Diagnosis method and system for industrial control device

A technology for industrial control equipment and diagnostic systems, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as poor experience, inability to remotely diagnose old equipment, and inability to provide industrial control equipment, etc. Achieve the effect of improving work efficiency and user experience, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

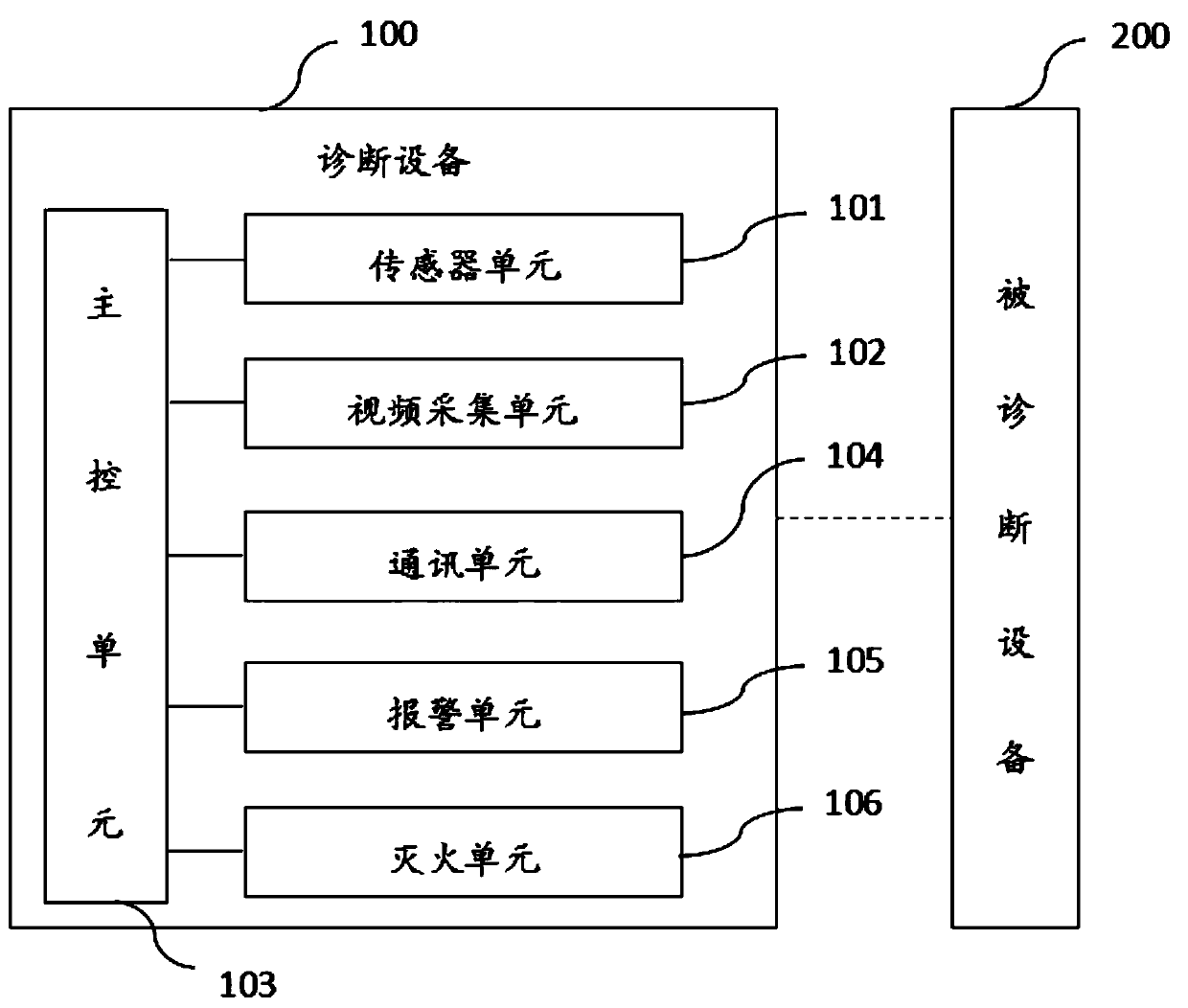

[0039] figure 1 The structure of the diagnostic system for industrial control equipment provided by Embodiment 1 of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows:

[0040] Including diagnostic equipment 100 and diagnosed equipment 200; diagnostic equipment 100 includes:

[0041] The sensor unit 101 is used to detect the power voltage and current of the device under diagnosis 200, the temperature and humidity of the surrounding environment, and the temperature of the casing or the main board;

[0042]The video acquisition unit 102 is used to collect in real time the image of the status indicator light of the diagnosed device 200 or the image of the status display screen, or collect images of the appearance of the diagnosed device 200 and images of objects around the diagnosed device 200; Some old equipment without serial port communication, through ...

Embodiment 2

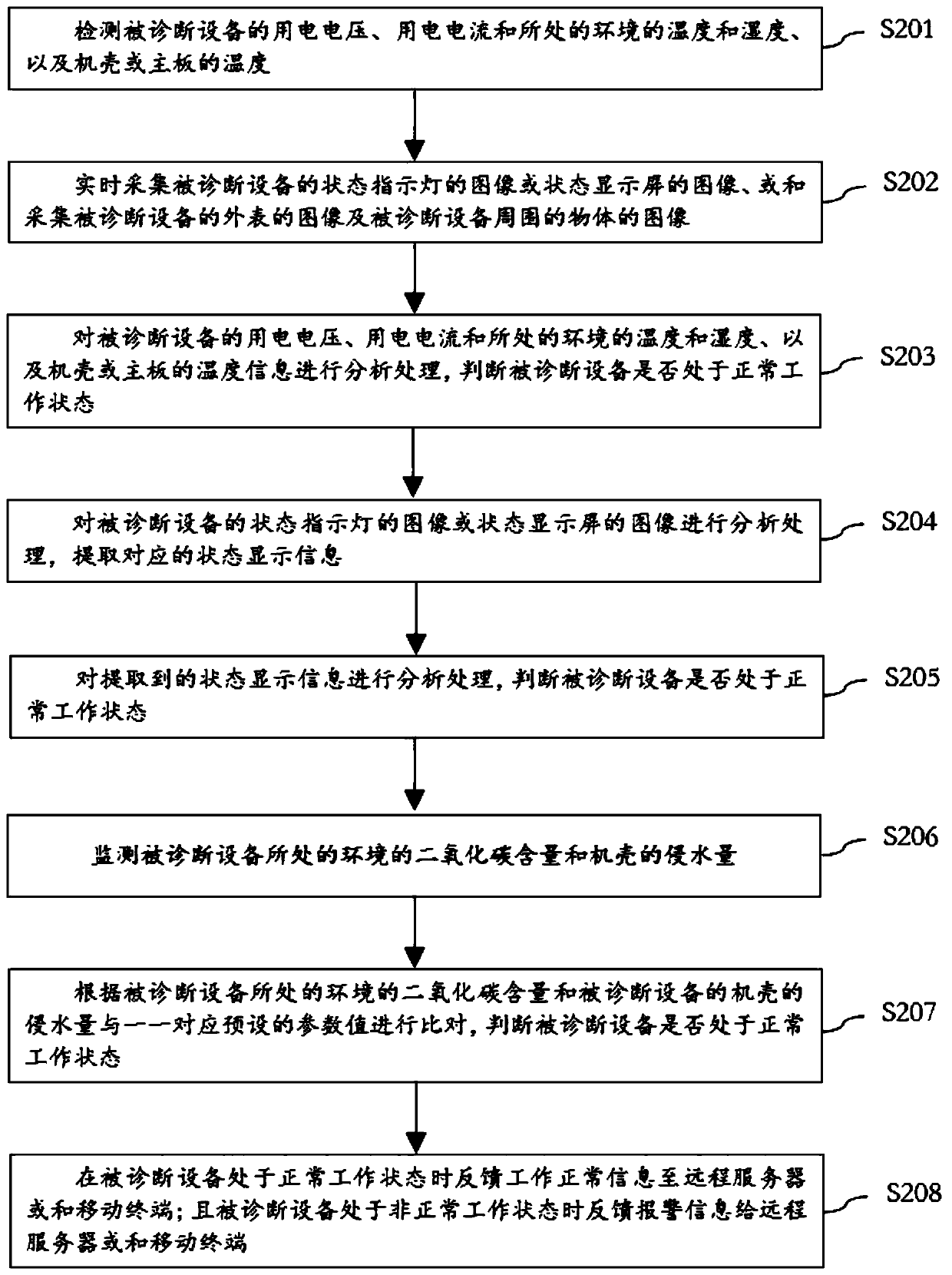

[0055] figure 2 The implementation process of the diagnostic method for industrial control equipment provided by the second embodiment of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows:

[0056] In step S201, the power voltage and current of the device under diagnosis, the temperature and humidity of the surrounding environment, and the temperature of the casing or the main board are detected.

[0057] In step S202, the image of the status indicator light or the status display screen of the device under diagnosis is collected in real time, or the image of the appearance of the device under diagnosis and the images of objects around the device under diagnosis are collected.

[0058] In step S203, analyze and process the power voltage and current of the diagnosed device, the temperature and humidity of the environment, and the temperature information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com