Ink jet recording apparatus and method

A technology of inkjet recording and recording head, which is applied in the direction of measuring device, measuring device, printing device, etc., can solve the problem of reducing the responsiveness of the carriage, and achieve the effect of suppressing damage and low frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

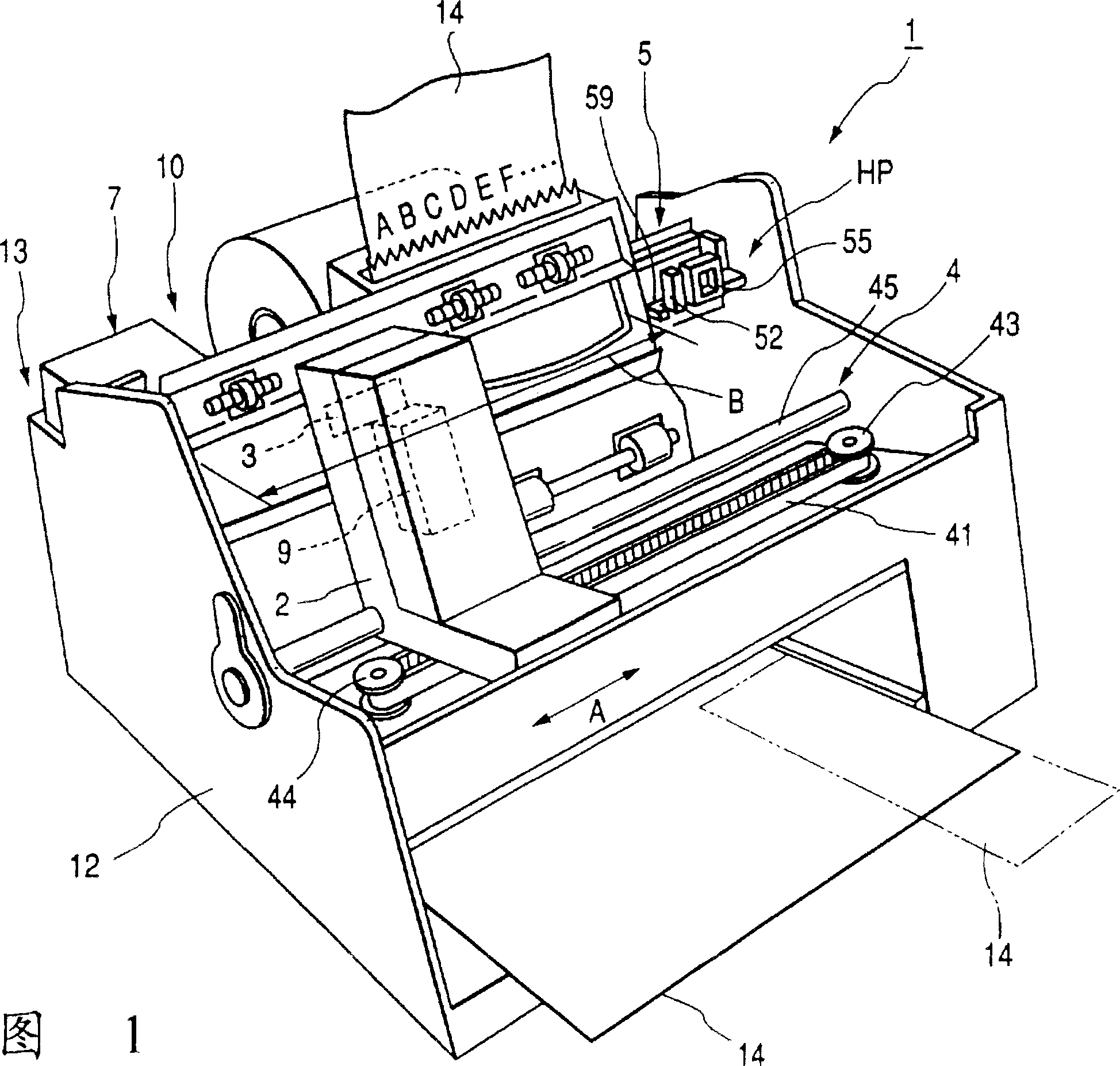

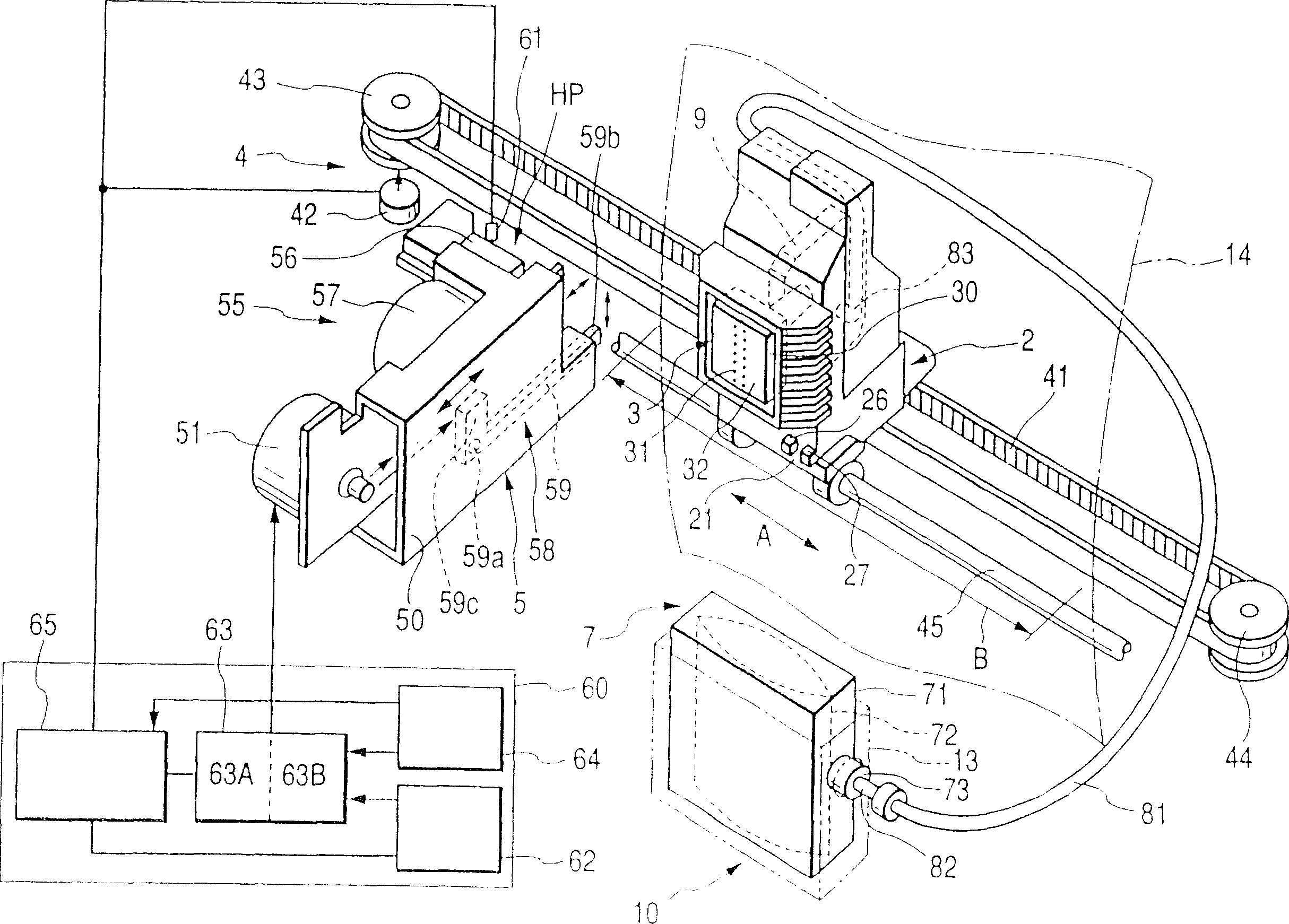

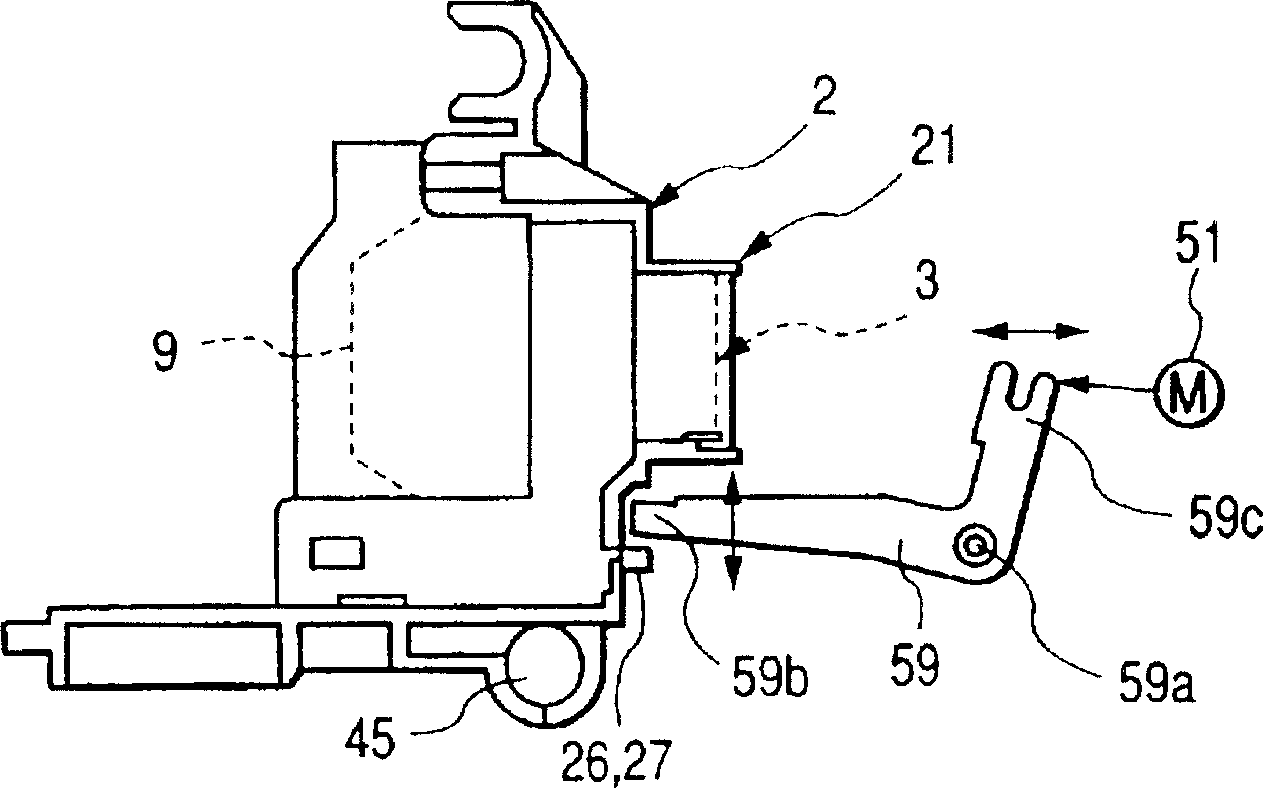

[0034] The inkjet recording apparatus 1 has a recording head 3 for ejecting ink droplets, and a carriage 2 carrying the recording head 3, a carriage drive mechanism 4 that drives the carriage 2 in the scanning direction shown by arrow A, and An ink supply mechanism 10 for supplying ink to the recording head 3 . The recording head 3 has a nozzle forming surface 32 on which a plurality of nozzles 31 for ejecting ink droplets are provided. The nozzle forming surface 32 is exposed outside the rectangular opening 30 on the carriage 2 .

[0035] Such as figure 2 As shown, the carriage drive mechanism 4 includes a guide rod 45 , a timing belt 41 stretched between the driving pulley 43 and the driven pulley 44 , and a carriage motor 42 for rotationally driving the driving pulley 43 . The lower side of the carriage 2 is slidably supported on the guide rod 45 and connected with the speed regulating belt 41 . When the timing belt 41 is driven by the carriage motor 42 , the carriage 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com