Separating material returning type blocky food forming mold

A technology of food molding and material return, applied in food forming, food science, application, etc., can solve problems such as low mold return efficiency, difficult return of materials, food damage, etc., to improve convenience and increase return efficiency , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

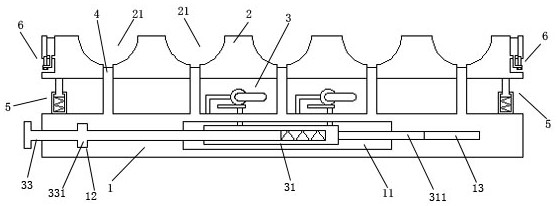

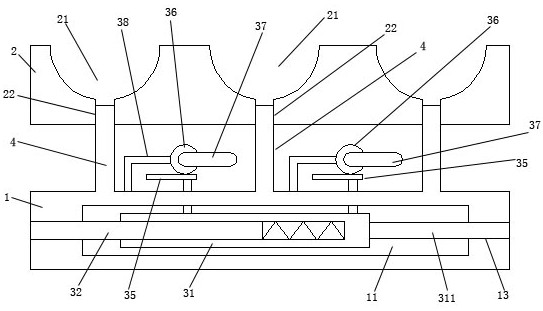

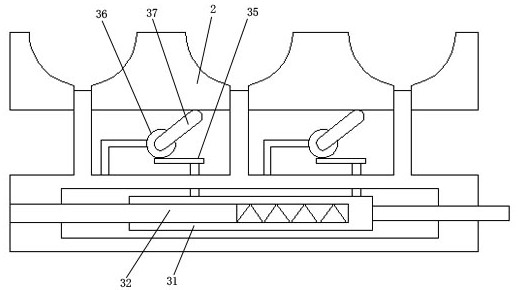

[0023] The content of the present invention will be further described in detail below with reference to the accompanying drawings.

[0024] like Figures 1 to 5 As shown, a separate-returning block-shaped food forming mold comprises a base 1, a mold plate 2, an elastic support mechanism 5, a material-returning column 4, and a separation pressing mechanism 3; a mold plate 2 is installed on the upper end of the base 1; The upper end of the base 1 is evenly installed with a plurality of return columns 4; the upper end surface of the die plate 2 is evenly provided with a plurality of die grooves 21; the bottom of the die groove 21 is respectively provided with a communicating conducting groove 22; The upper ends of the ejection columns 4 are respectively connected in the conducting grooves 21; a plurality of elastic support mechanisms 5 are evenly installed between the lower end of the die plate 2 and the upper end of the base 1; the elastic support mechanisms 5 elastically squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com