A Parking Brake with Braking Force Automatic Compensation Function

A parking brake and automatic compensation technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of insufficient parking brake torque, attenuation of spring force, parking landslide, etc., and achieve ingenious structural design. , to achieve a solid connection, improve the effect of vehicle safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

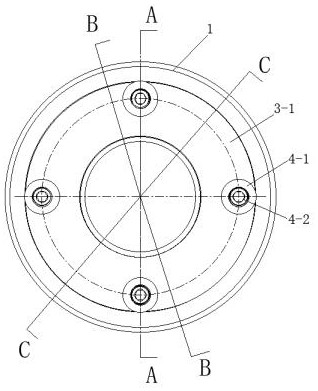

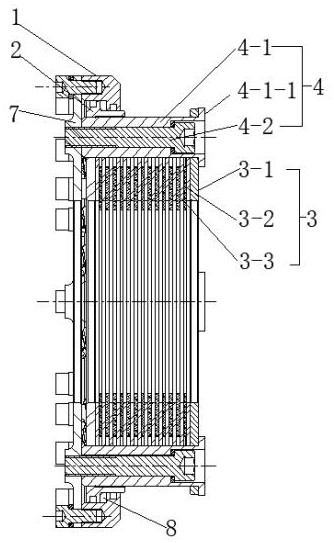

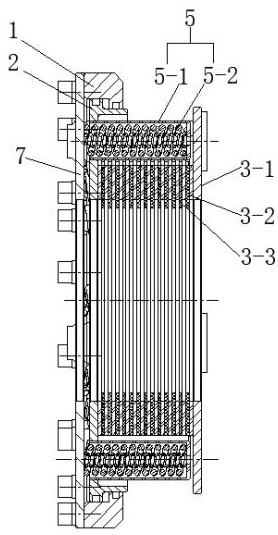

[0048] like Figure 1 to Figure 4 The shown parking brake with automatic braking force compensation function includes a brake cylinder 1 , a piston 2 , a brake assembly 3 , a support guide 4 , a parking elastic assembly 5 , a compensation device 6 and a spring cover 7 . The spring cover 7 is fixedly installed on the left side of the brake cylinder 1 , the piston 2 is arranged in the brake cylinder 1 and can move axially, and the brake assembly 3 is arranged in the inner cavity of the piston 2 . The supporting guide device 4 , the parking elastic assembly 5 and the compensating device 6 are provided in multiples and distributed evenly along the circumference of the piston 2 . The left end of support guiding device 4 is fixedly installed on the spring cover 7, and the right end extends to the rear end of brake assembly 3 and limits the position when brake assembly 3 initial states; Fixedly connected, when the brake assembly 3 wears out, the compensation device 6 can compensate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com