Semiconductor laser butterfly packaging device

A technology for packaging devices and lasers, applied in the field of semiconductor and optical fiber communication, can solve the problems of no light output, difficult coupling and alignment, low production efficiency, etc., achieve high-frequency characteristics and good temperature stability, reduce production costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

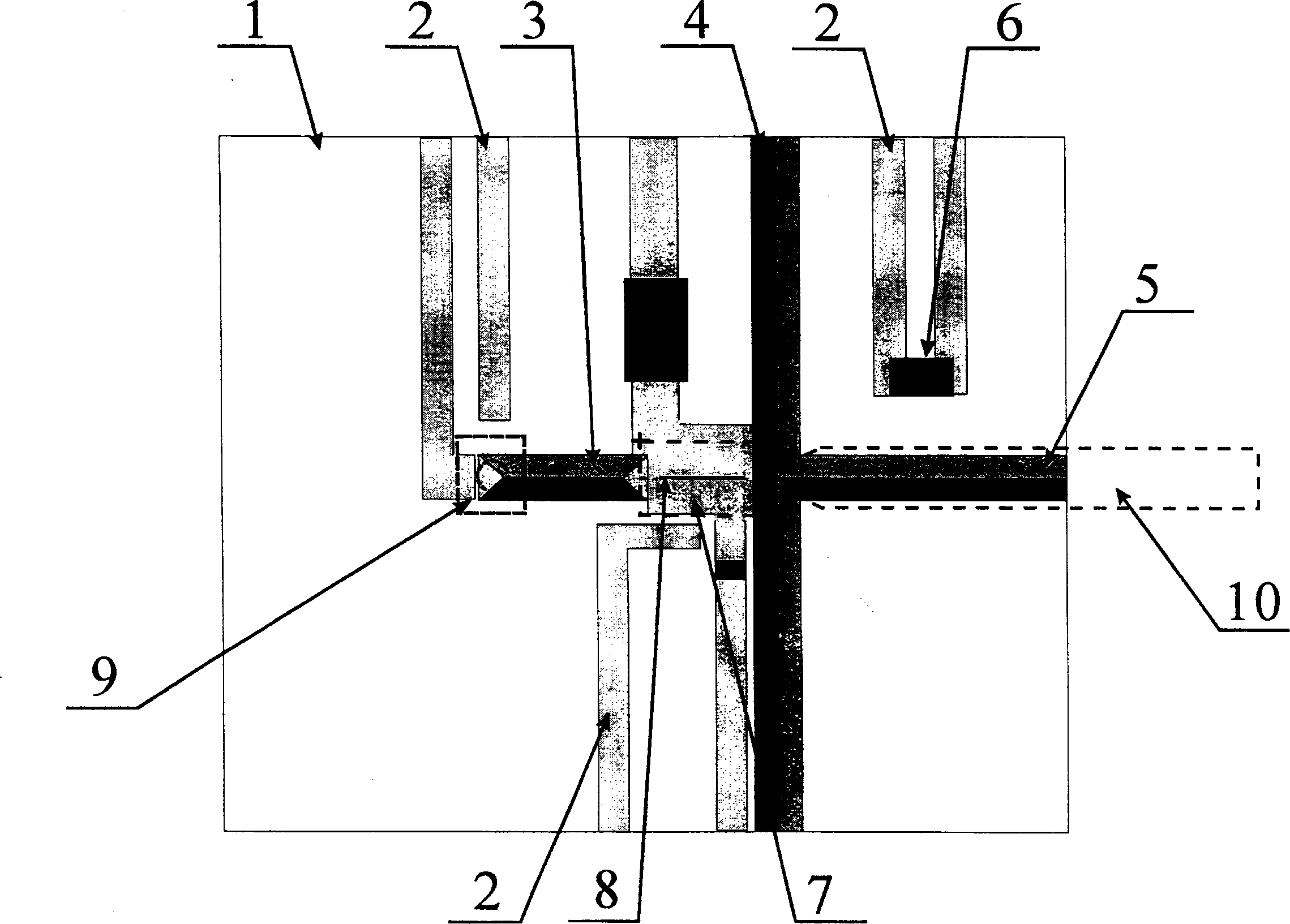

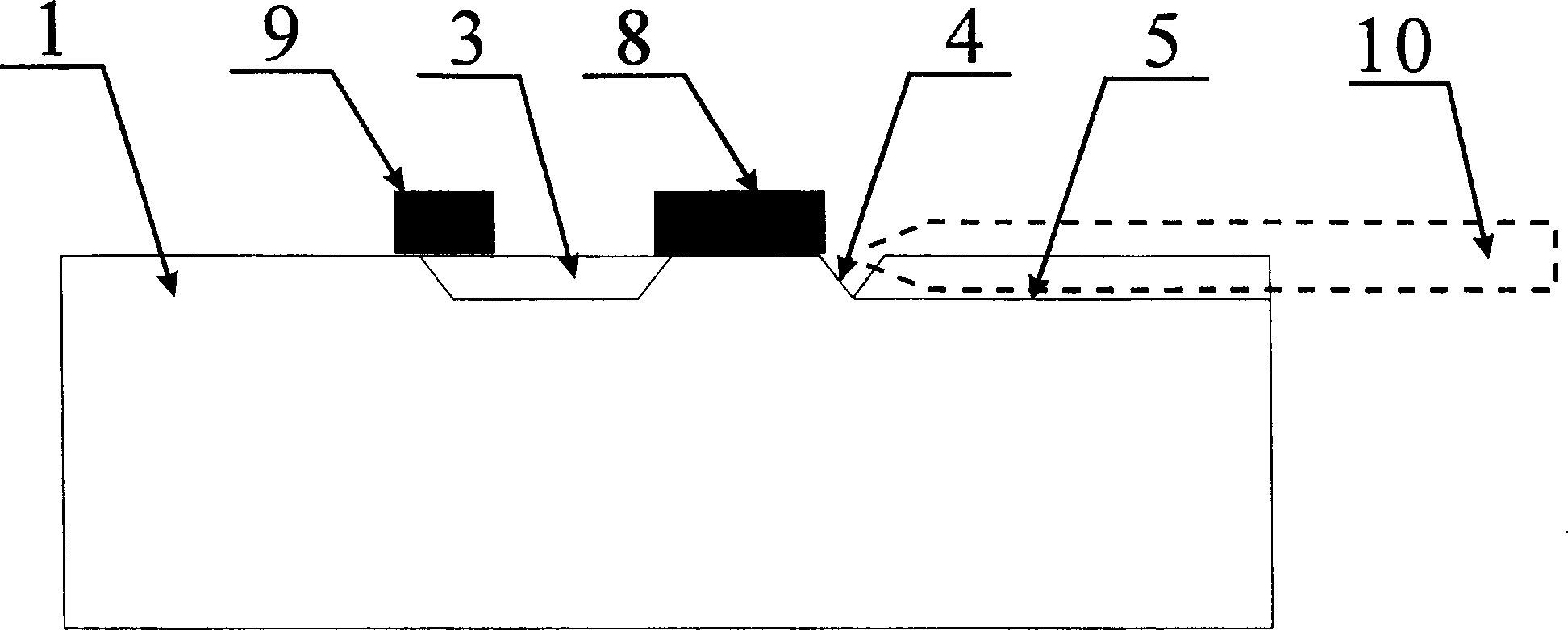

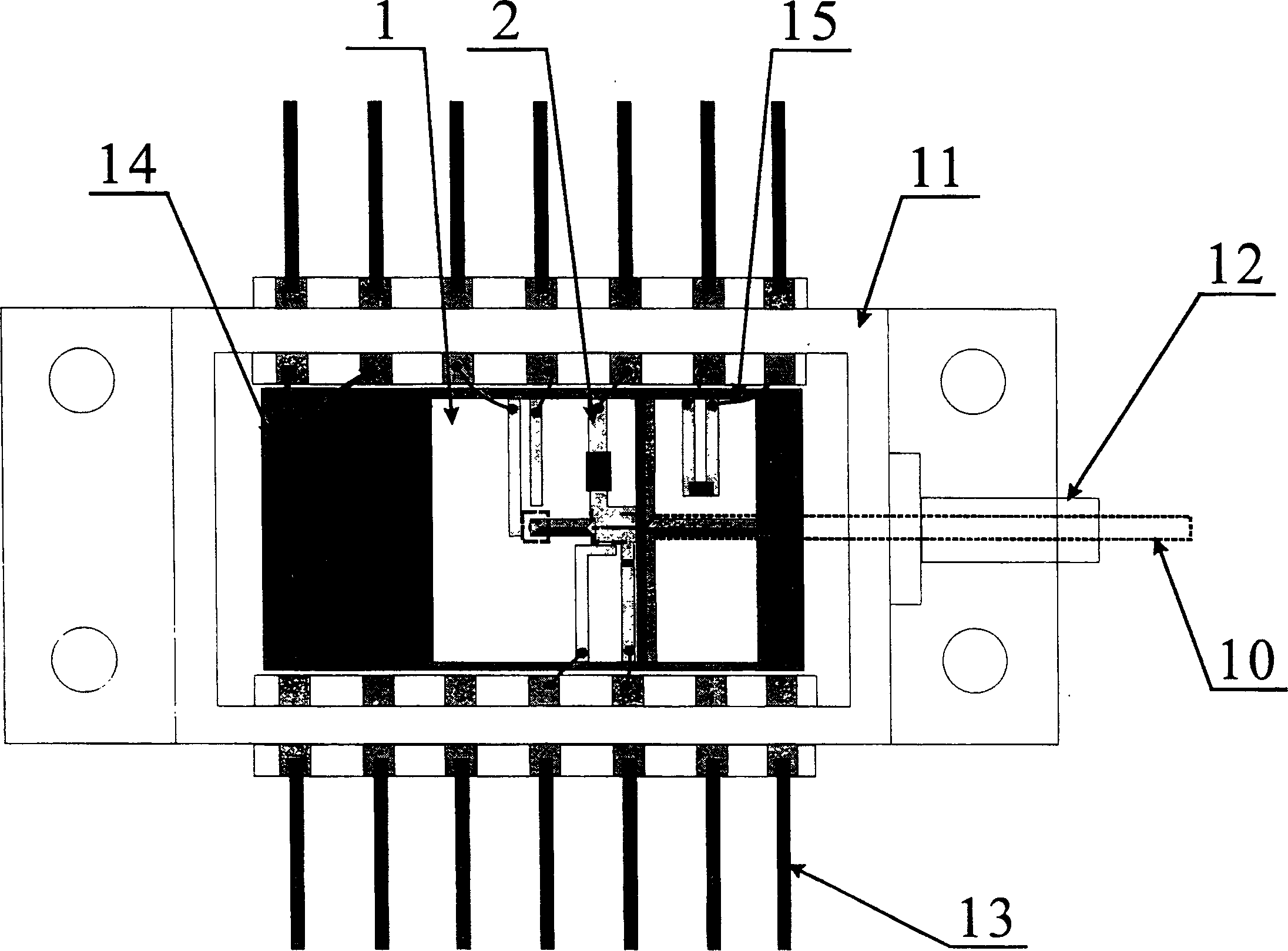

[0015] exist figure 1 and figure 2 In the embodiment, the V-groove 5 for the optical fiber, the V-groove 4 for the longitudinal direction and the V-groove 3 for the backlight are respectively made on the silicon heat sink 1 by wet etching micromachining technology. Then microelectronics technology is used to form a microwave microstrip circuit 2 and an alignment mark 8 on the silicon heat sink 1 , and to form a back gold layer on the back of the silicon heat sink 1 . During this process, it is easy to ensure strict alignment with the center line of the optical fiber V-groove 5 and the alignment mark 8 by utilizing the precision of the micro-machining technology and the micro-electronics process. Align the waveguide and cleavage plane of the semiconductor laser 7 with the corresponding mark of the alignment mark 8 by using an upside-down welding machine, and weld them on the microwave microstrip circuit 2 . The head of the optical fiber 10 is shaped into a conical shape by g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com