CD recorder and CD record medium

A disc recording and optical disc technology, which is applied in optical recording heads, optical recording systems, optical recording/reproduction, etc., can solve the problem of less parameters, deterioration of optical disc durability, and larger sum of recording power and erasing power And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

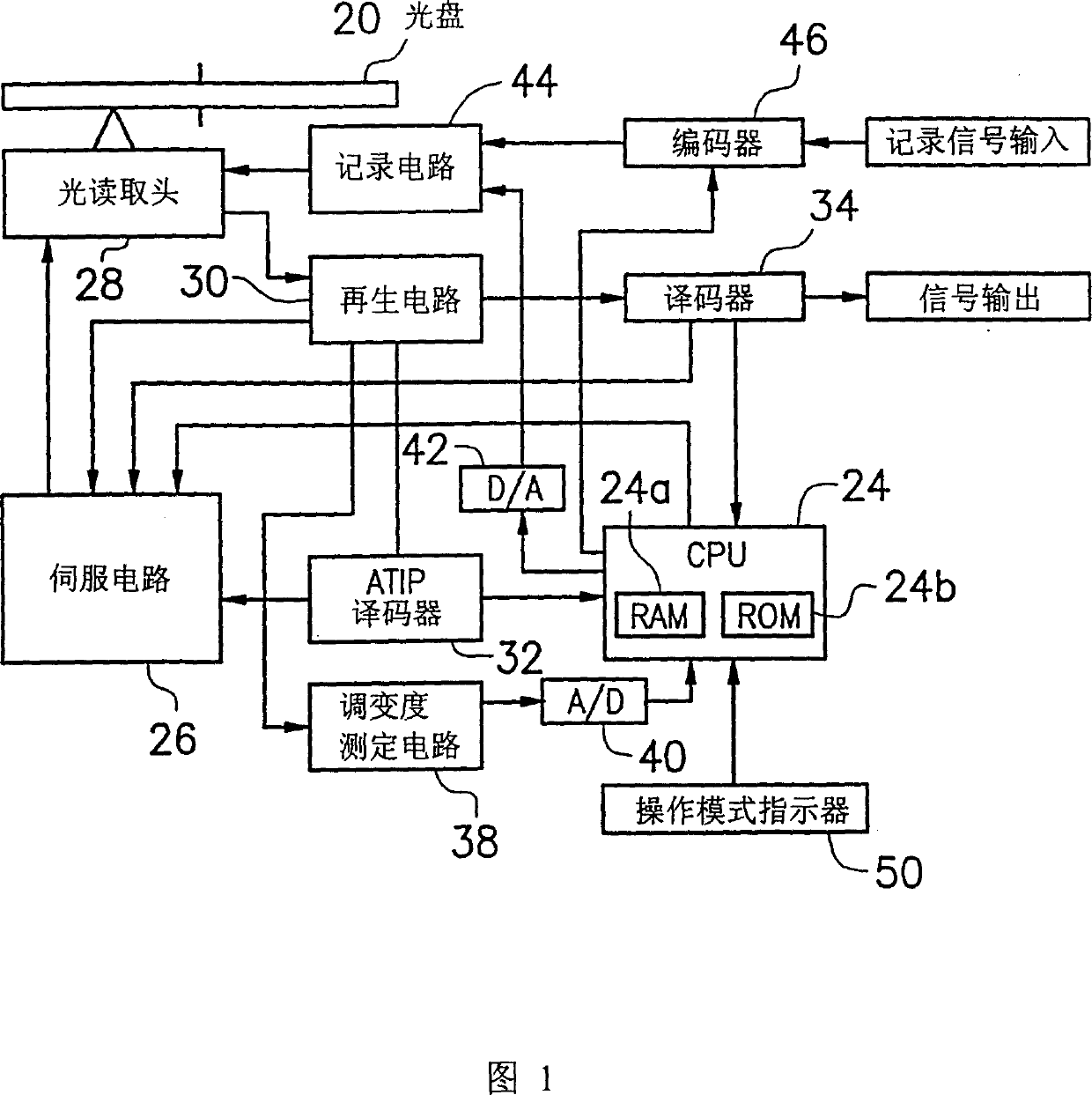

[0041] FIG. 1 is a schematic block diagram of an embodiment of an optical disc recording device of the present invention. As shown in the figure, the optical disc 20 rotates around a shaft 22 driven by a spindle motor. The CPU 24 provides commands to the servo circuit 26 according to the write / read commands provided by the host device.

[0042] The servo circuit 26 is to carry out the above-mentioned constant linear velocity (constant linear velocity, CLV) servo control of the spindle motor, and carry out the rotation control of the sled motor (sled motor) of the optical pick-up head 28, so that the optical pick-up head 28 moves to the optical disc. 20, and perform focus servo and tracking servo control of the optical pickup head 28.

[0043] The laser beam irradiated by the optical pick-up head 28 will be reflected by the recording surface of the optical disc 20, and the reflected light will be detected by the optical pick-up head. The reproduced RF signal obtained at the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com