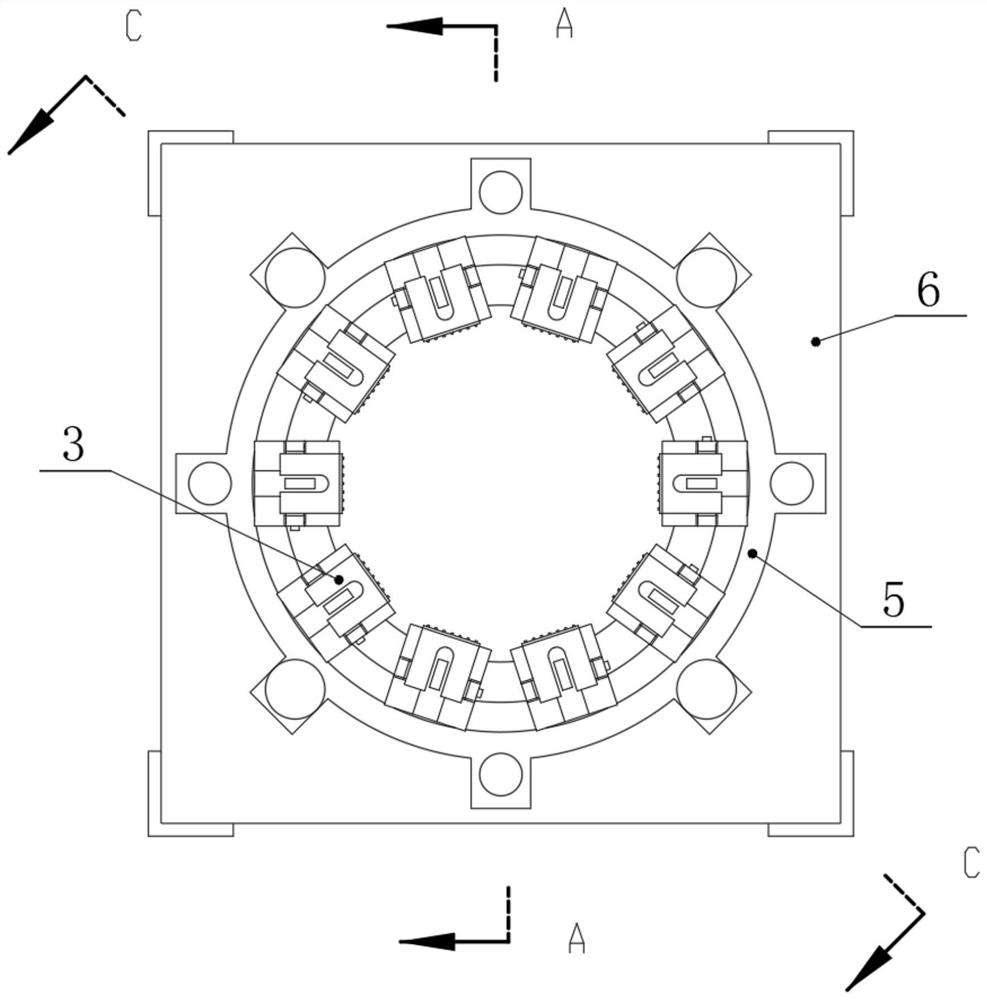

[0037] see Figure 1-13, an embodiment provided by the present invention: a construction workpiece spraying equipment with automatic circular movement and compression, including a transmission device 6 for guiding and supporting, and a guiding device 5 is slidably clamped on the upper end surface of the transmission device 6 , and the inner end face of the guide device 5 is rotatably connected with a support swivel 4, the upper end face of the support swivel 4 is evenly equidistant from the bottom to open a limited rotation groove 1, and the center of the side end face of the support swivel 4 is fixedly installed with The gear ring 2 is connected, and the inner end surface of the guide device 5 is evenly meshed and slidably connected with the spray device 3 through the connection gear ring 2 .

[0038] like Figure 8 , Figure 9 , Figure 10 and Figure 11 , the spraying device 3 includes a plate-shaped high-pressure spray head 31, a sealing compression plate 32, a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com