High-entropy alloy foam structure multi-electron beam additive manufacturing method

A high-entropy alloy and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problem that the strength and toughness of composite materials cannot reach an ideal state, and achieve the effects of shortening forming time, refining grains, and good stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A multi-beam electron beam additive manufacturing method for a high-entropy alloy foam-like structure provided by the present invention comprises the following steps:

[0074] (1) AlCoCrFeNiTi will be prepared according to the mass percentage of Al: 9.75%, Co: 21.30%, Cr: 18.77%, Fe: 20.22%, Ni: 21.20%, Ti: 8.66% 0.5 High-entropy alloy particles, after screening, take AlCoCrFeNiTi of 30 ~ 80μm 0.5 High-entropy alloy powder, atomized, stored in vacuum, and ready for use;

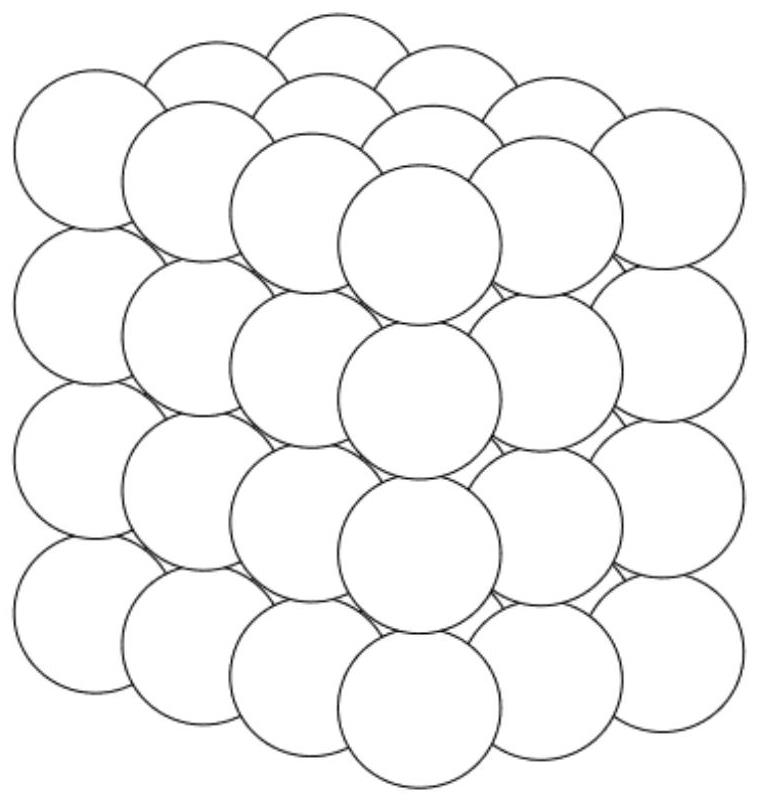

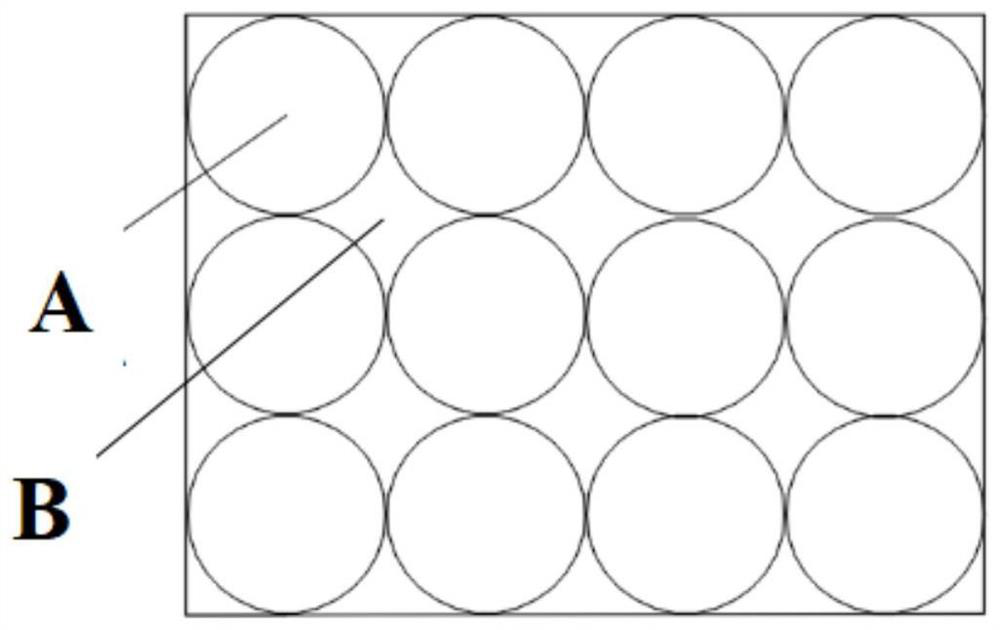

[0075] (2) The three-dimensional model of the foam structure of the additive component is established by computer software. The "foam" workpiece includes several spherical A areas distributed according to the requirements, and there are gaps B between the adjacent four spherical A areas. In the process of increasing the electron beam upward, one by one, circular thin layers of different sizes are piled up to form a spherical A area, and then multiple spherical A areas are arranged and scanned to compl...

Embodiment 2

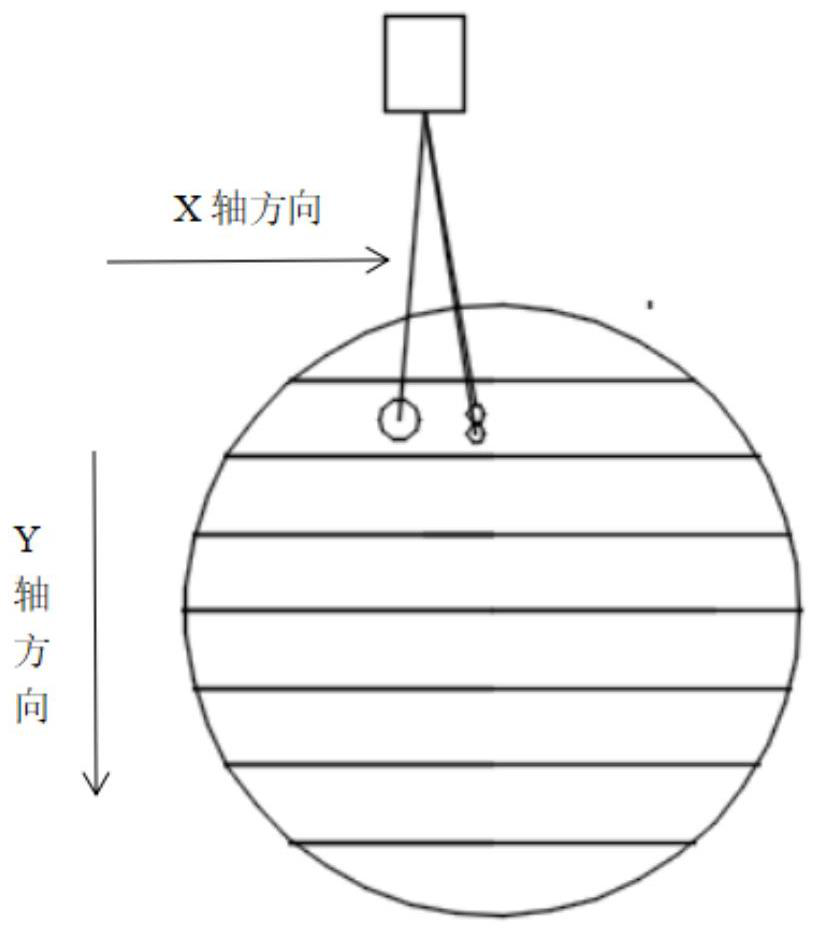

[0089] Based on the additive manufacturing method of Embodiment 1, Embodiment 2 provides an alloy multi-beam electron beam additive manufacturing equipment, such as Figure 5 As shown, the additive manufacturing equipment includes a processing chamber 13 with a hollow structure inside, an electron beam inlet window is arranged on the top of the processing chamber 13, and an electron beam emission box 8 is arranged outside the processing chamber 13 and located just above the electron beam inlet window. , the inside of the electron beam emission box 8 is facing the electron beam entrance window from top to bottom and sequentially set the cathode 1, the condenser electrode 2, the anode 3, the combined axis 4, the auxiliary focus 5, and the main focus 6 for the scanning of the multi-beam electron beam 12. , the deflection coil 7, and the multi-beam electron beam 12 perform scanning operations; a material chamber 14 communicated with the processing chamber 13 is arranged below the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap