Method for producing and recovery film assembly control film holder or mounted lens

A technology for film cassettes and components, which is applied to film packaging, camera bodies, instruments, etc., can solve the problems of inability to identify, expensive identification systems, and increased number of processes, and achieves the effect of improving efficiency and tracking ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

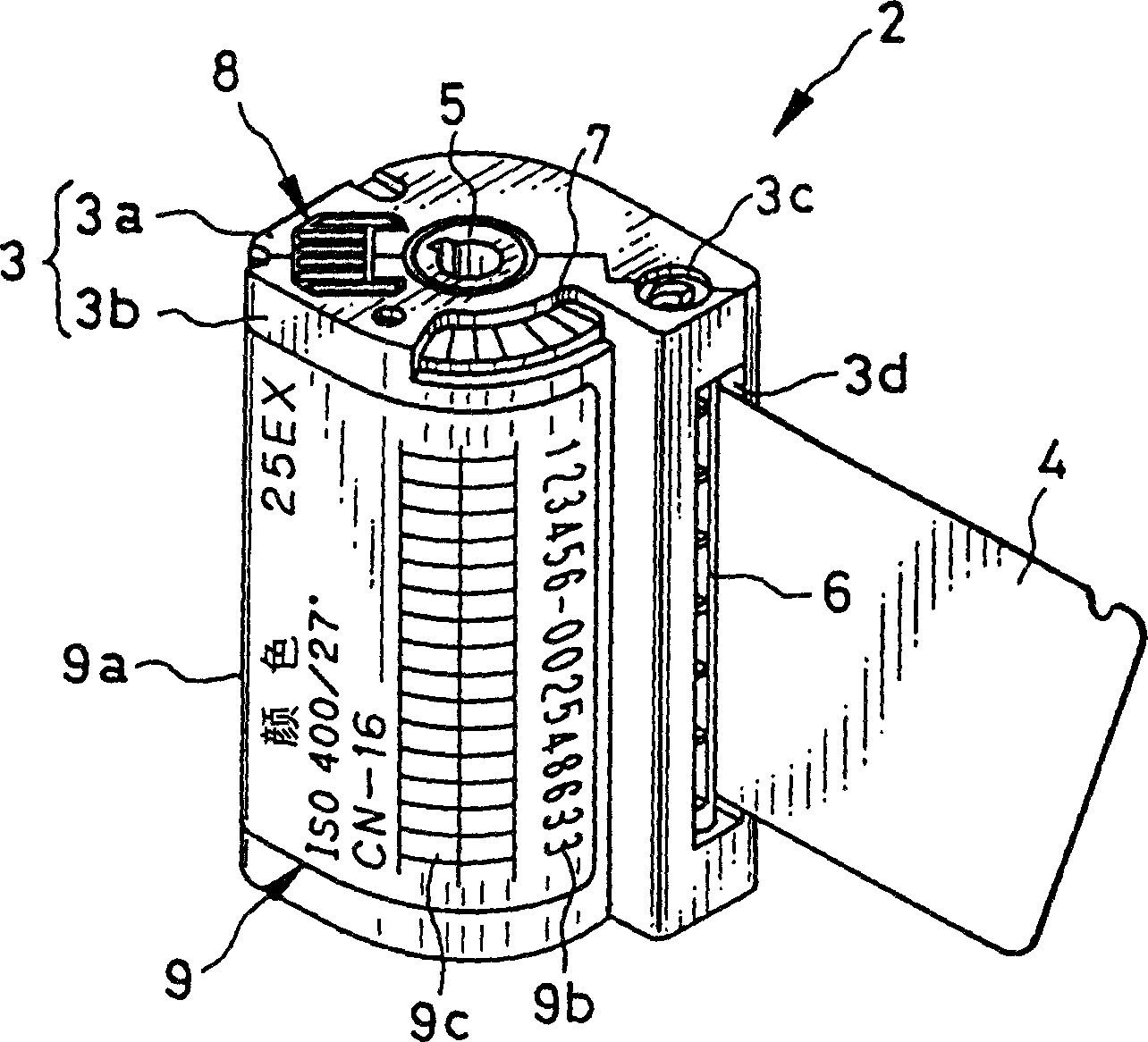

[0041] figure 1 A photo film cassette produced according to the production control method of the present invention is shown. The photo film cassette 2 is composed of a cassette housing 3 and a roll of film 4 contained therein. It generally has the same structure as the type called IX240 except that the photo film cassette 2 is provided with the IC memory 8 . The cassette case 3 is composed of a pair of half cases 3a and 3b made of plastic, and the reel 5 is rotatably mounted between the half cases 3a and 3b. A shutter member 6 is mounted at the film portion 3d of the cassette case 3. As shown in FIG. The light-shielding door member 6 is rotated by a door operating member coupled to the light-shielding door member 6 through the hole 3c of the cartridge case 3 to open and close the film portion 3d.

[0042] The entire length of the film roll 4 is placed inside the cassette housing 3, and the light shielding door member 6 is closed when the photo film cassette 2 is not in use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com