High-frequency vibration type propeller

A high-frequency vibration and thruster technology, applied in electric components, power devices, electromechanical devices, etc., can solve the problems of unsuitable development needs for modernization, high manufacturing costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

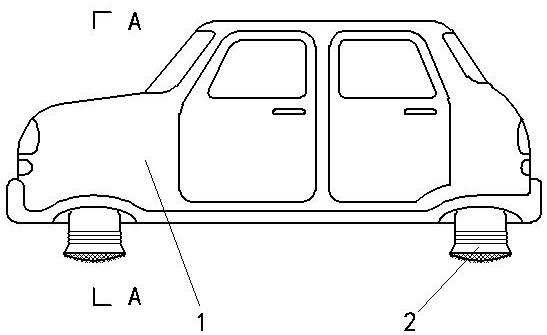

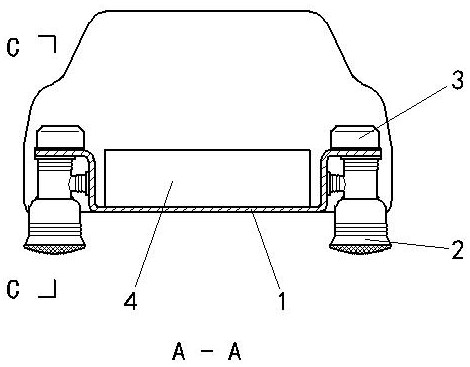

[0025] exist image 3 , Figure 4 , Figure 7 , Figure 8 Among them, the fixed iron core 16 is a vertical cylindrical structure, a vertical hole is opened at the axial position of the upper end of the fixed iron core 16, a coil 15 is arranged on the column wall of the lower end of the fixed iron core 16, and in the middle of the fixed iron core 16 A horizontal hole perpendicular to the fixed iron core 16 is opened on the column wall of the horizontal hole, and the bottom surface of the horizontal hole is set as a spherical surface structure. The moving iron core 14 is of a concave cylindrical structure, a coil 15 is arranged on the wall of the concave hole of the moving iron core 14, and the lower end of the fixed iron core 16 is inserted into the concave hole of the moving iron core 14. 16. The movable iron core 14 and the coil 15 together constitute a reciprocating electromagnetic vibration mechanism. The two ends of the half shaft 12 are respectively provided with a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com