Semiconductor laser V shaped groove fixed optical fiber coaxial device

A fiber coaxial and laser technology, applied in the field of optical fiber communication, can solve problems such as affecting a wide range of applications and reducing the cost of semiconductor laser coaxial devices, and achieve the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

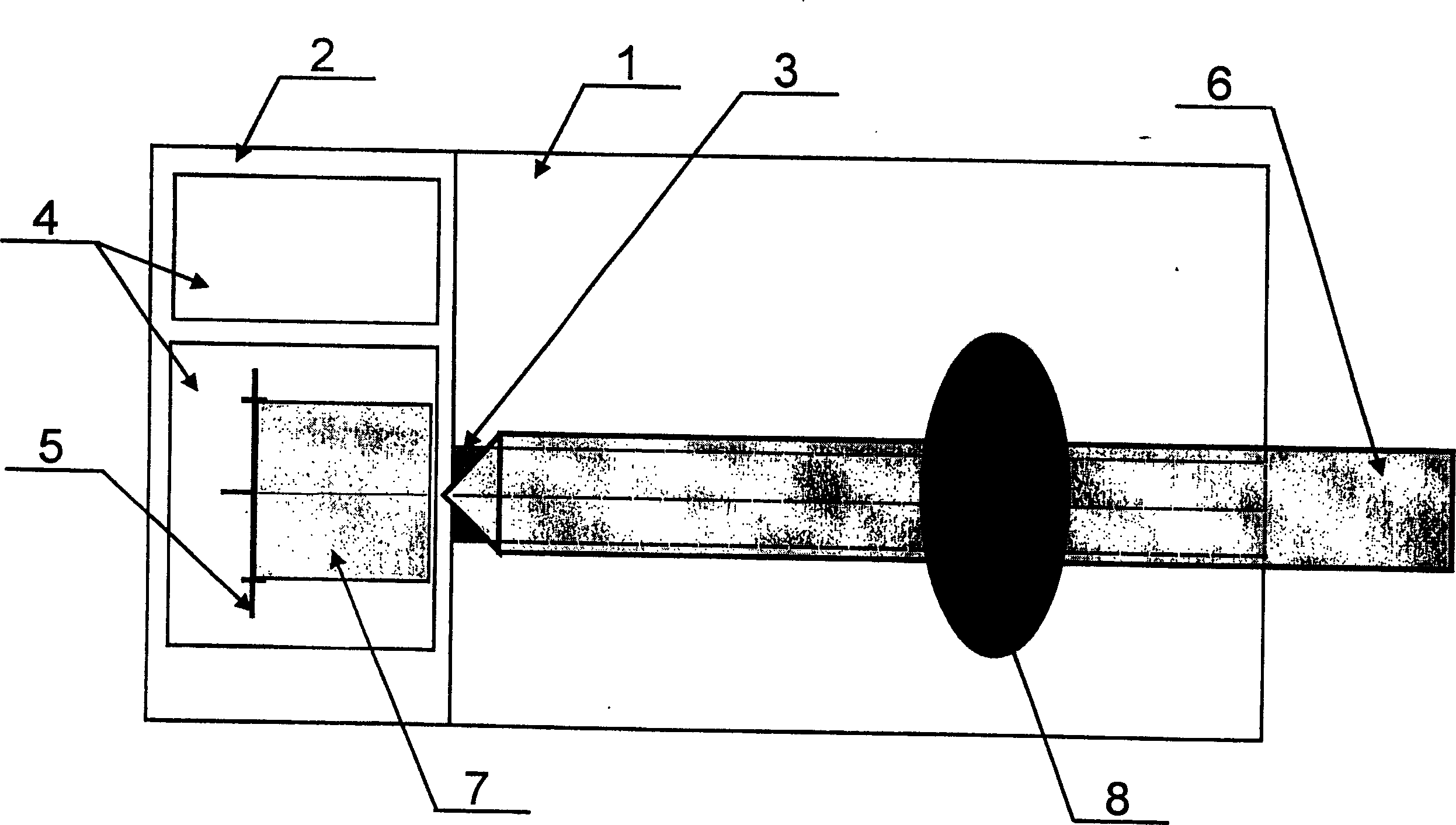

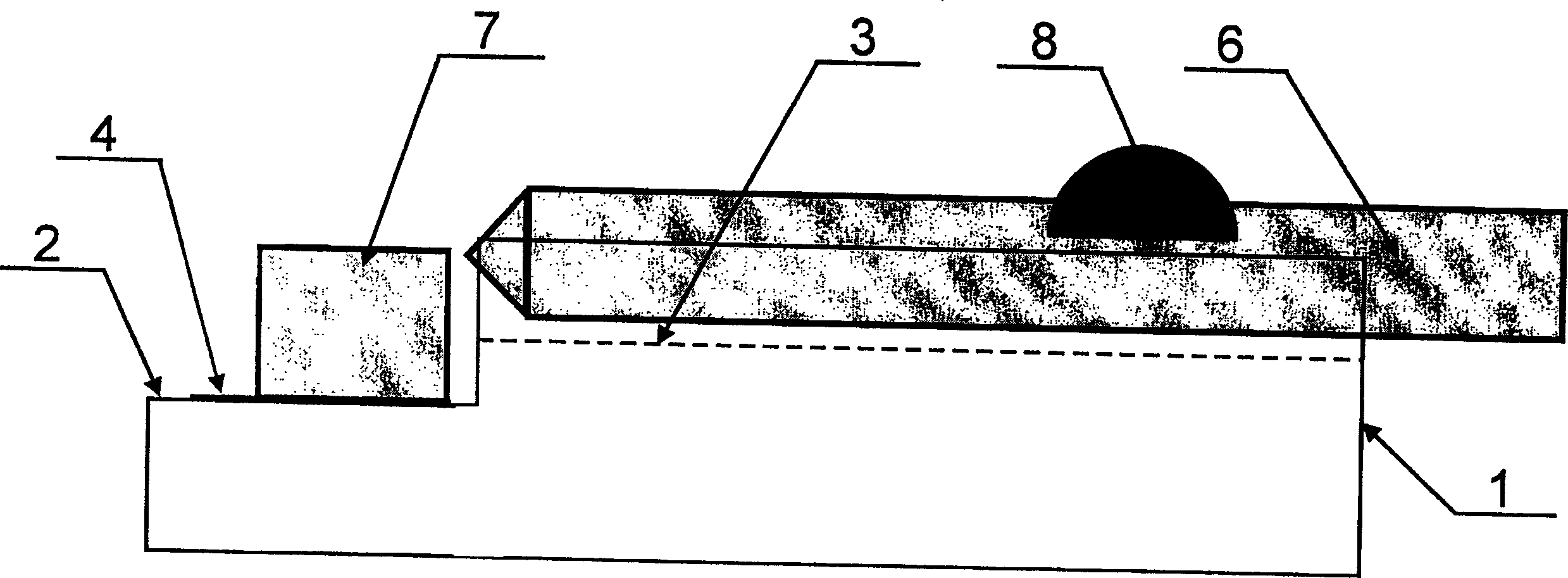

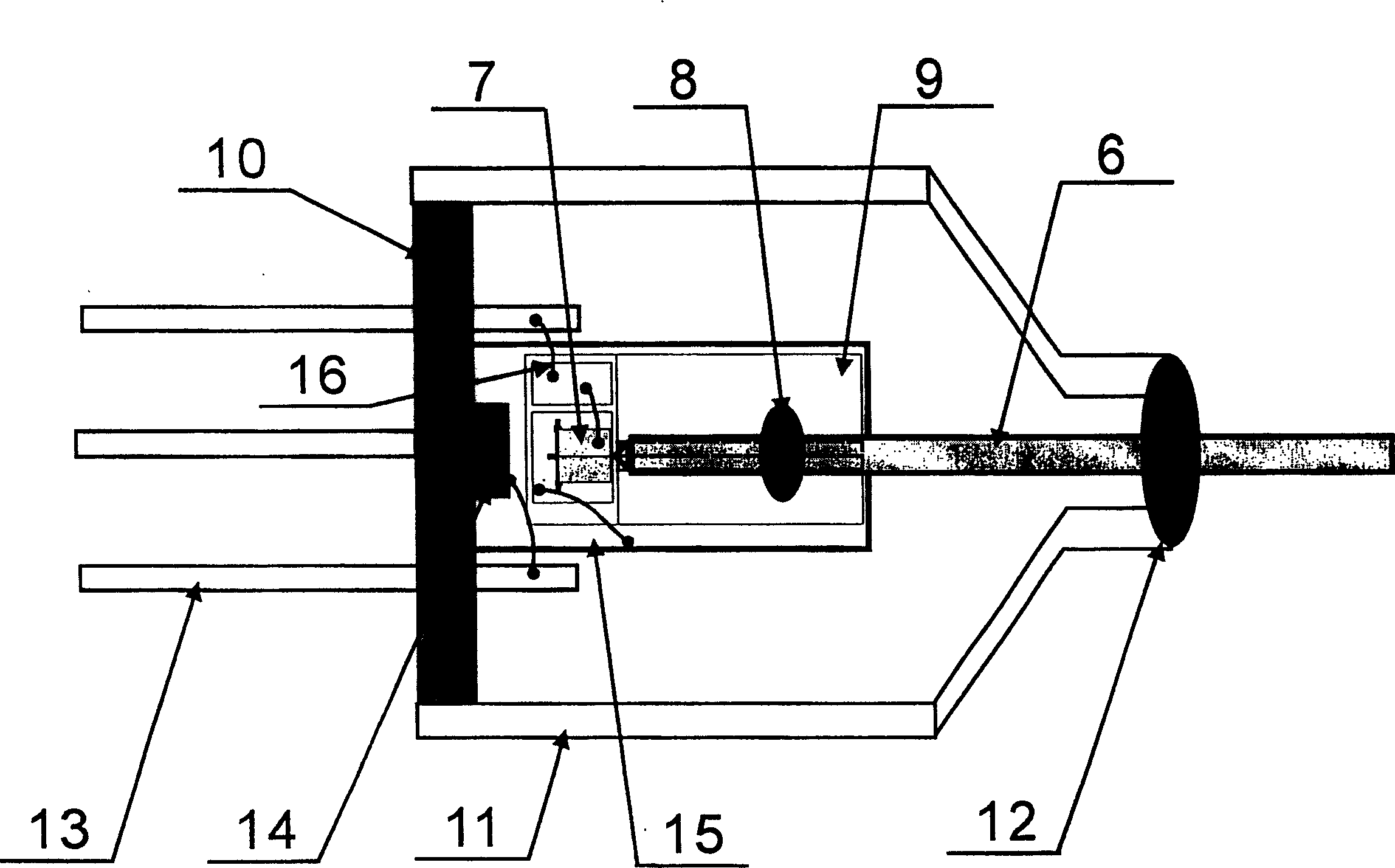

[0022] see figure 1 and figure 2 ,exist figure 1 and figure 2 In the embodiment, the high mesa 1 of the heat sink, the low mesa 2 of the heat sink and the V-shaped groove 3 are respectively made on the silicon heat sink 9 by combining dry etching and wet etching micromachining techniques. Then use microelectronic technology to make planar electrodes 4 and alignment marks 5 on the lower mesa 2 of the heat sink, and make a back gold layer on the back of the silicon heat sink 9 . In this process, it is easy to ensure strict alignment with the centerlines of the V-shaped groove 3 and the alignment mark 5 by utilizing the precision of the micromachining technology and the microelectronics process. The waveguide and cleavage plane of the semiconductor laser 7 are aligned with the corresponding marks of the alignment mark 5 and welded on the plane electrode 4 . The head of the optical fiber 6 is shaped into a conical shape by grinding or high-temperature drawing, which can incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com