Power supply control device and method for mobile communication base station

A mobile communication base station, power supply control technology, applied to circuit devices, battery circuit devices, substation/switch layout details, etc. problem, to achieve a good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

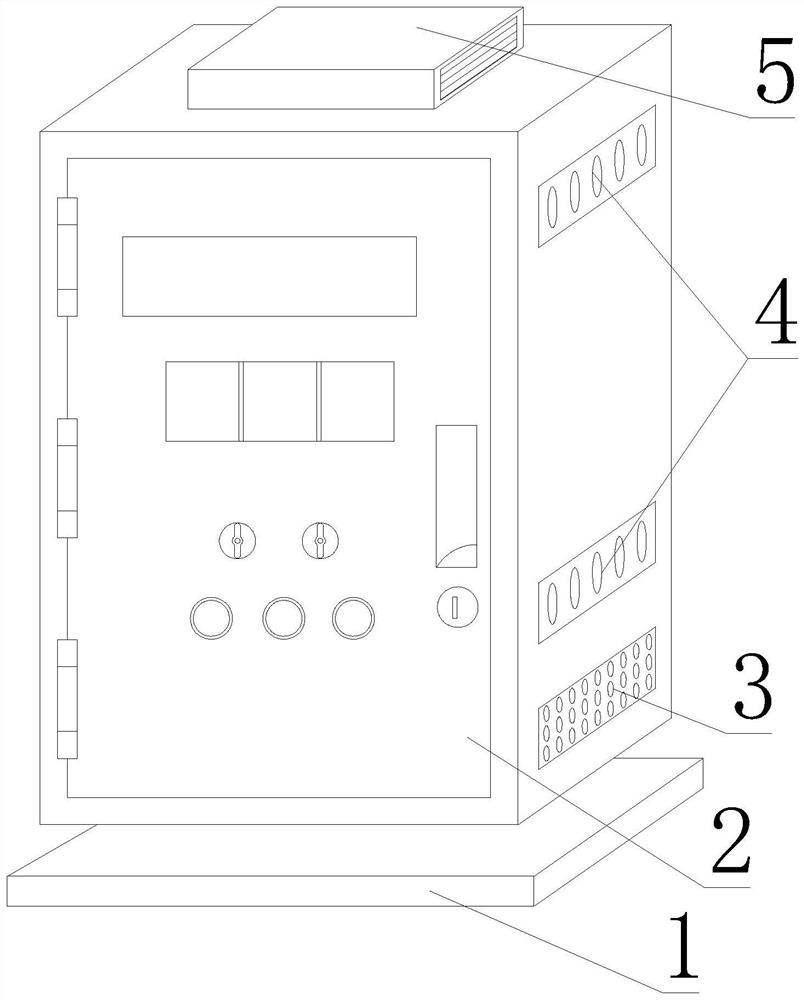

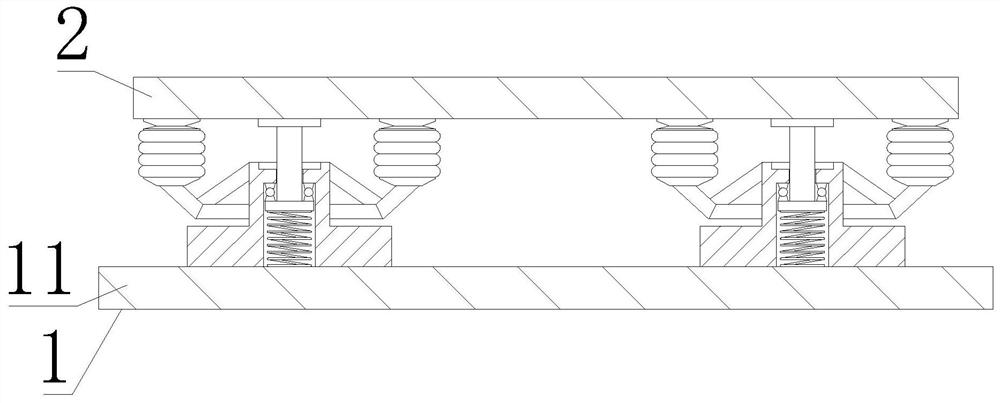

[0044] First, as Figure 1-5As shown, the present invention provides a power supply control device for a mobile communication base station, comprising a power supply control device main body 2, a base 1 is fixedly installed at the bottom of the power supply control device main body 2, and inlets are opened at the bottoms of the left and right sides of the power supply control device main body 2. Air port 3, threading plates 4 are fixedly installed on the left and right sides of the power supply control device main body 2, and a radiator 5 is fixedly installed on the top of the power supply control device main body 2. The base 1 includes an I-shaped guide post 18, and the top of the I-shaped guide post 18 is installed. It is fixedly installed with the bottom of the main body 2 of the power supply control device, the outer wall of the I-shaped guide post 18 is movably sleeved with a guide sleeve support 12, the bottom of the guide sleeve support 12 is fixedly installed with a sup...

Embodiment 2

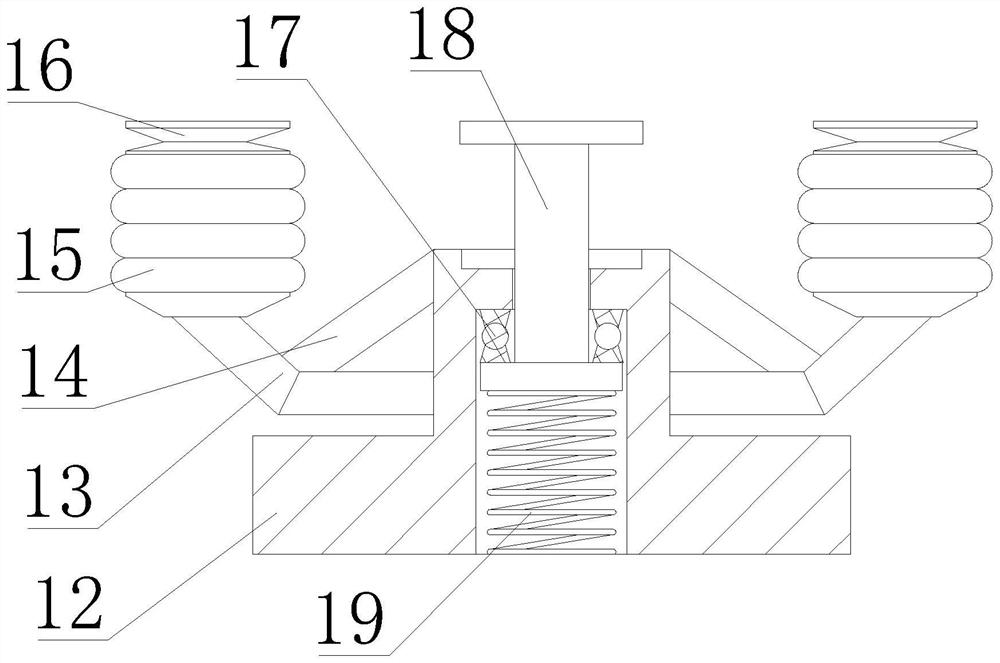

[0047] like Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a support bracket 13 is fixedly connected to the middle of the outer wall of the guide sleeve support 12, and a reinforcement plate 14 is fixedly connected to the front of the support bracket 13. , the top of the reinforcing plate 14 is fixedly installed with an annular buffer spring washer 15, the top of the annular buffer spring washer 15 is fixedly installed with an I-shaped tray 16, and the bottom of the annular airbag cushion 17 and the bottom of the inner cavity of the guide sleeve support 12 are overlapped with The spring 19, the outer wall of the I-shaped guide post 18 and the top of the inner wall of the guide sleeve support 12 are movably sleeved with an annular airbag cushion 17.

[0048] In this embodiment, the bottom of the main body 2 of the power supply control device is supported by the action of the annular buffer spring 15 and the s...

Embodiment 3

[0050] like Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, threaded sleeves 43 are fixedly sleeved on both sides of the front of the lower clamping plate 42, and the inner wall of the threaded sleeve 43 is located between the upper clamping plate 41 and the upper clamping plate 41. The front side of the lower clamping plate 42 is threadedly connected with a threaded rod 44, the rubber wire sleeve 47 includes an upper clamping sleeve 471, the outer wall of the upper clamping sleeve 471 is clamped with the bottom of the upper clamping plate 41, and the bottom of the upper clamping sleeve 471 is clamped with a lower clamping sleeve. Sleeve 473, the upper ferrule 471 and the inner wall of the lower ferrule 473 are fixedly connected with anti-skid protruding strips 472.

[0051] In this embodiment, through the action of the threaded sleeve 43 and the threaded rod 44, the connection between the upper clamping plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com