Material friction and wear performance testing device and testing method

A technology of friction and wear and testing methods, which is applied in the direction of testing wear resistance, etc., which can solve the problems that friction and wear performance cannot be realized, surface friction is difficult to realize, temperature and force cannot be adjusted in real time, etc., and the detection results are accurate and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

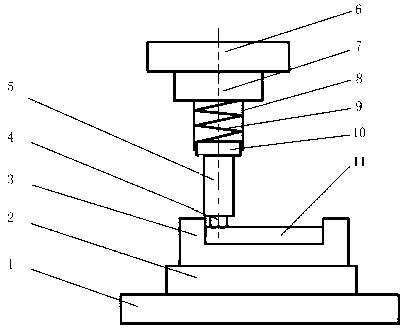

[0018] The invention provides a material friction and wear performance testing device, which is characterized in that it includes a workbench 1, a force measuring device 2, a heatable fixture 3, a universal joint 5 and a CNC machine tool spindle 6; the workbench 1 is provided with a force measuring device 2, A heatable fixture 3 is arranged above the force measuring device 2 , and the spindle 6 of the CNC machine tool is connected with the universal joint 5 . A connection block 7 is arranged below the spindle 6 of the CNC machine tool, the connection block 7 is connected to the cylinder 8, the spring 9 is located inside the cylinder 8, one end of the spring 9 is fixedly connected to the connection block 7, the other end of the spring 9 is fixedly connected to the slider 10, and the slider 10 enters the inside of the cylinder 8, and the lower end of the slider 10 is connected to the universal joint 5.

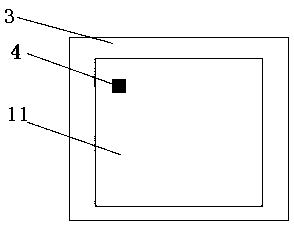

[0019] Material I4 is a single crystal diamond sheet with a size of 5mm×5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com