Silicone compositions containing acrylate cure accelerator

A curing accelerator, acrylate technology, used in non-polymer organic compound adhesives, adhesives, film/sheet adhesives, etc., can solve the problems of high cost, slow curing rate, insufficient curing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Preparation of the composition

[0058] The following are exemplary methods of preparing the compositions. The silicone-based polymer, crosslinker, catalyst, and optionally release control agent are added together, and the components are mixed together, eg, for about 5 to about 25 minutes or until completely mixed, to prepare a mixture. The acrylate cure accelerator and optionally the O-vinyl ether compound are added to the mixture and further mixed (eg, for about 5 to about 25 minutes) to form a reactive mixture. In one or more embodiments, the step of adding an acrylate cure accelerator and optionally an O-vinyl ether compound to the components of the mixture in the method of making a curable (e.g., thermally curable) composition is at This is done immediately before applying curing conditions, such as heating the composition.

[0059] In one or more embodiments, the silicone-based polymer and crosslinker can be combined together and mixed until a homogeneous blen...

Embodiment

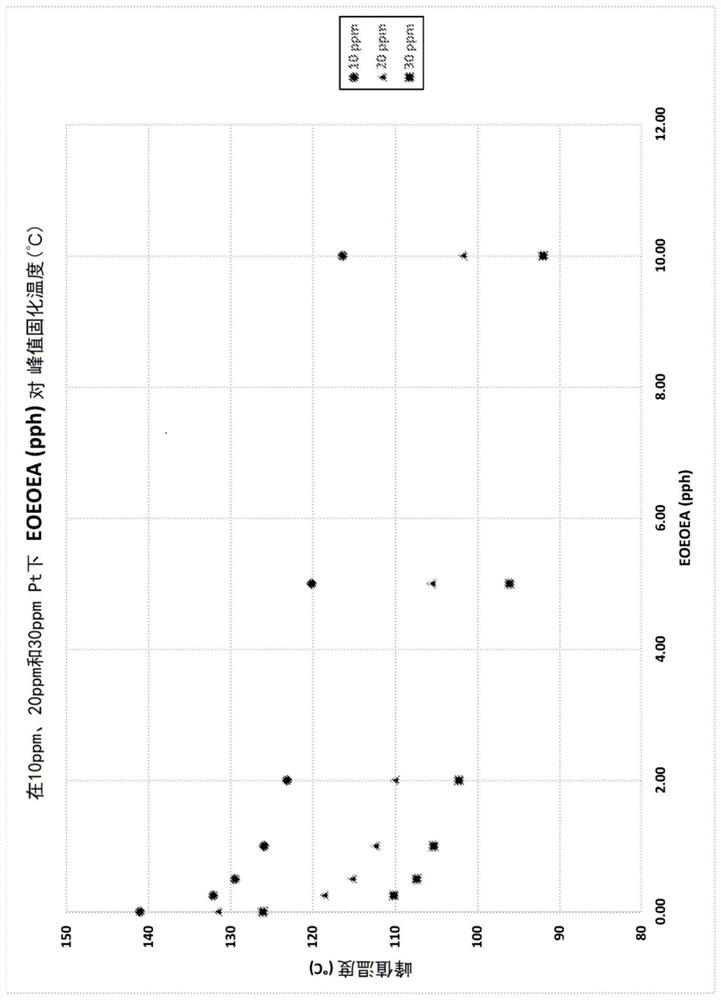

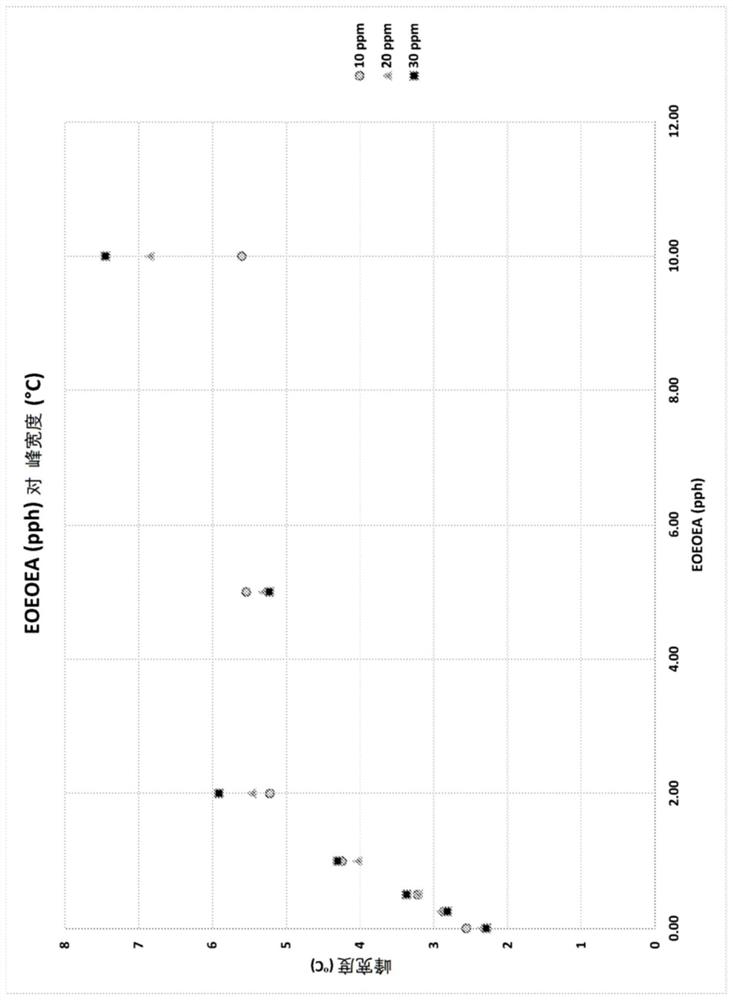

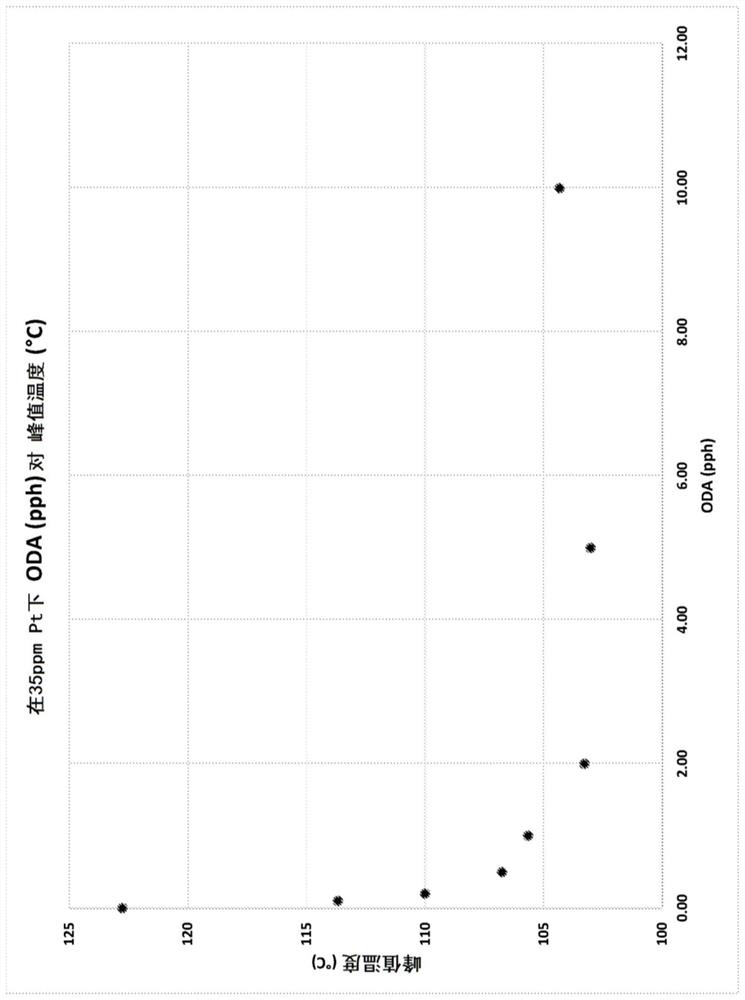

[0080] In order to demonstrate the effect of specific additives on the compositions, cure studies were performed with the compositions prepared according to Table 2.

[0081] Table 2

[0082]

[0083] For the silicone-based polymer, Dehesive 915 (DEH 915), a silicone-based polymer that is a short-chain, linear, bifunctional, vinyl-terminated silicone polymer supplied by Wacker Chemicals, was used. A silicone release modifier resin (eg, release control agent) CRA 17 was added to demonstrate compatibility between the tested additives and the other components in the release coating composition. V90 (silicone crosslinker supplied by Wacker Chemical) and 20 ppm HSPC (20 ppm platinum atomic mass) (platinum catalyst diluted in silicone polymer) were also added to the silicone based composition.

[0084] 1 pph of each additive listed in Table 3 below, including acrylate cure accelerator and O-vinyl compound, was added to the combination mixture identified in Table 2 to form a reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com