Adaptive coupled semiconductor laser butterfly sealing devices

A technology for packaging devices and semiconductors, which is applied in the direction of semiconductor lasers, laser components, lasers, etc., can solve the problems of no light output, difficulty in coupling alignment, low production efficiency, etc., and achieve high-frequency characteristics and temperature stability. Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

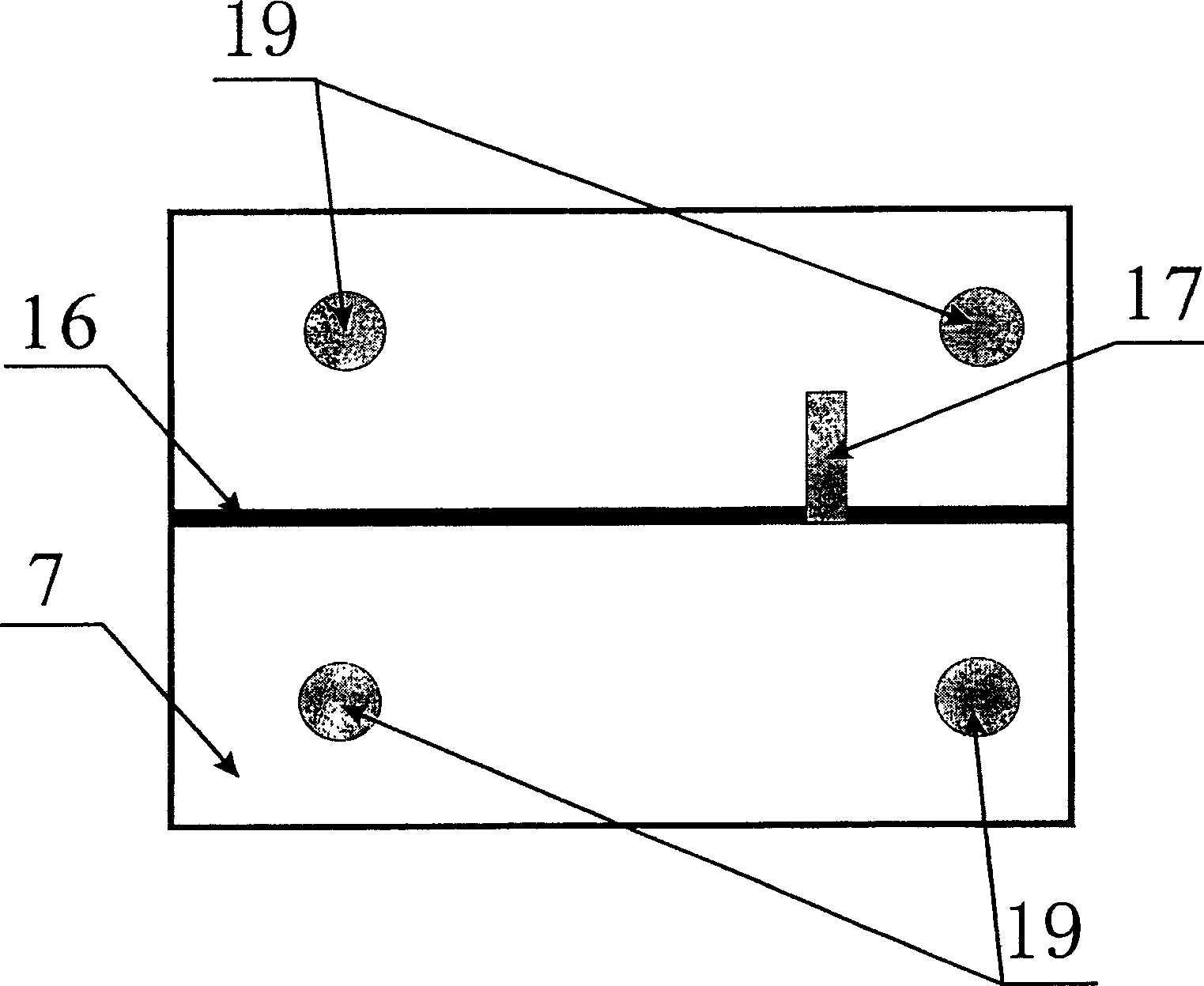

[0017] See figure 1 In the process of manufacturing the semiconductor laser 7, a high-frequency electrode 17 and four independent circular electrodes 19 that are strictly symmetric and uniformly distributed with the optical waveguide 16 as the symmetry axis are made on the electrode surface. The microelectronics process can ensure the independent circular The relative position of the shaped electrode 19 and the optical waveguide 16. Before the coupling operation of the semiconductor laser 7 is performed, solder balls are pre-fired on the four independent circular electrodes 19.

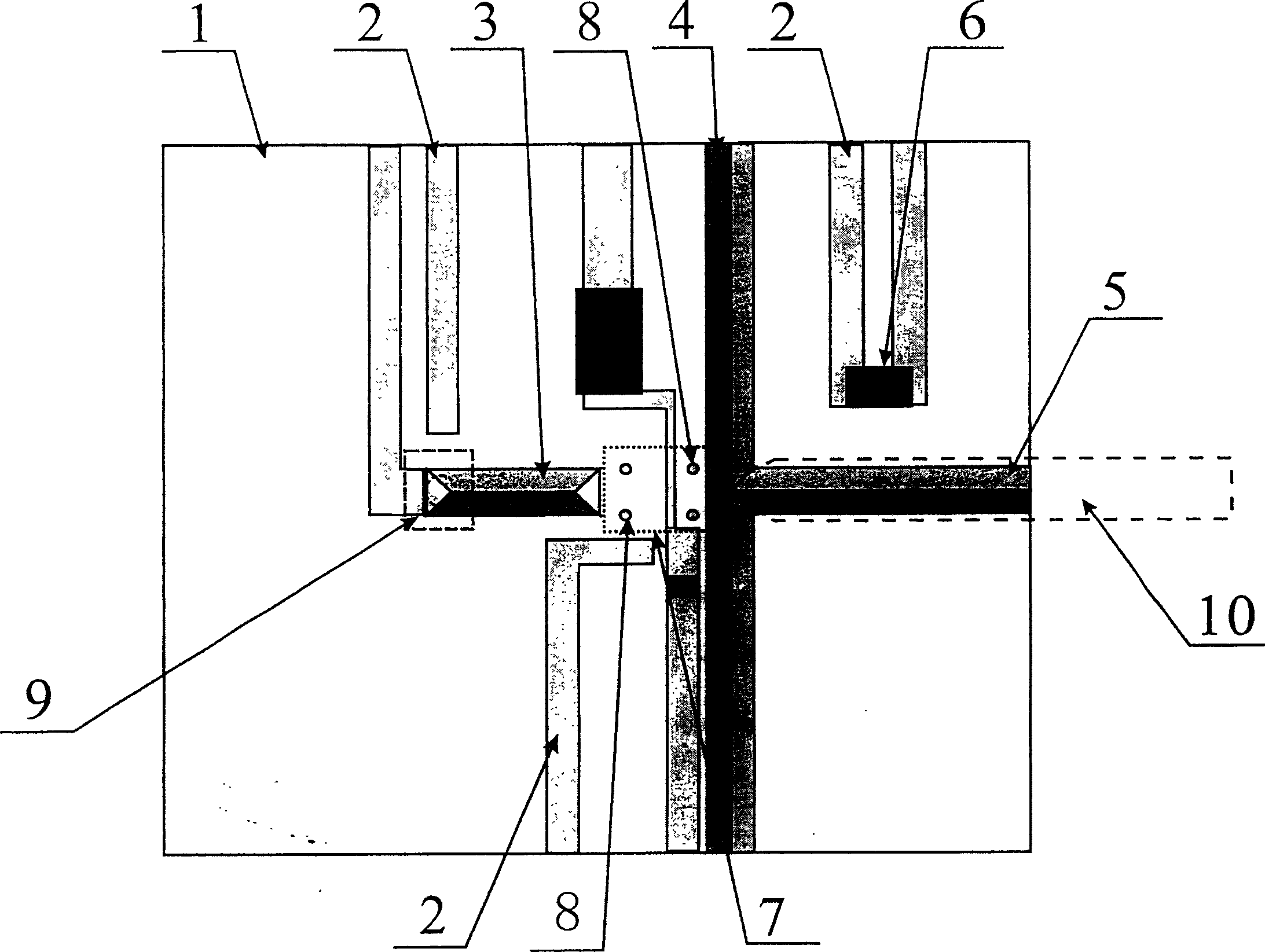

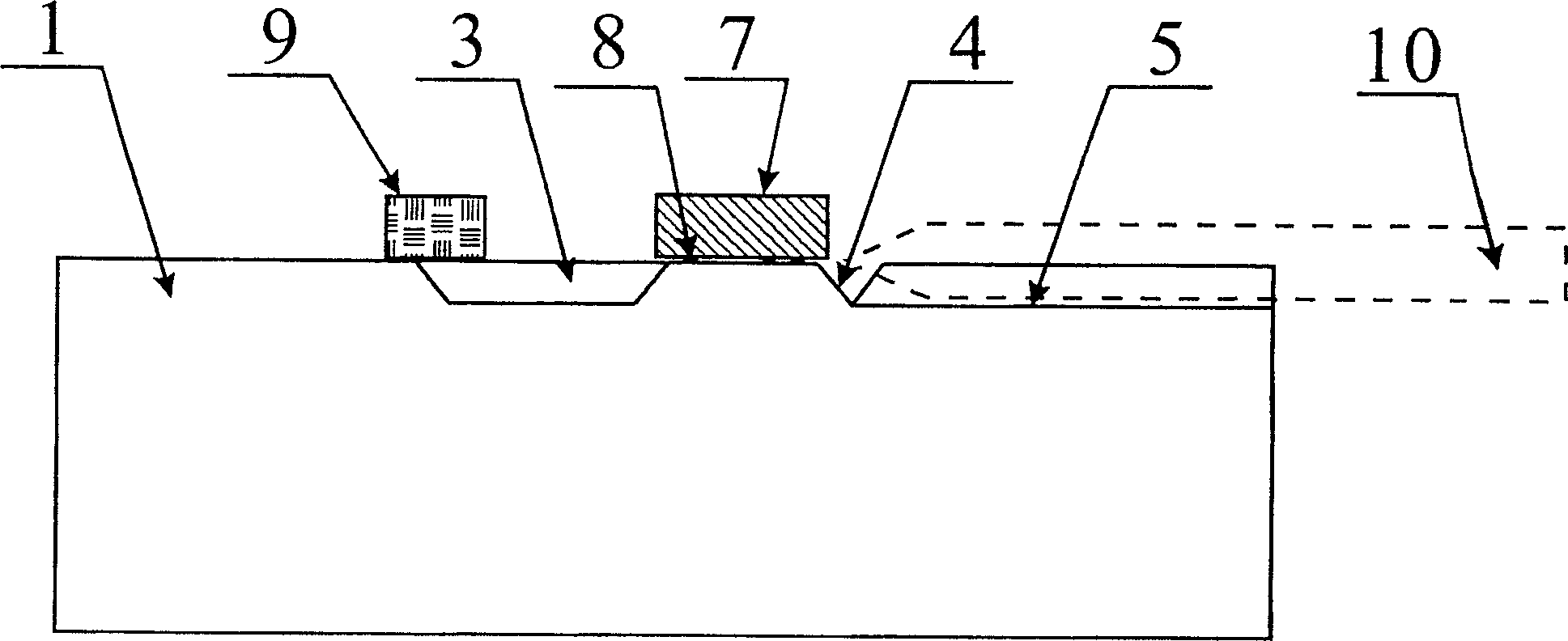

[0018] See figure 2 with image 3 , Using the micro-machining technology of wet etching to form an optical fiber V-groove 5, a longitudinal V-groove 4, and a backlight V-groove 3 on the silicon heat sink 1 respectively. Then, a microwave microstrip circuit 2 and four independent circular electrodes 8 are evenly distributed on the silicon heat sink 1 using a microelectronic process, and a back gold layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com