Absorption refrigerator

A technology for absorption and refrigerators, which is applied in the direction of adsorption machines, refrigerators, refrigeration components, etc., and can solve problems such as the inability to accurately determine the optimal circulation rate of absorption liquids in the heat exchanger stages of multiple absorption refrigerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

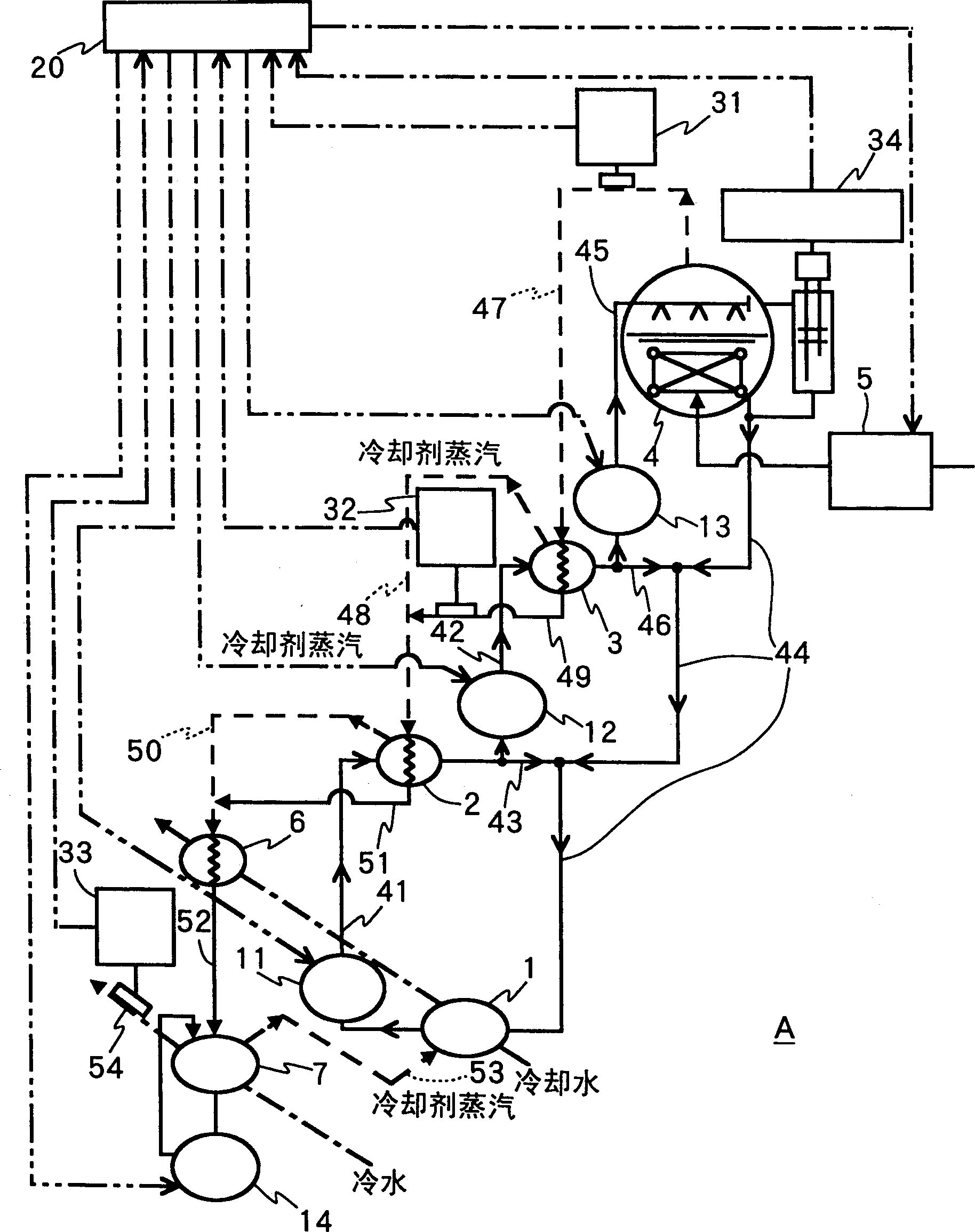

Embodiment 1

[0042] figure 1 It is a schematic diagram of the absorption refrigerator according to the first embodiment of the present invention. The absorption refrigerator A in the figure is a reverse cycle absorption refrigerator with triple absorption, including: absorber 1, which allows the absorption liquid whose main component is lithium bromide to absorb water and other coolants; low temperature heat exchanger 2 , It heats the diluted absorption liquid whose concentration is reduced due to the absorption of the coolant in the absorber 1, and evaporates part of the coolant from the diluted absorption liquid, thereby obtaining a medium-concentration absorption liquid from the concentration of the diluted absorption liquid; The medium-temperature heat exchanger 3 heats the medium-concentration absorption liquid obtained by the low-temperature heat exchanger 2, and further vaporizes part of the coolant, so that the absorption liquid is further concentrated, thereby obtaining a high-concen...

Embodiment 2

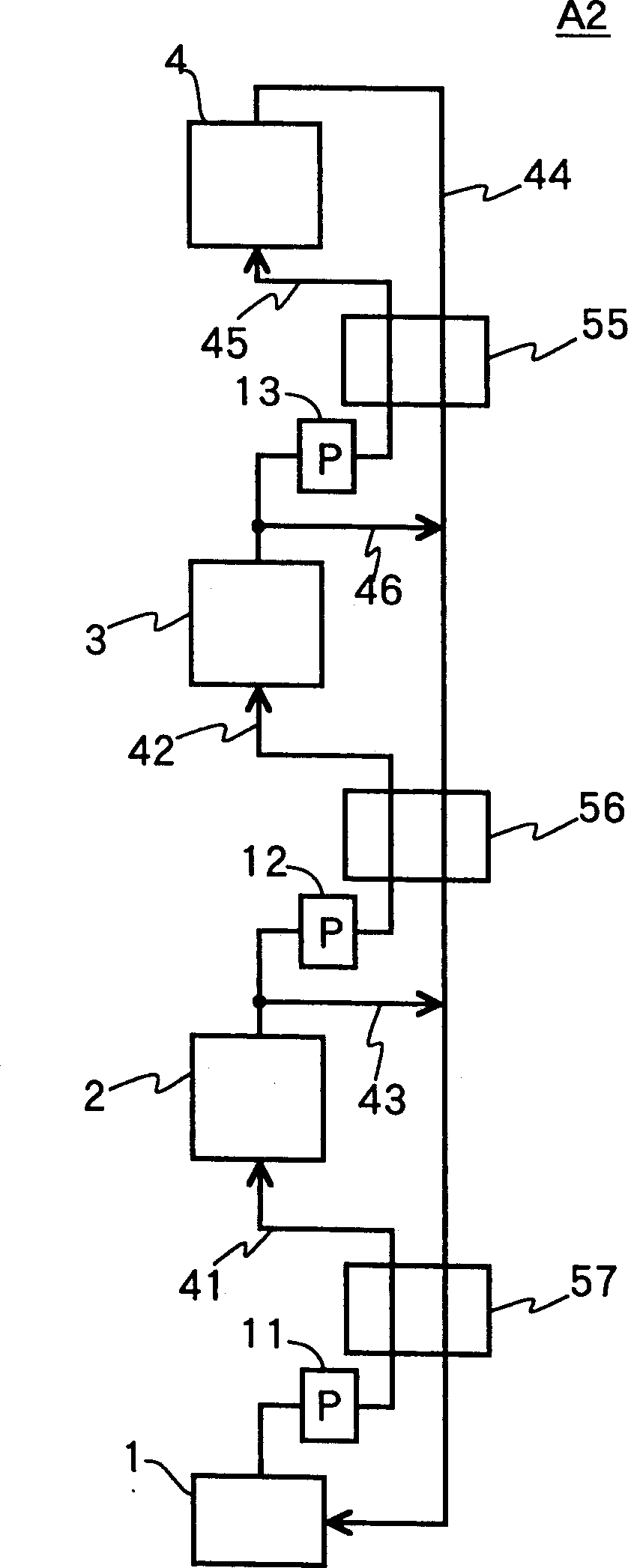

[0079] figure 2 This shows the absorption refrigerator in the second embodiment of the present invention. The absorption refrigerator A2 in Example 2 has improved the heat exchange system of the absorption refrigerator A in Example 1, and the rest of the structure is the same as the former.

[0080] Specifically, the absorption refrigerator A2 includes: a high-temperature heat exchanger 55 for transferring the ultra-high-concentration absorption liquid back from the high-temperature heat exchanger 4 to the absorber 1 through the return pipe 44 and passing through the high-concentration liquid feed pipe 45 for heat exchange between the high-concentration absorption liquid fed to the high-temperature heat exchanger 4; a medium-temperature heat exchanger 56 for heat exchange between the following two aspects of the liquid, on the one hand, after the above-mentioned heat exchange The mixed liquid of the ultra-high-concentration absorption liquid and the high-concentration absorption ...

Embodiment 3

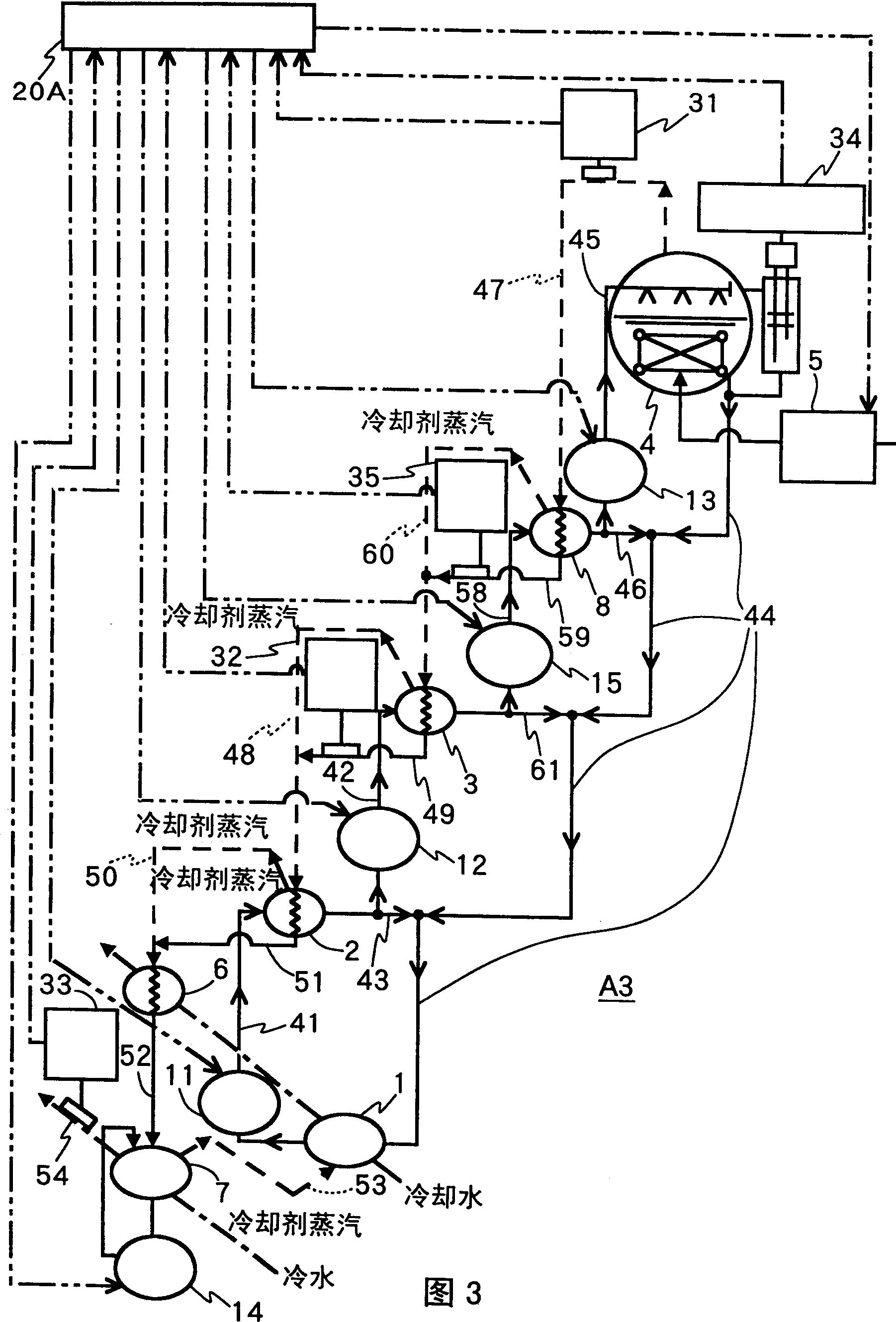

[0083] Fig. 3 shows the principle structure of the absorption refrigerator in the third embodiment of the present invention. The absorption refrigerator A3 in the third embodiment is also improved on the basis of the absorption refrigerator A in embodiment 1. In the path from the medium temperature heat exchanger 3 to the high temperature heat exchanger 4 to feed the absorption liquid A second medium-temperature heat exchanger 8 is added, which can be called an absorption refrigerator with four-stage heat exchange effect.

[0084] That is to say, on the basis of the absorption refrigerator A in the embodiment 1, the second medium temperature heat exchanger 8 is added to the structure of the absorption refrigerator A3, which uses the coolant vaporized by the high temperature heat exchanger 4 The steam heats and concentrates the absorption liquid (hereinafter referred to as the second medium-concentration absorption liquid) heated and concentrated by the medium-temperature heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com