Camera and making method thereof

A manufacturing method and camera technology, applied to cameras, instruments, focusing devices, etc., can solve problems such as changes, achieve high-precision focusing, and improve photographic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the drawings.

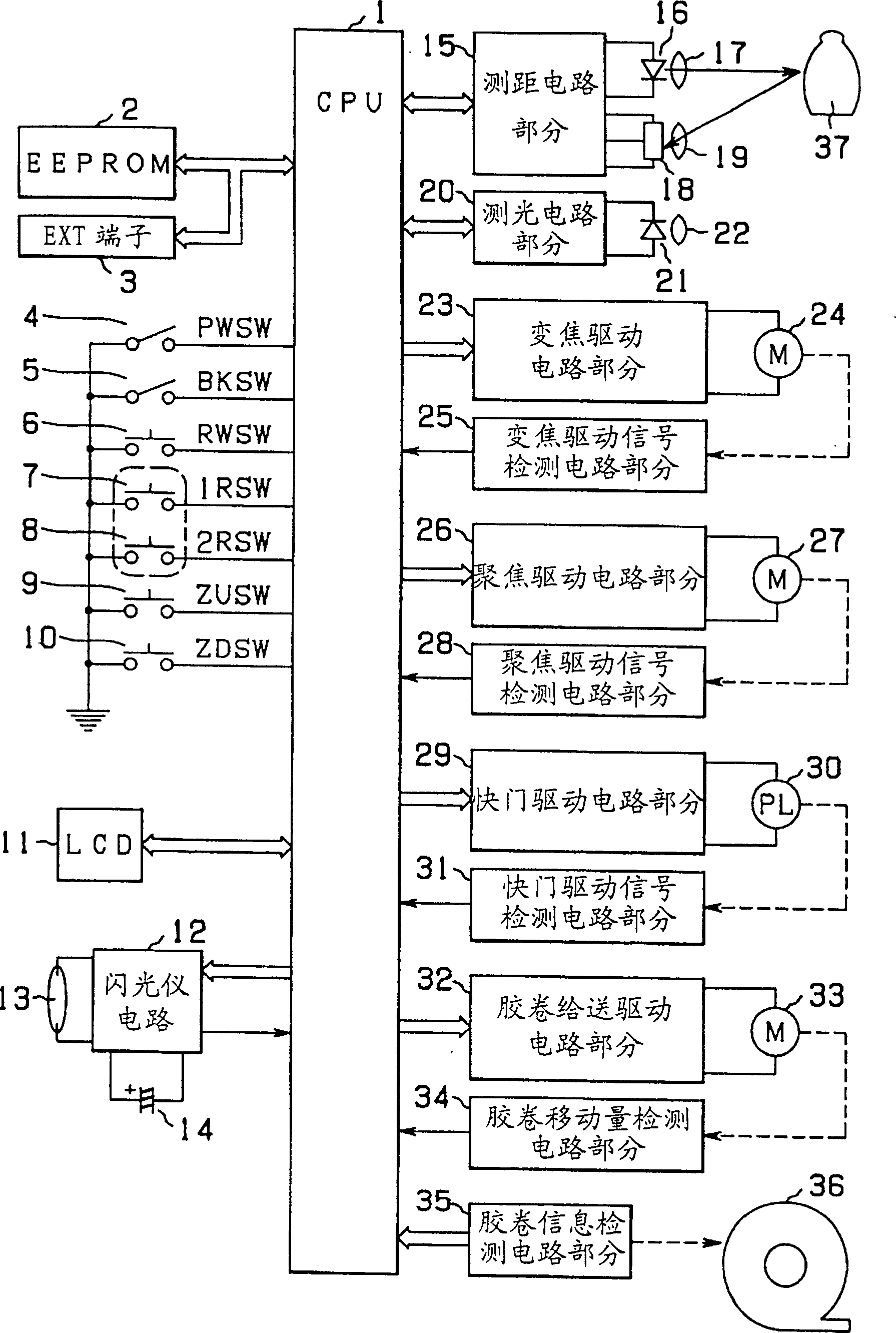

[0028] figure 1 It is a block diagram showing an embodiment of a camera with a zoom lens according to the present invention, and an electrical configuration of the camera.

[0029] like figure 1 As shown, the camera with a zoom lens of this embodiment is provided with a CPU 1 as a control means, and this CPU 1 is a microcomputer for performing various controls on the entire camera system of this embodiment.

[0030] The above CPU1 is respectively connected with: EEPROM2, EXT terminal 3, PWSW4, BKSW5, RWSW6, 1RSW7, 2RSW8, ZUSW9, ZDSW10, LCD11, flash meter circuit part 12, distance measuring circuit part 15, photometry circuit part 20, zoom drive circuit part 23, zoom drive signal detection circuit section 25, focus drive circuit section 26, focus drive signal detection circuit section 28, shutter drive circuit section 29, shutter drive signal detection circuit section 31, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com