Method and device for charging valve-control type lead-acid accumulator

A lead-acid battery, battery voltage technology, applied in battery circuit devices, secondary battery charging/discharging, circuit devices, etc., can solve problems such as battery unusable

Inactive Publication Date: 2004-12-08

GS YUASA INT LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in VRLA batteries, if the water is consumed, the electrolyte dries out prematurely, and the battery cannot be used since the battery contains only a very small amount of electrolyte

Therefore, when the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

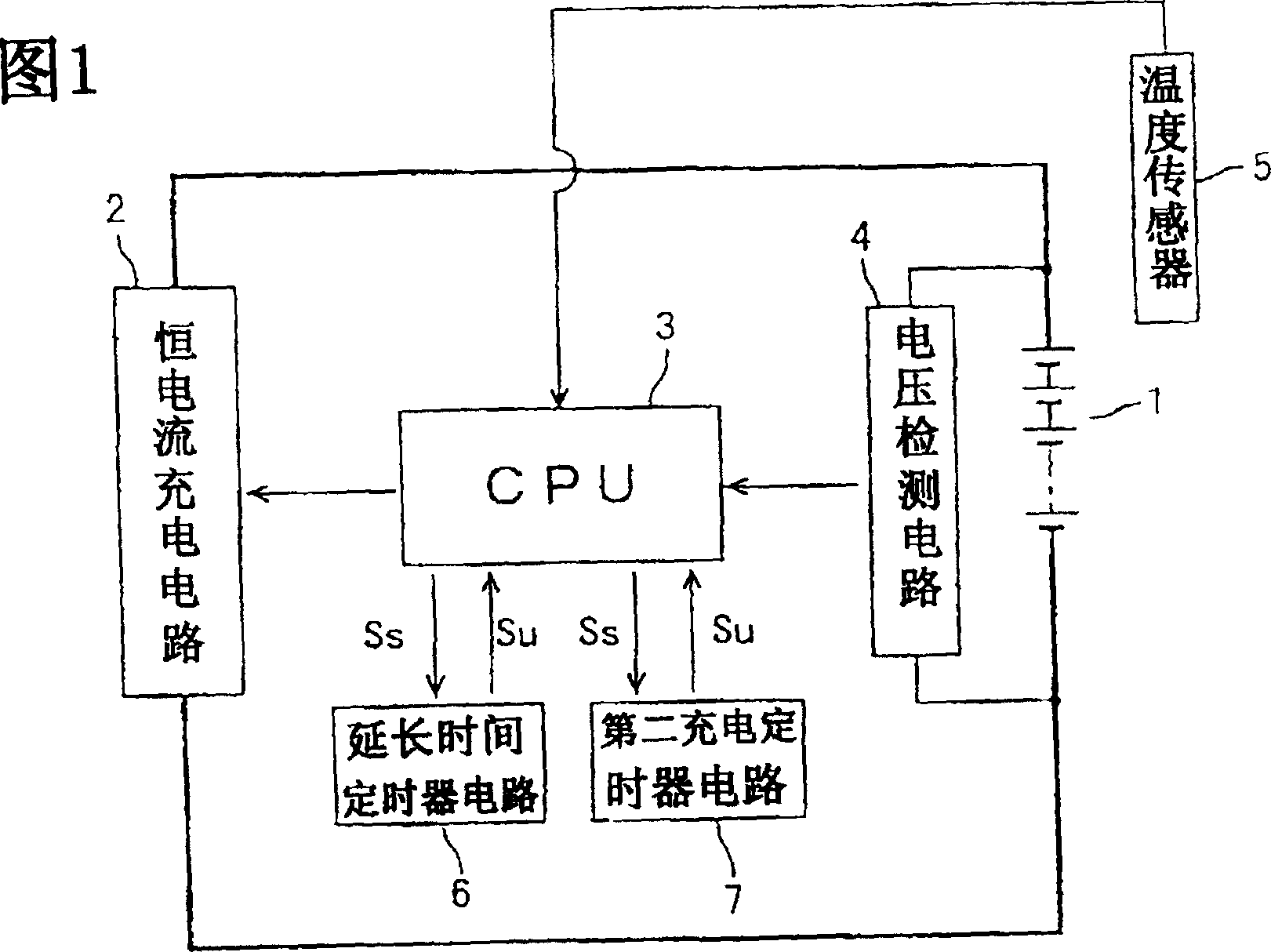

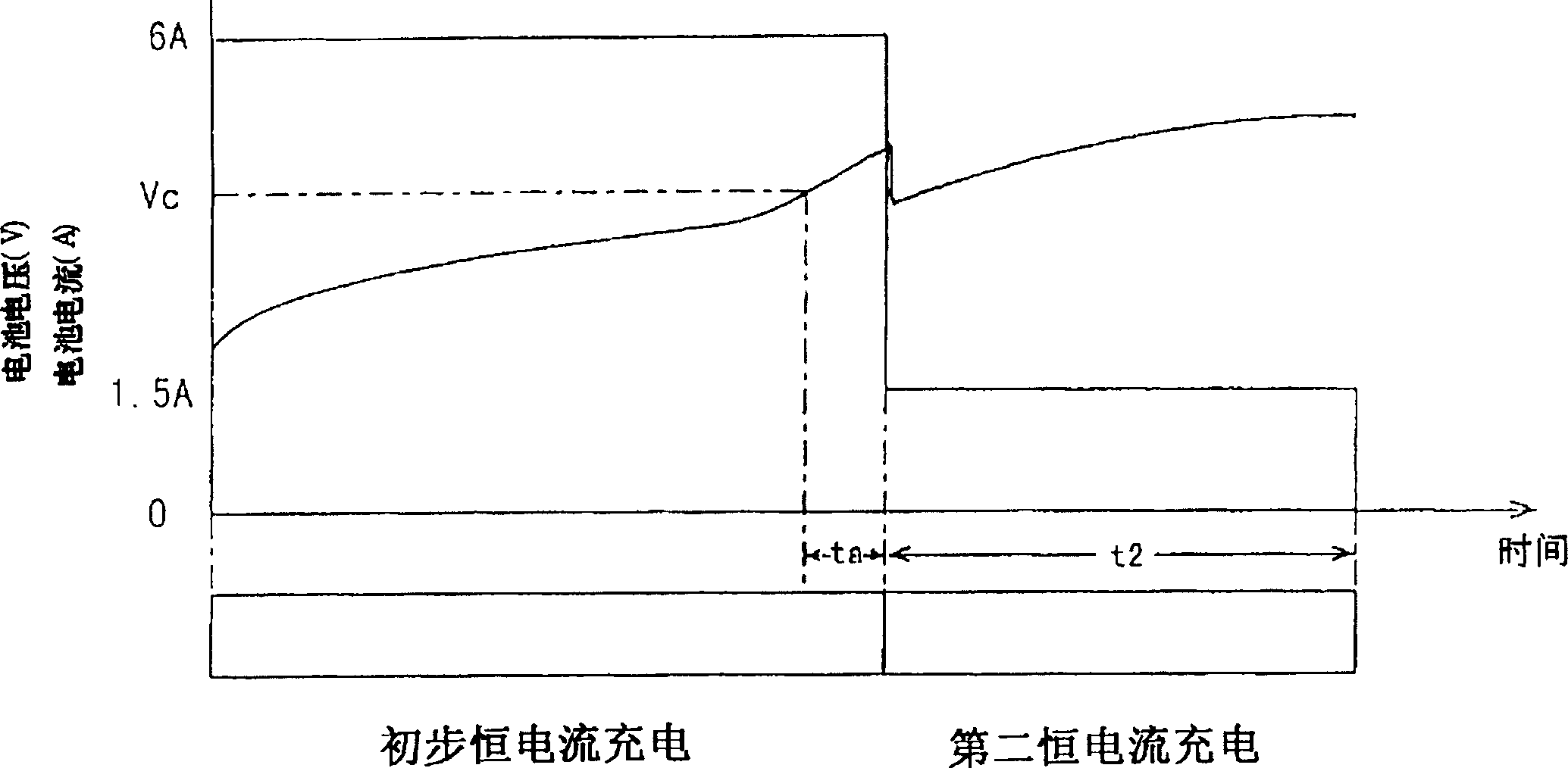

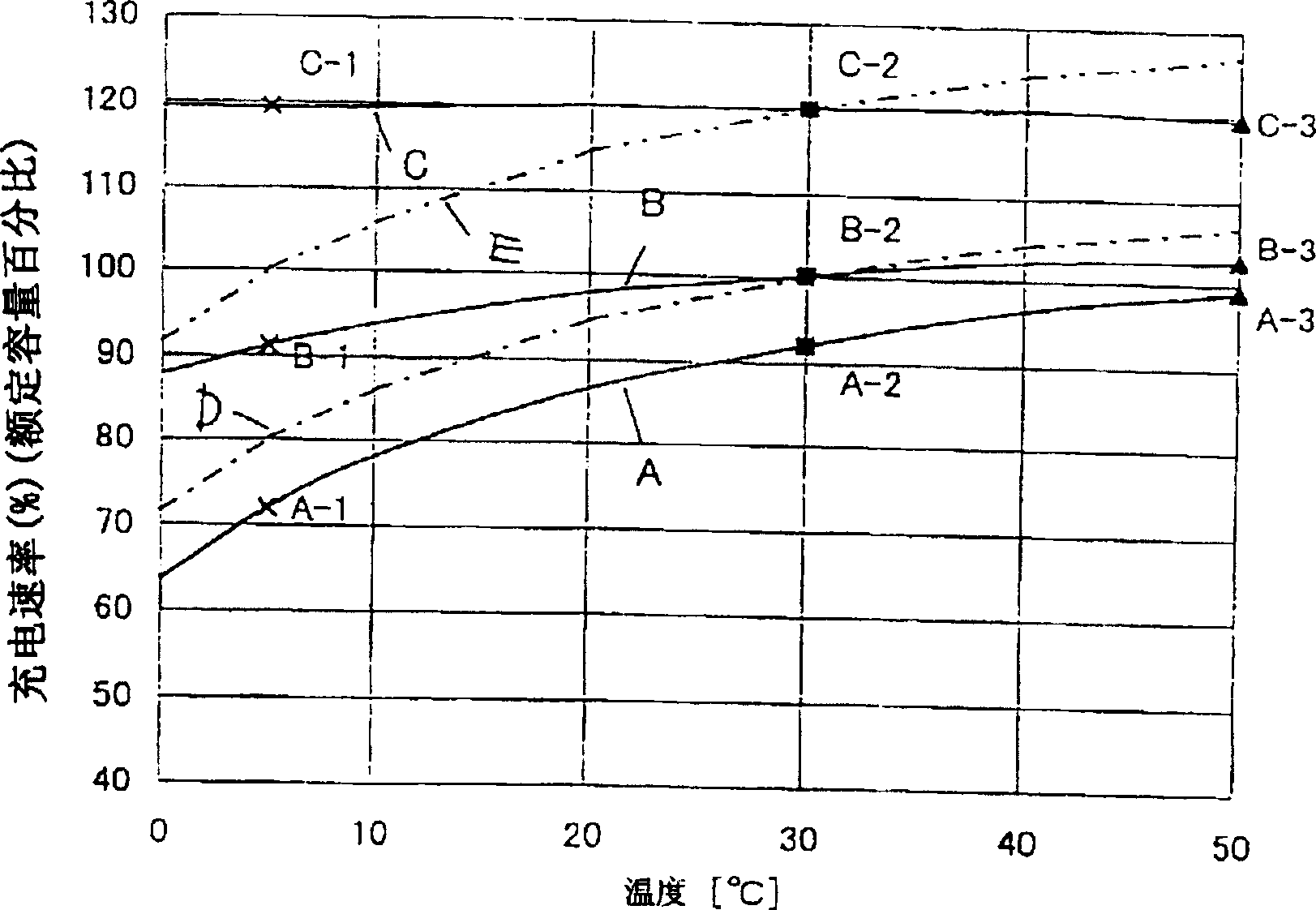

A charging method and a charging apparatus which can be used particularly for charging a valve-regulated lead acid battery using a Pb-Sb alloy grid as a positive electrode grid. Primary constant-current charging is performed with a predetermined current value. The primary constant-current charging is further continued for an extension time t after the battery voltage reaches a change-over voltage Vc. After the extension time has passed, the charging is changed over to secondary constant-current charging using a current value smaller than that of the primary constant-current charging. The extension time for continuing the primary constant-current charging is preferably set so as to be shorter as the battery temperature is higher. Also a secondary charging time for executing the secondary constant-current charging is preferably set so as to be shorter when the battery temperature is higher.

Description

technical field [0001] The present invention relates to a method and apparatus for charging a valve-regulated lead-acid battery capable of simultaneously reducing the charging current in steps. Background technique [0002] For charging lead-acid batteries for recycling purposes in electric vehicles, passenger cars, golf carts, etc., short-term two-stage constant current charging is possible. [0003] The two-stage constant current charging method is to charge the lead-acid battery with a large current before the voltage of the lead-acid battery reaches the predetermined switching voltage, and when the voltage reaches the switching voltage, the charging is switched to low current charging, and the low current charging lasts for a predetermined time until the charging rate reaches A predetermined value such as a discharge rate of 120%. [0004] In this charging method, in order to shorten the charging time, it is necessary to perform a preliminary charging cycle with a large...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02J7/00

CPCH02J7/0091H02J7/007194

Inventor 根本圣治

Owner GS YUASA INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com