Device for testing friction performance of clutch friction plate

A friction performance and testing device technology, applied in measuring devices, mechanical devices, workpiece clamping devices, etc., can solve the problem of difficulty in ensuring the fit between the friction plate and the detection head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

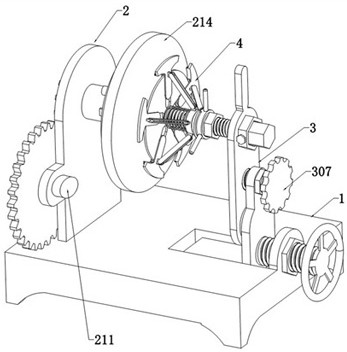

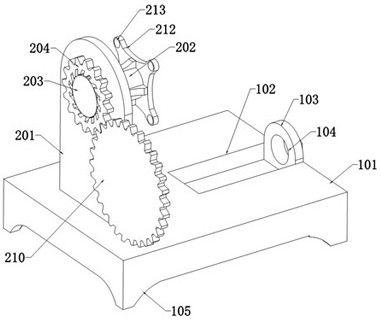

[0030] The present invention provides such as Figure 1 to Figure 10 A friction performance test device of a clutch friction plate as shown includes a supporting assembly 1, a rotating assembly 2, an adjusting assembly 3 and a clamping assembly 4, and the two ends of the upper surface of the supporting assembly 1 are respectively provided with a rotating assembly 2 and an adjusting assembly 3, A clamping assembly 4 is arranged between the rotating assembly 2 and the adjusting assembly 3 .

[0031] The support assembly 1 includes a support base 101. A chute 102 is provided in the middle of one end of the upper surface of the support base 101. A support plate 103 is fixedly connected to one end of the slot of the chute 102. The four corners of the lower surface of the seat 101 are fixedly connected with feet 105 .

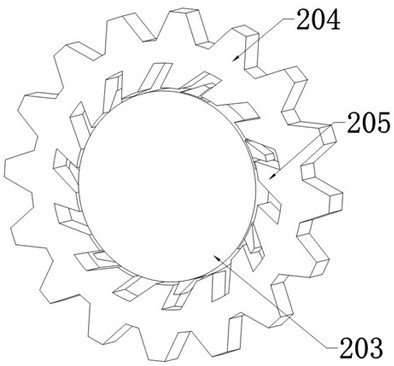

[0032] The rotating assembly 2 includes a fixed plate 201, the middle of the fixed plate 201 is movably connected with a rotating rod 202 through a bearing, one end...

Embodiment 2

[0041] Based on the previous embodiment, under the long-term use of the above-mentioned device, it is easy to cause different degrees of wear of the clamping block 405. Since the position of the clamping block 405 is determined by the position of the movable sleeve 410, the above-mentioned device cannot be adjusted according to the degree of wear of the clamping block 405. The clamping block 405 is closely attached to the friction plate. At the same time, due to the different thickness of the friction plate, the above device cannot adjust the clamping position of the clamping block 405 and the friction plate according to the thickness change of the friction plate. If the thickness of the friction plate is smaller than the clamping block 405, As a result, the clamping block 405 protrudes from the friction plate, which affects the performance detection of the friction plate. If the thickness of the friction plate is larger than that of the clamping block 405, the clamping area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com