Low-voltage electrical cabinet convenient for busbar maintenance and maintenance method thereof

A technology of low-voltage electrical cabinets and electrical cabinets, which is applied in the direction of electrical components, photovoltaic power generation, busbar/line layout, etc., which can solve problems such as inconvenient inspection, difficult inspection of busbars, and distorted posture, so as to achieve the effect of convenient inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

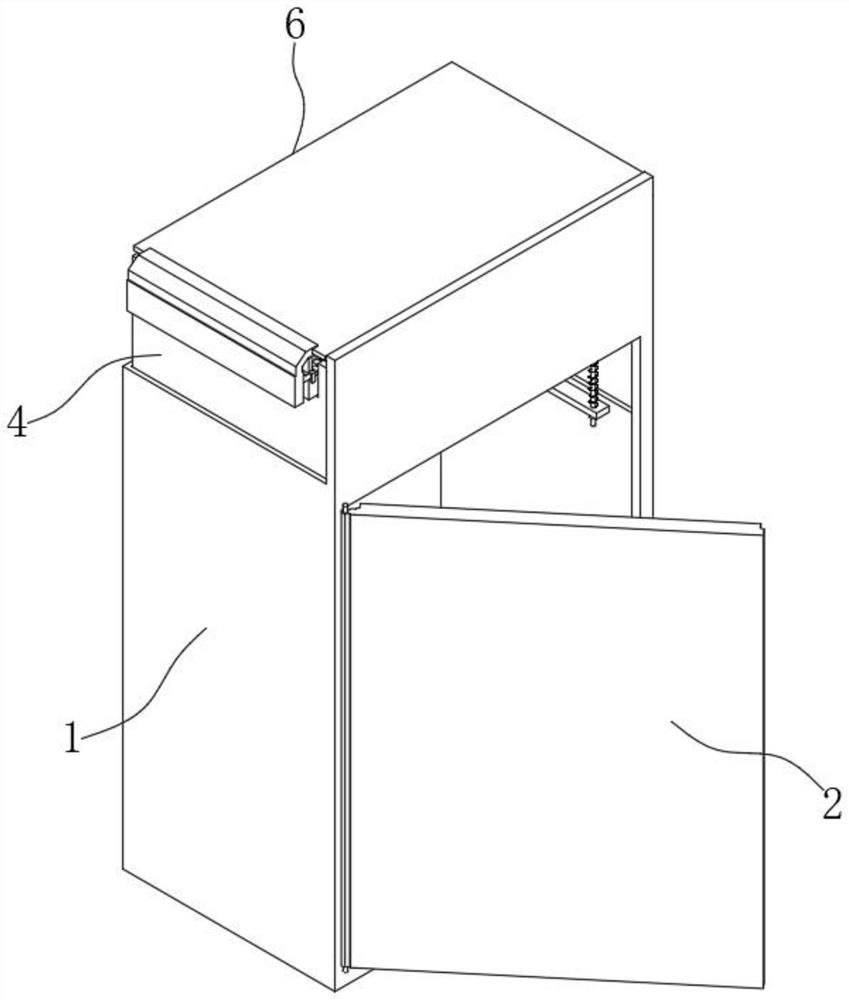

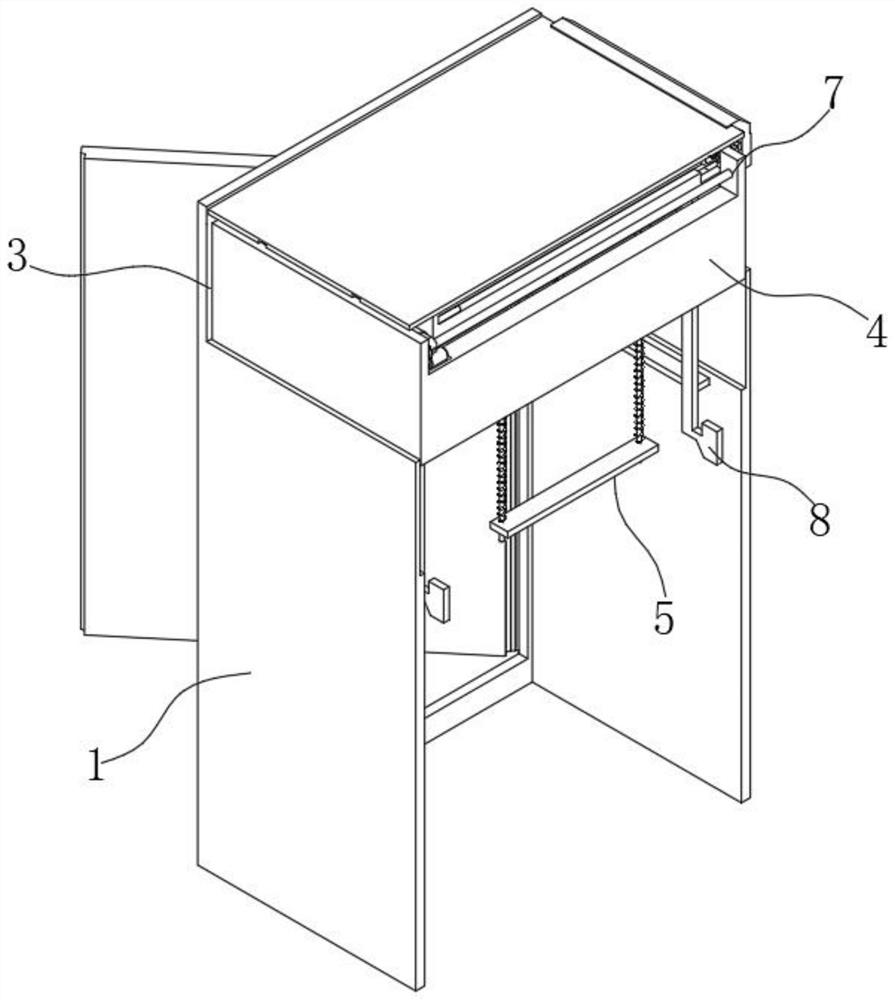

[0030] see figure 1 and figure 2 , a low-voltage electrical cabinet that is convenient for busbar maintenance in the figure includes an electrical cabinet shell 1, a support frame 8 fixed on the inner side of the electrical cabinet shell 1, and a cabinet is installed on one side of the electrical cabinet shell 1 The door 2, and the top of the three sides of the electrical cabinet shell 1 away from the cabinet door 2 is provided with a receiving port 3, the receiving port 3 is provided with a U-shaped plate 4, and the inner side of the U-shaped plate 4 is installed with all the The connecting piece 5 is fixed to the inner wall of the electrical cabinet shell 1. A driving mechanism 7 is installed on the top of the U-shaped plate 4, and the driving mechanism 7 is used for the movement of the movable top cover 6. Busbars are installed.

[0031] In this solution, the electrical cabinet shell 1 is improved, a receiving port 3 for the movement of the U-shaped plate 4 is opened at ...

Embodiment 2

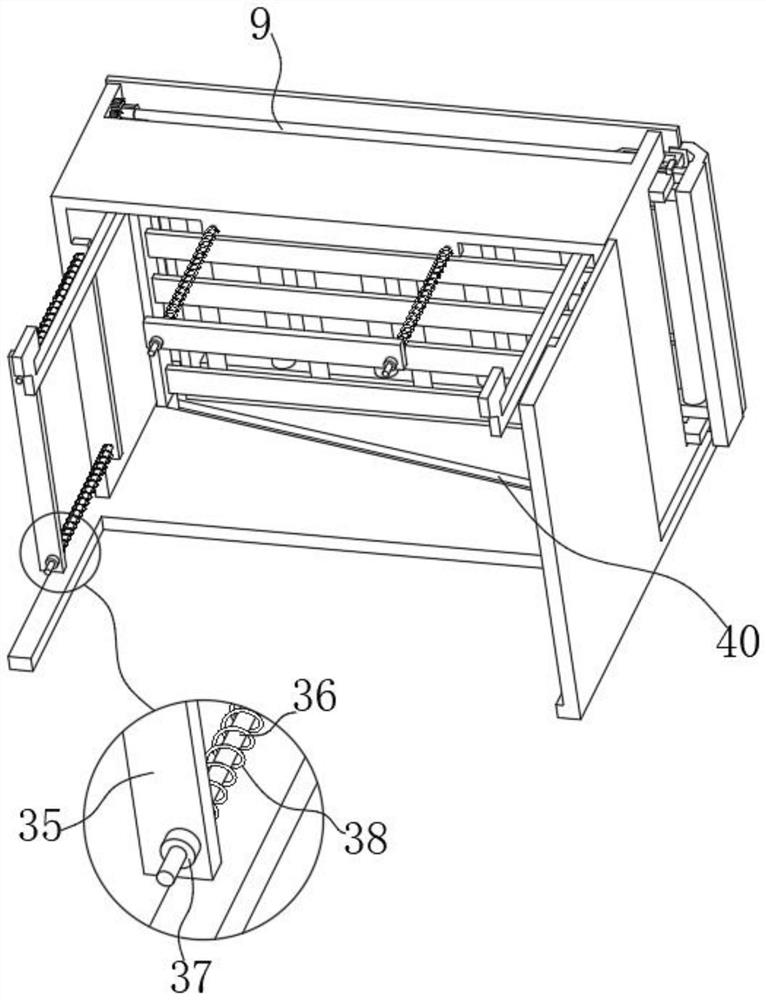

[0048] see Image 6 and Figure 7 In this embodiment, the first embodiment is further described. The clip 21 in the figure includes a docking rod 24 that is slidably inserted into the outer end of the U-shaped frame 16, and the bottom end of the docking rod 24 is located at the sliding port 19. A pressure plate 25 is fixed inside the docking rod 24 , a compression spring 26 for pushing the pressure plate 25 downward is sleeved on the outside of the docking rod 24 , a limiting cap 27 is fixed on the top of the docking rod 24 , and the outer end of the slider 20 is Rounded corners are formed, and both ends of the pressing plate 25 are formed with rounded corners.

[0049] It should be noted that: when the second U-shaped frame 18 is pulled out, the slider 20 and the outer end of the pressure plate 25 will be abutted, so that the pressure plate 25 will move up, so that the slider 20 will move above the card interface 22, and will be pressed against the spring 26. Under the acti...

Embodiment 3

[0054] see image 3 and Image 6 , this embodiment further describes other embodiments, in the figure, a linkage rod 39 is fixed on the outer side of the moving shaft 13, and the inner side of the low-voltage electrical cabinet is provided with a chute 40 that slides and docks with the linkage rod 39;

[0055] It should be noted that: when the moving shaft 13 moves, the linkage rod 39 moves in the chute 40, so that the U-shaped plate 4 can be adjusted up and down, making the adjustment more convenient.

[0056] It should be noted that: when the second U-shaped frame 18 is inserted into the first U-shaped frame 16, it extends under the pressing plate 25 through the limit plate 32, and is clamped with the bayonet 34 through the trapezoidal block 33 at the outer end, so as to realize the limit The position limit of the position plate 32 also realizes the position limit after the U-shaped frame 2 18 is retracted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com