Tyre bead with extended mobility

A tire and bead technology, applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of tire installation/removal difficulty, and achieve the effect of easy installation/removal, large degree of freedom, and simplified manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In this specification, the term "cord" generally refers to monofilaments and multifilaments or components, such as multi-strand, plied or any equivalent type of component, regardless of the material and treatment of these cords. They may be surface-treated, coated or pre-finished, for example to aid in bonding with rubber.

[0052] On the other hand, "radial structure" is understood to be arranged at 90°, but according to custom, it can also be an angle close to 90°.

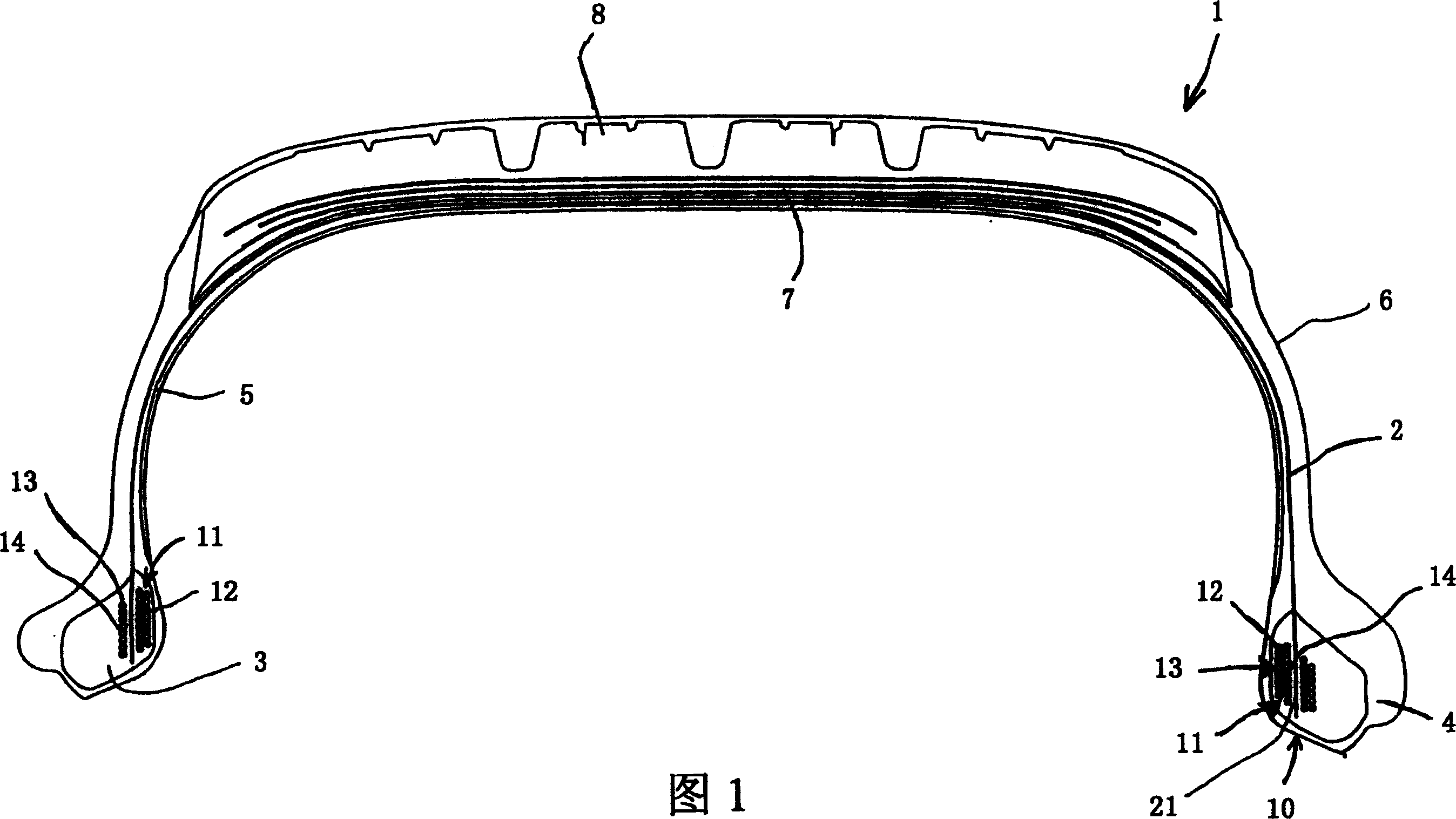

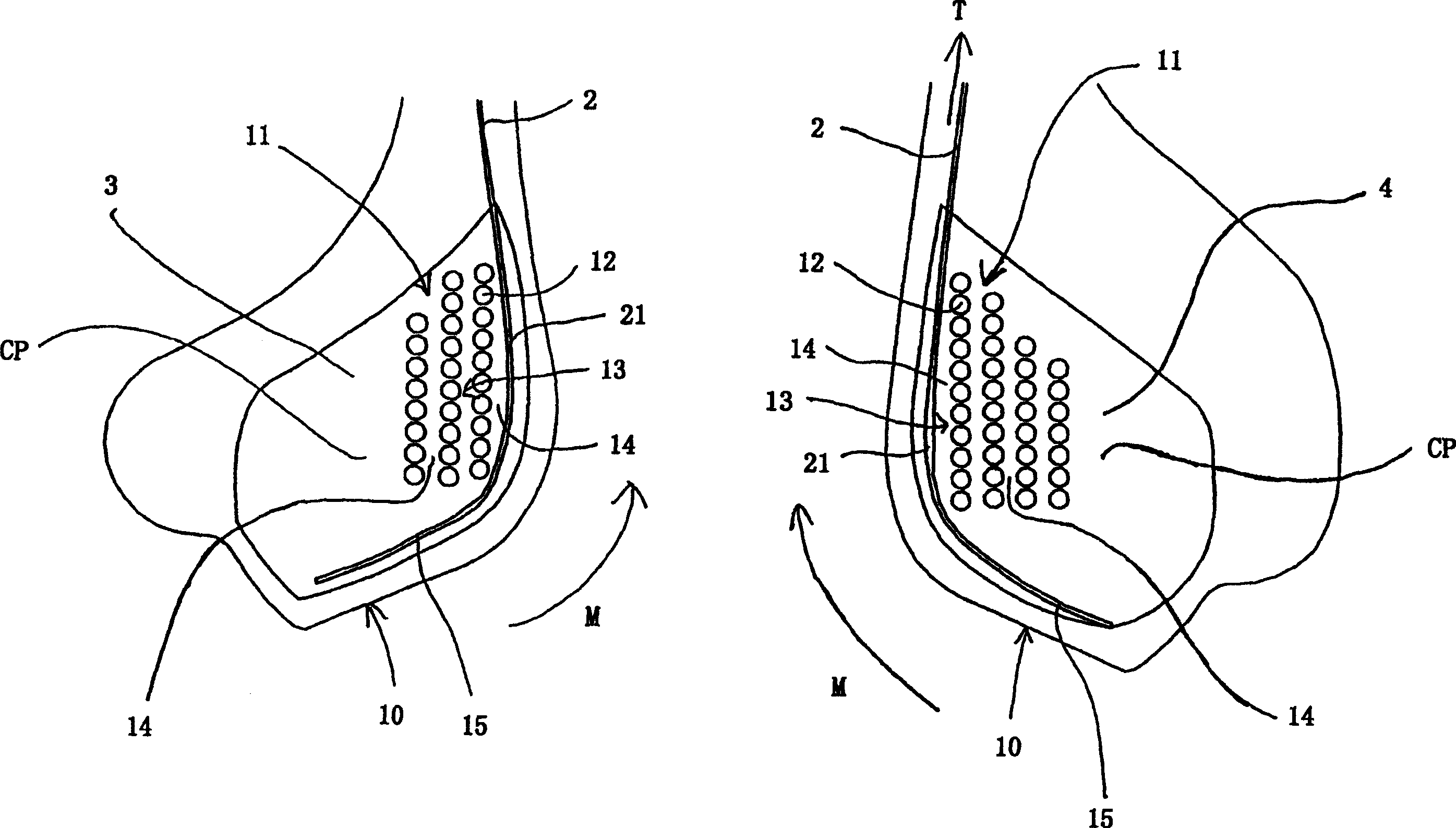

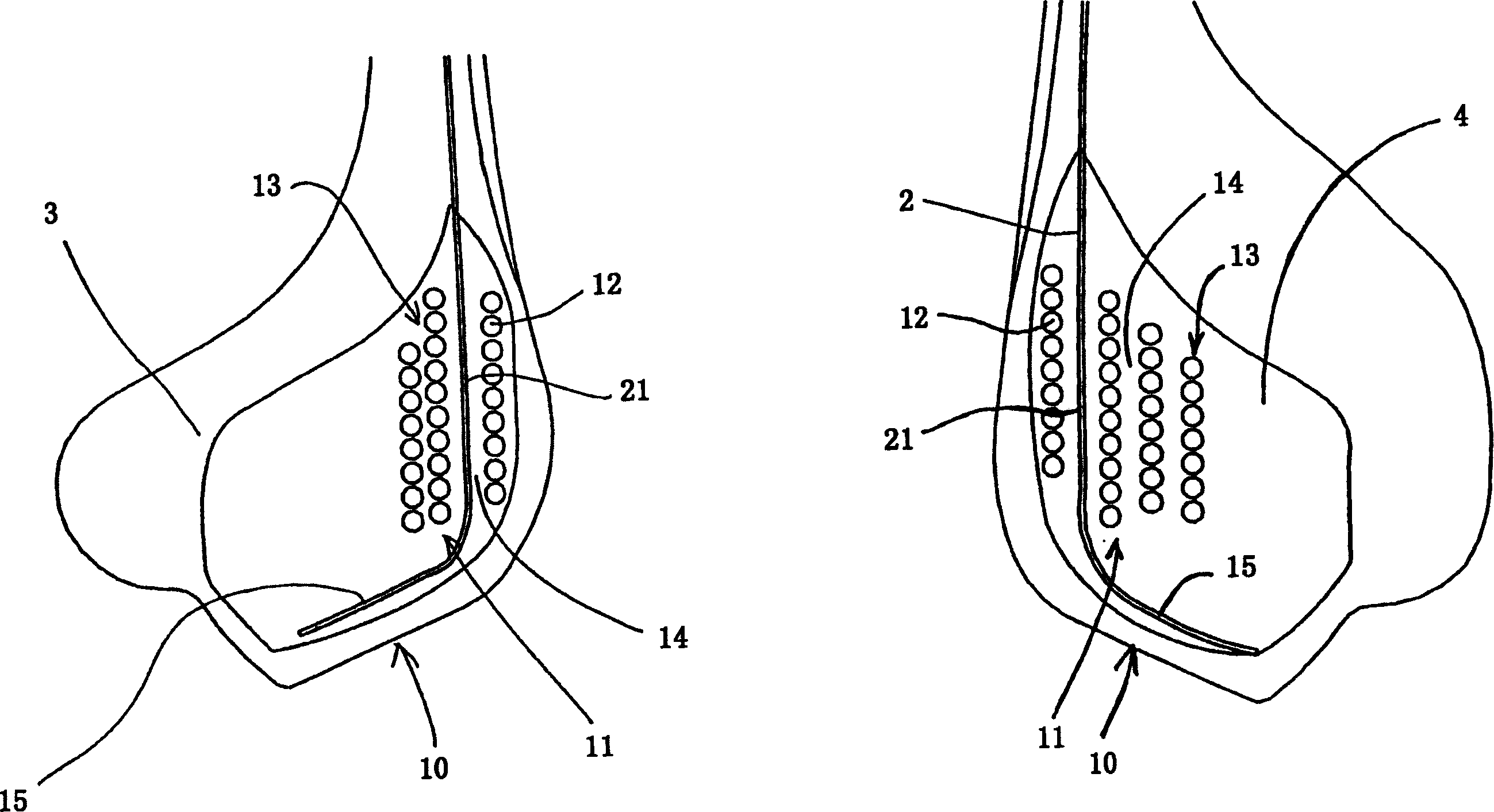

[0053] It is known that generally the carcass ply is turned upside down about the bead wire which then acts to fix the carcass. In particular, therefore, it is subjected to the tensile forces formed on the carcass cords, for example under inflation pressure. The structures described in this document are able to guarantee a similar fixation.

[0054] It is also known to ensure the clamping function of the bead on a rim with bead wires of conventional form. The structure described in this document also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com