Floating ship type water collecting trough with perforations

A technology of sump and pontoon, which is applied to the feeding/discharging device of settling tank, etc., can solve the problems of complex structure, heavy weight and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

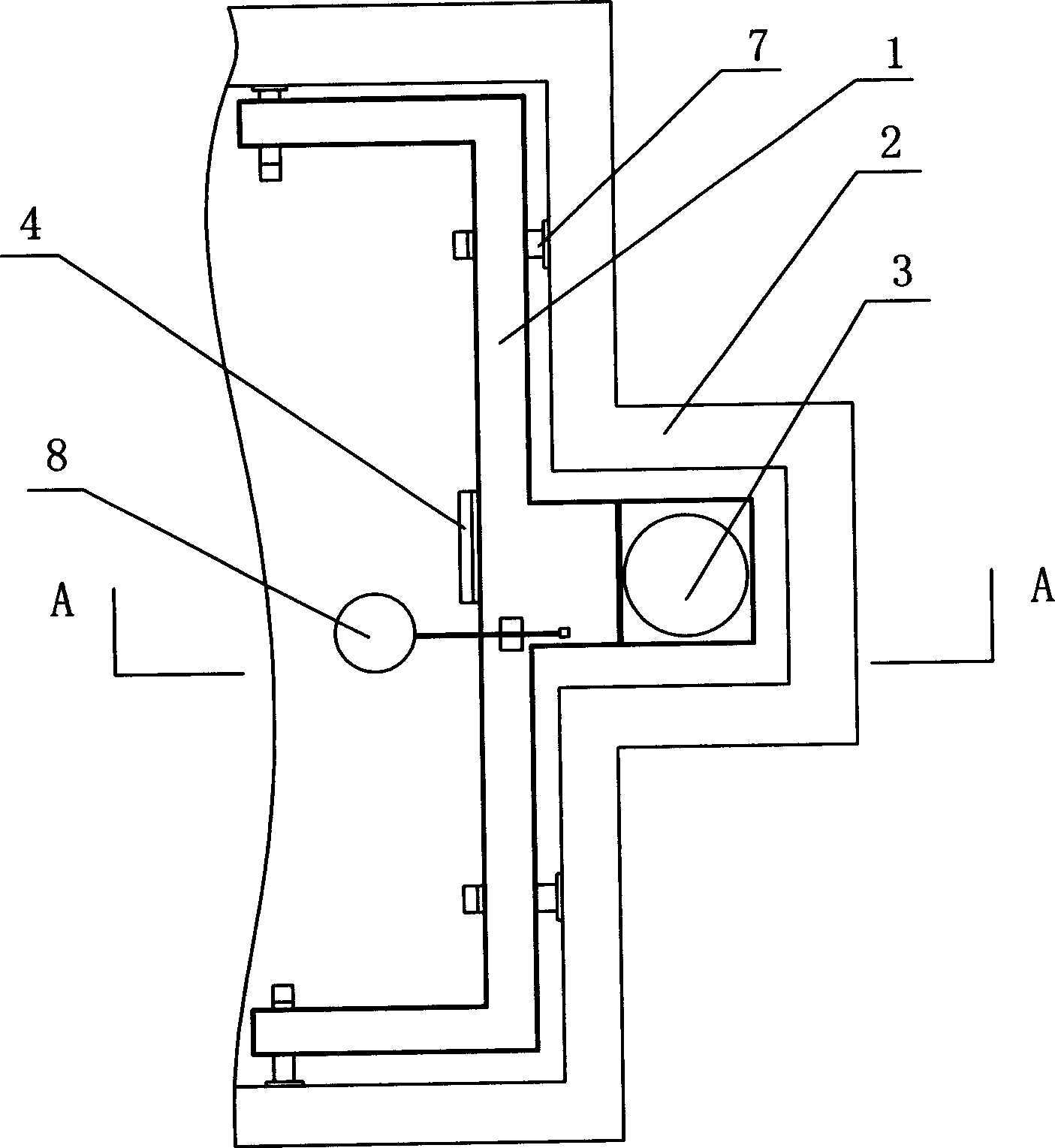

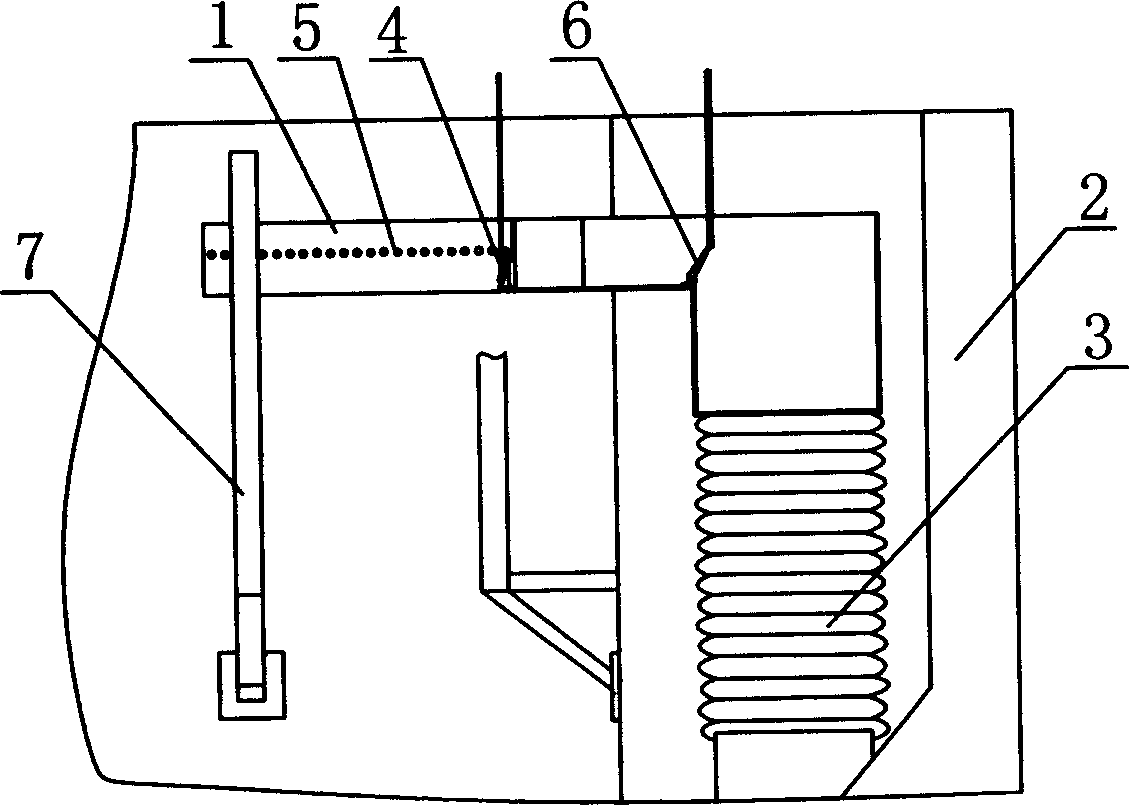

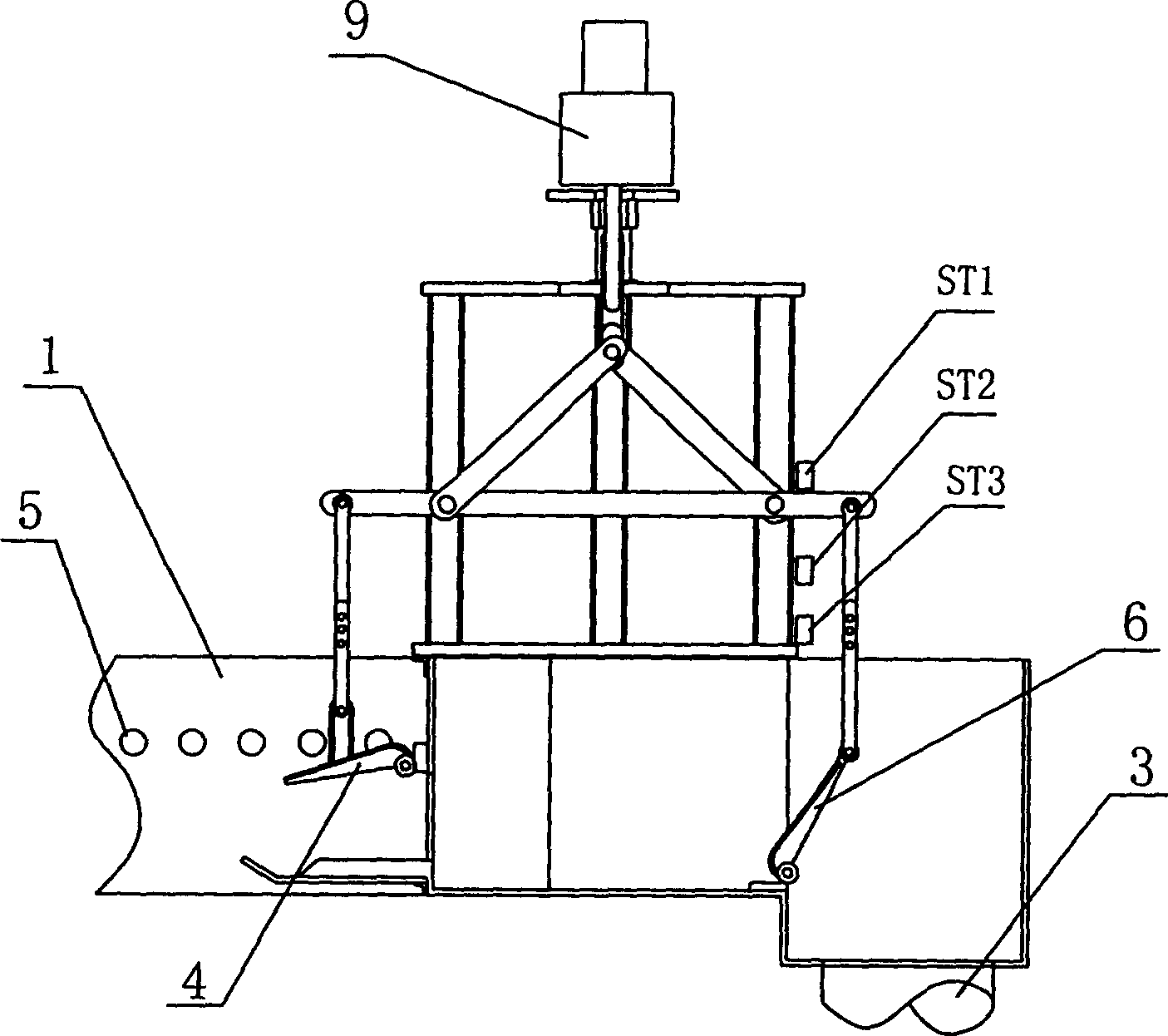

[0060] Embodiment one: see attached figure 1 To attach Figure 11 As shown, a floating boat-type perforated water collection tank includes a tank body 1 with a water collection hole 5 and a water outlet pipe 3. The water outlet pipe 3 communicates with the tank body 1. The top surface of the tank body 1 is open, and the water collection hole 5 Distributed on both sides of the tank body 1, a rotating weir plate adjustment structure is provided at the connection between the tank body 1 and the outlet pipe 3, the rotating shaft is located at the bottom of the tank body, and a water filling valve 4 that can be controlled to open and close is provided at the bottom of the tank body 1. The water filling valve 4 is a rotary valve, and the rotating shaft is located on the upper part of the valve; it also includes a control device that can drive the water level adjustment structure and the water filling valve. The control device makes the water collection tank have three states. In th...

Embodiment 2

[0080] Embodiment two: see attached Figure 12 As shown, a floating boat-type perforated water collection tank has the same basic structure as the embodiment, wherein the water level adjustment structure between the tank body and the outlet pipe adopts a lift-type weir plate adjustment structure, and the water retaining height of the weir plate increases when it rises. When descending, the water retaining height of the weir plate decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com