Production process and equipment for multiple-cavity glass bottle and jar

A technology of glass bottles and glass gobs, applied in glass manufacturing equipment, glass pressing, glass molding, etc., can solve the problems of dazzling parting lines and affecting product quality, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

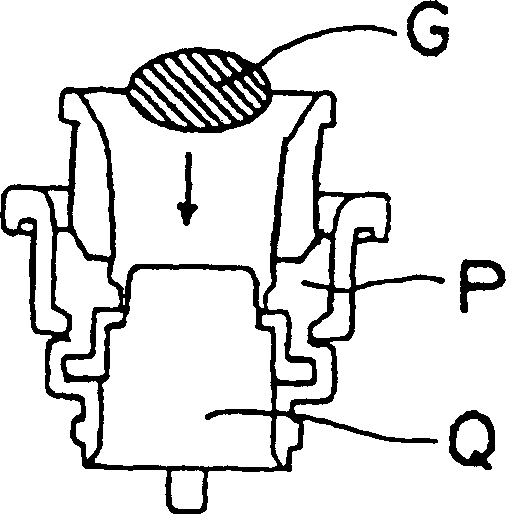

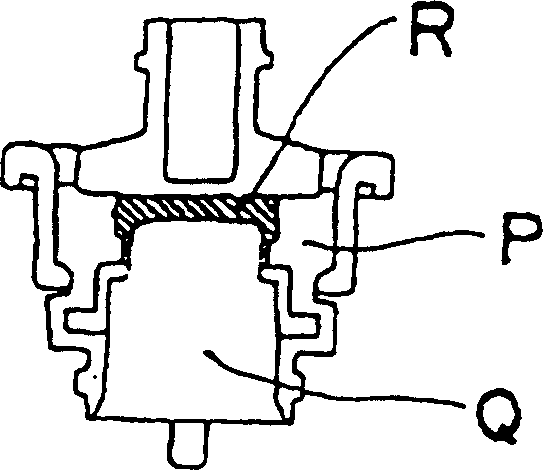

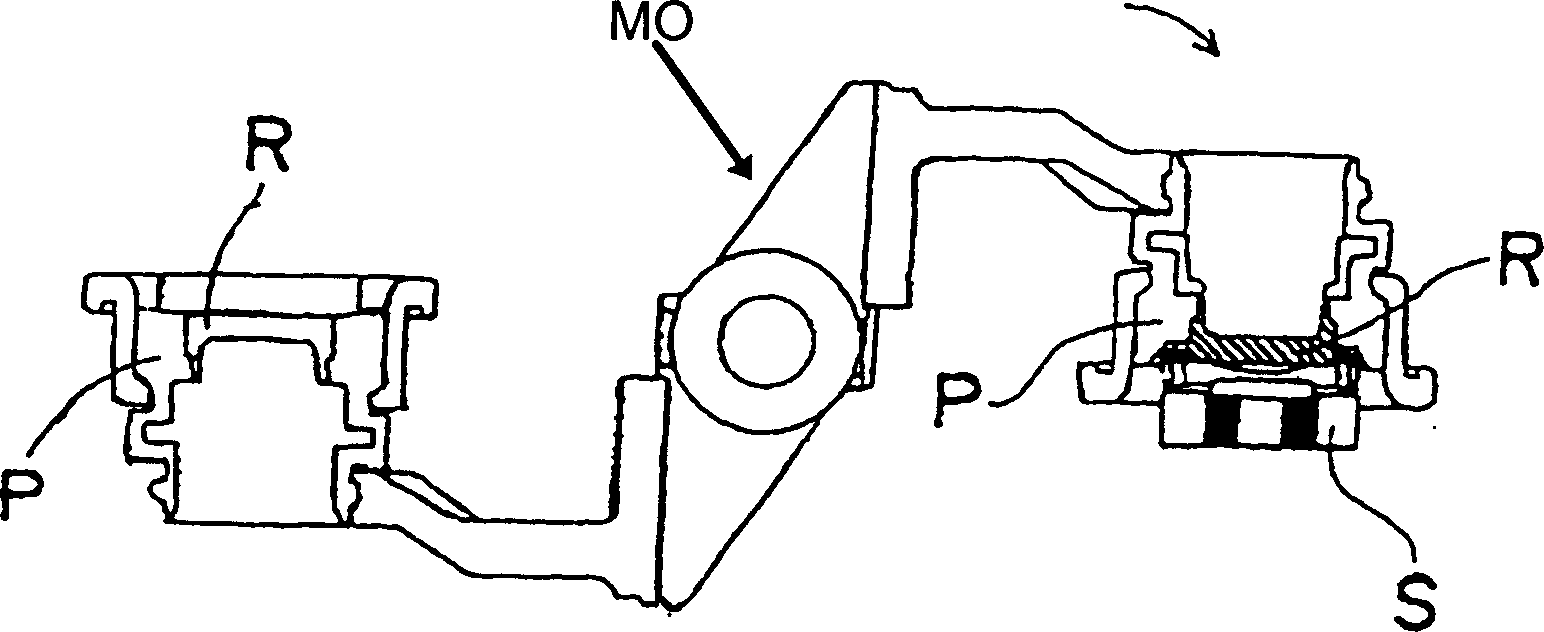

[0018] In the present invention, compared with the traditional bottle making method bottle making equipment, the most important difference is the structure of the mould. Therefore, see first figure 2 To explain the structure of the mold in the bottle making equipment of the present invention. like figure 2 Shown, on the whole, mold structure of the present invention and traditional Image 6 The structural molds are basically similar, and the difference lies in the structure of the die. As mentioned earlier, in the traditional Image 6 In the mold of the structure, it includes the mouth mold P0 and the initial mold H0, the mouth mold P0 forms the bottleneck of the glass bottle, and the initial mold H0 forms the bottle body of the glass bottle. However, in the present invention, the traditional mouth mold and the initial mold are integrated to form a novel mouth mold P, which contains a bottle mouth shape PU1 and a bottle body shape PU2. Same as the traditional structure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com