Tire with rounded bead toe and mold for forming the tire

A tire, conical technology, applied in the field of truck and bus tires, heavy-duty tires, can solve the problem of ending the useful life of the carcass, shortening and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

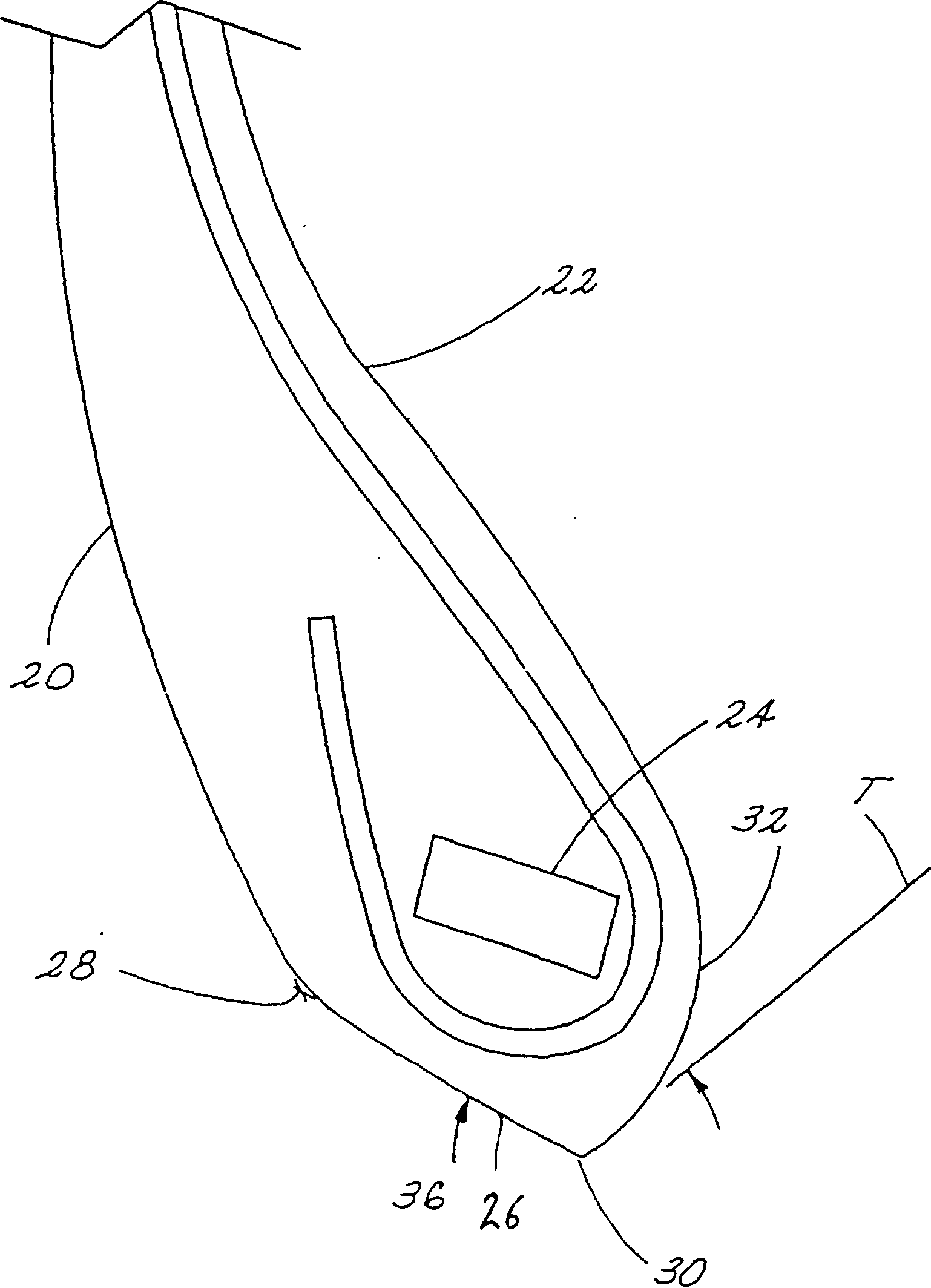

[0018] figure 1 A cross-section of the bead portion of a heavy duty tire, such as a bus or truck tire, is shown. The outer surface 20 and inner surface 22 of the tire provide a reference orientation. The bead portion includes a bead core 24 which in the illustrated embodiment is formed from a coil of rectangular cross-section wire. Other shapes, including oval and circular, can also be used as bead cores, as is well known in the art.

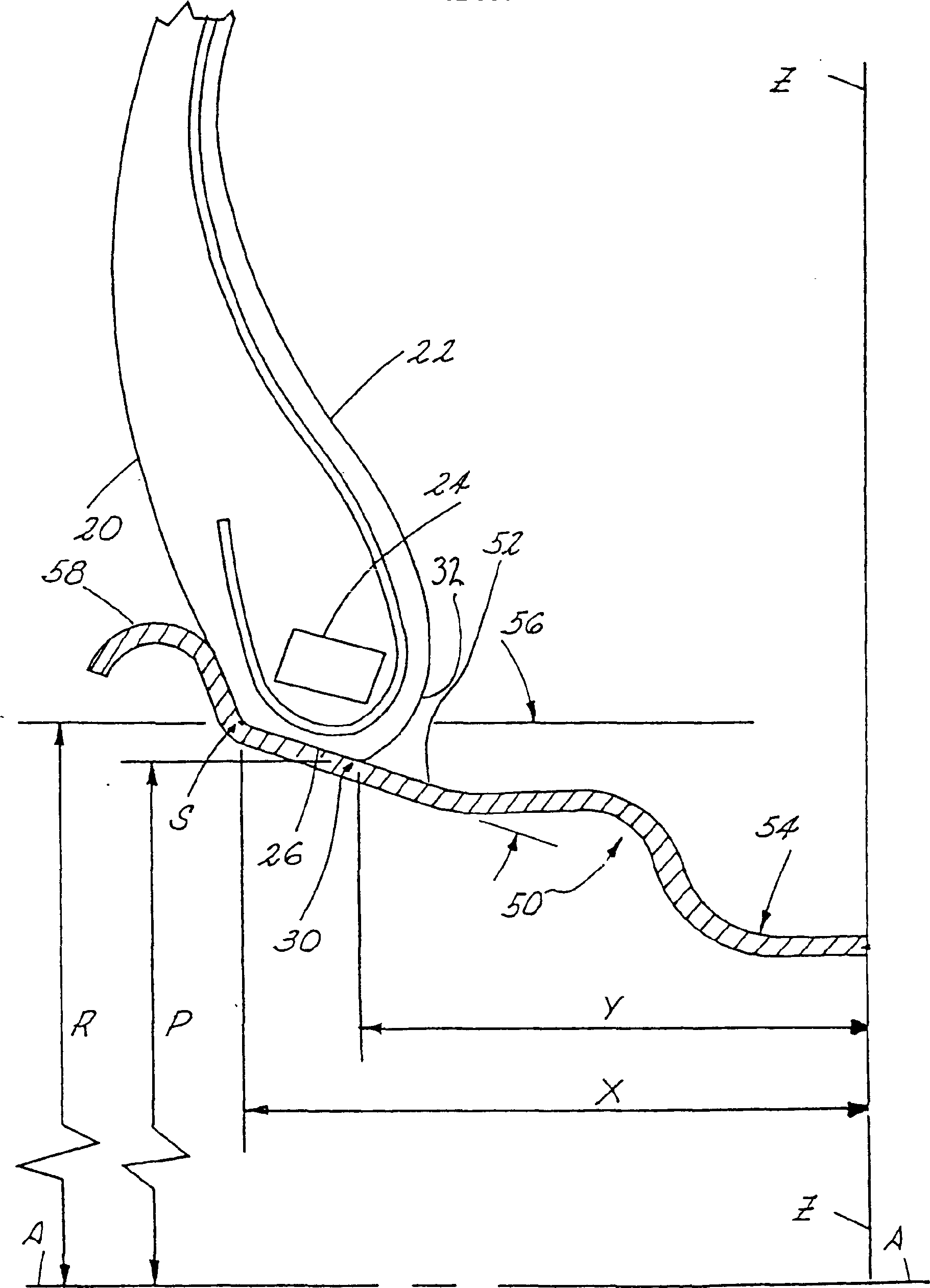

[0019] refer to figure 2 , the bead portion is installed on the rim 50 . The tension on the bead core 24 is transferred to the rim by compressing the rubber between the bead core 24 and the rim seat 52 to secure the bead to the rim, and thus the tire to the rim. The bead portion has a flat-shaped bead seat surface 26 of the rim in combination with a rim seat 52 of the rim 50 . A reference seat point 28 near the outer end of the seat surface 26 coincides with the standard reference point S on the rim. The standard dimensions for rims are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com