Passive magnetic position sensor

A sensor and magnetic permeability technology, which is applied in converting sensor output, using electro/magnetic devices to transmit sensing components, instruments, etc., and can solve the problems of enlarged magnet, unclear output signal of sensor, and unavailability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

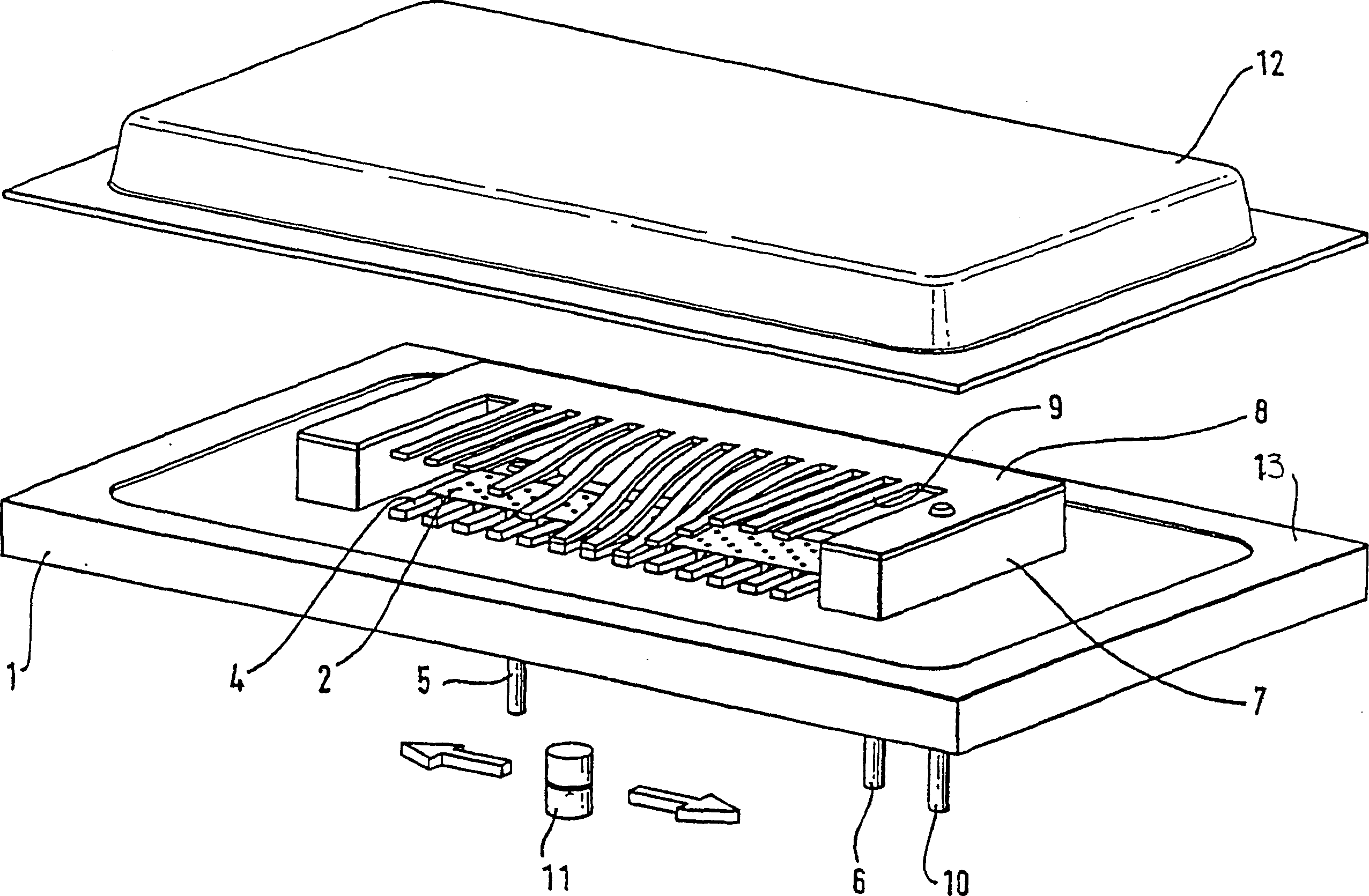

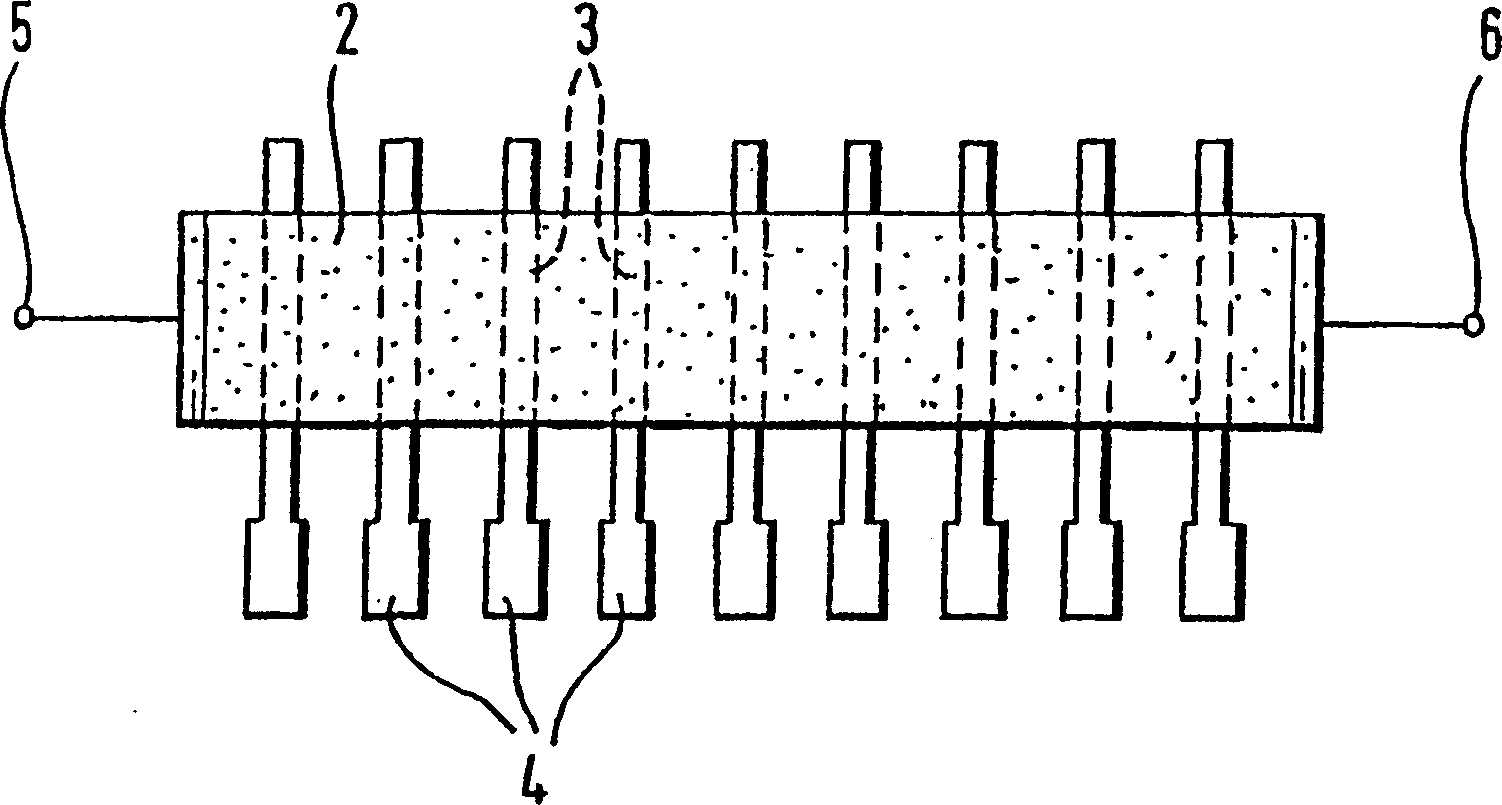

[0018] figure 1 A linear passive magnetic position sensor in the form of a potentiometer in a thick-layer arrangement is schematically shown. On the non-magnetic substrate 1 is a resistive network in the form of a layered resistive track 2 which is arranged between the electrical connection means 5 and 6 .

[0019] as by figure 2 It can be seen that a plurality of printed circuits 3 are arranged parallel to one another on the substrate below the resistive track 2 at a uniform distance. These printed circuits 3 are applied perpendicularly to the resistive lines 2 directly on the substrate 1 . The printed circuit 3 is partly covered by the resistive line 2 . The ends of each printed circuit 3 now form a contact surface 4 which is coated with gold or silver.

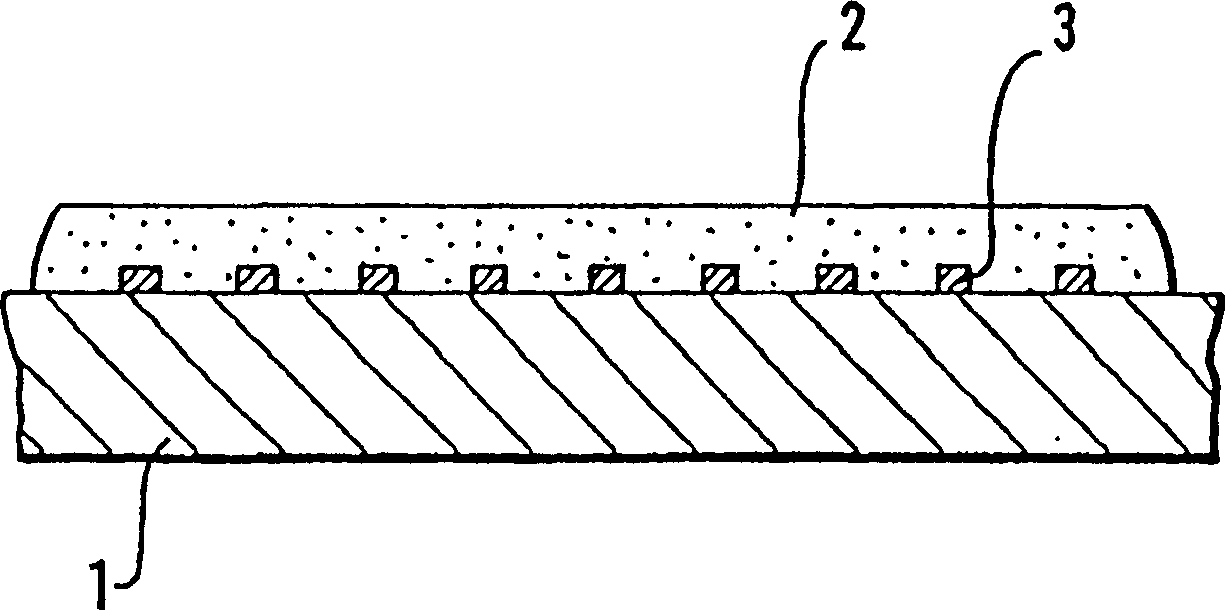

[0020] image 3 The sectional view shows that the printed circuit 3 is completely surrounded by the resistance line 2 in the area of the resistance line 2 in order to ensure a reliable electrical connection. accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com