Method and device for calibrating humidity sensor and sensor arrangement comprising humidity sensor that can be calibrated

A technology of humidity sensor and calibration method, which is applied in the direction of humidity indication, measuring device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

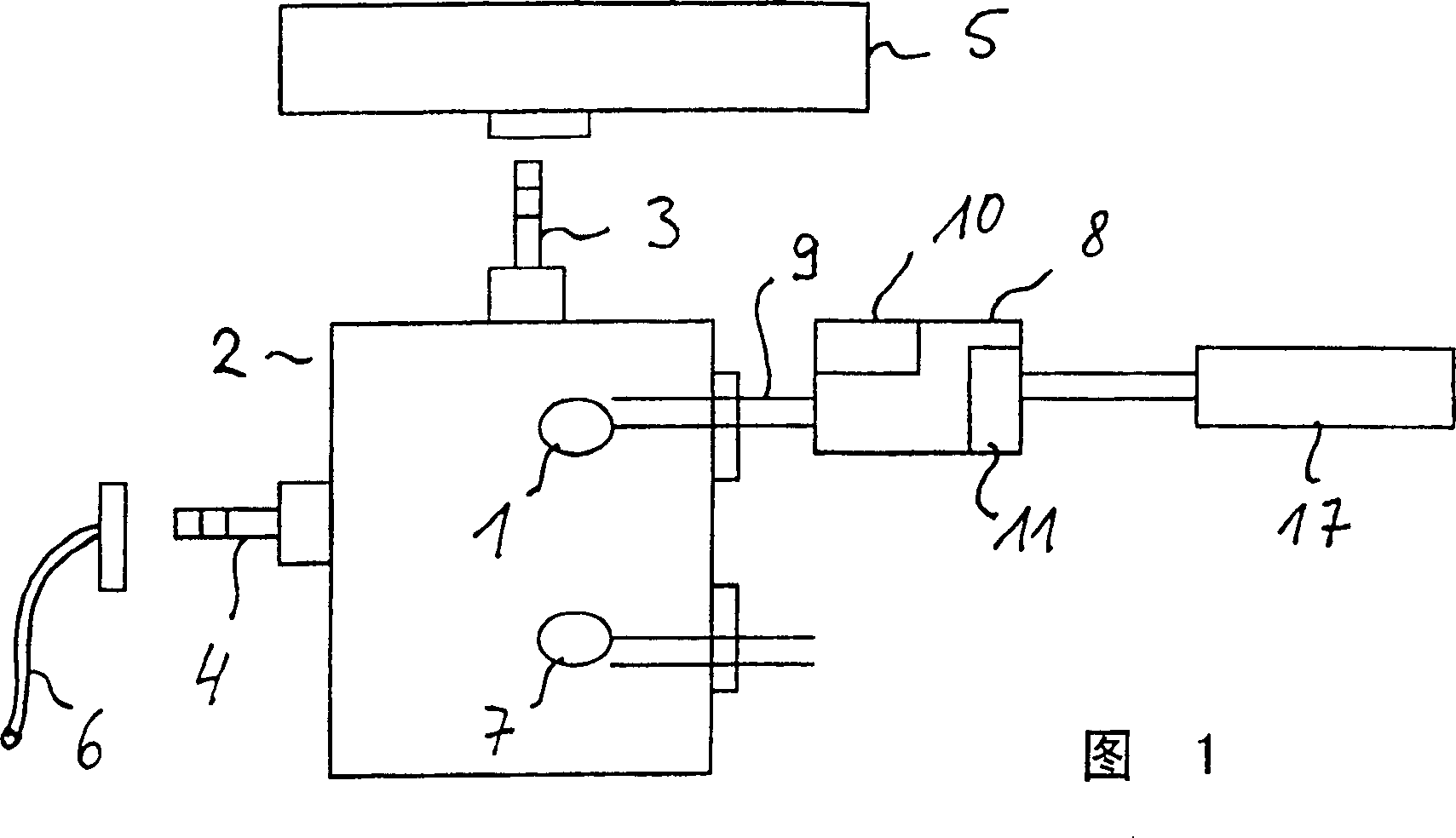

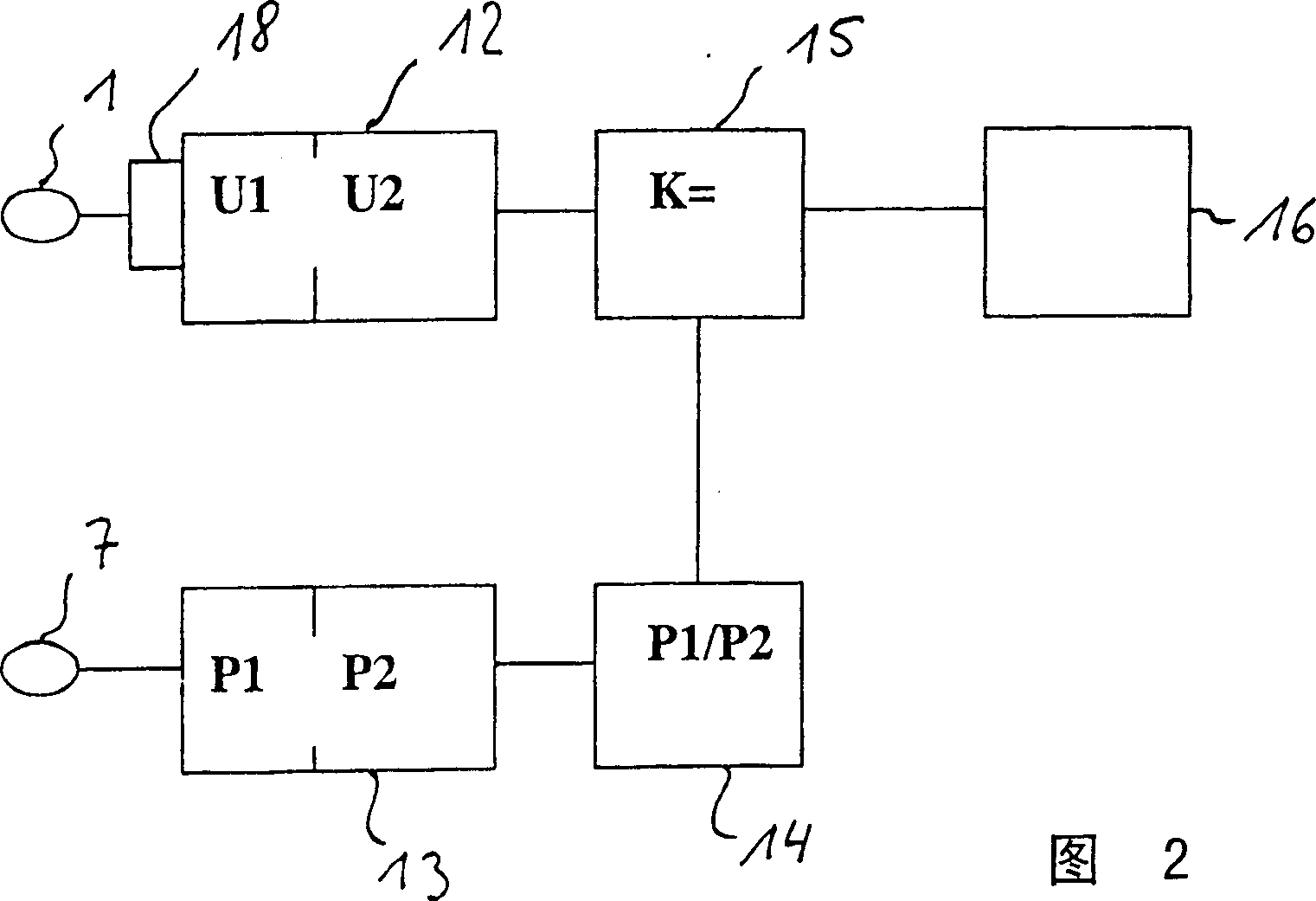

[0031] FIG. 1 shows a humidity sensor 1 in a gas-tight measuring chamber 2 . The measuring chamber 2 has a first gas connection 3 and a second gas connection 4, with which the measuring chamber can be connected on the one hand to a sufficient pressurizable device 5 and on the other hand to a pressure The hose 6 communicates with another air chamber.

[0032] Furthermore, a pressure sensor 7 is arranged in the measuring chamber 2 . The pressure sensor can be a commercially available pressure sensor, but it should be calibrated and have the highest possible measurement accuracy.

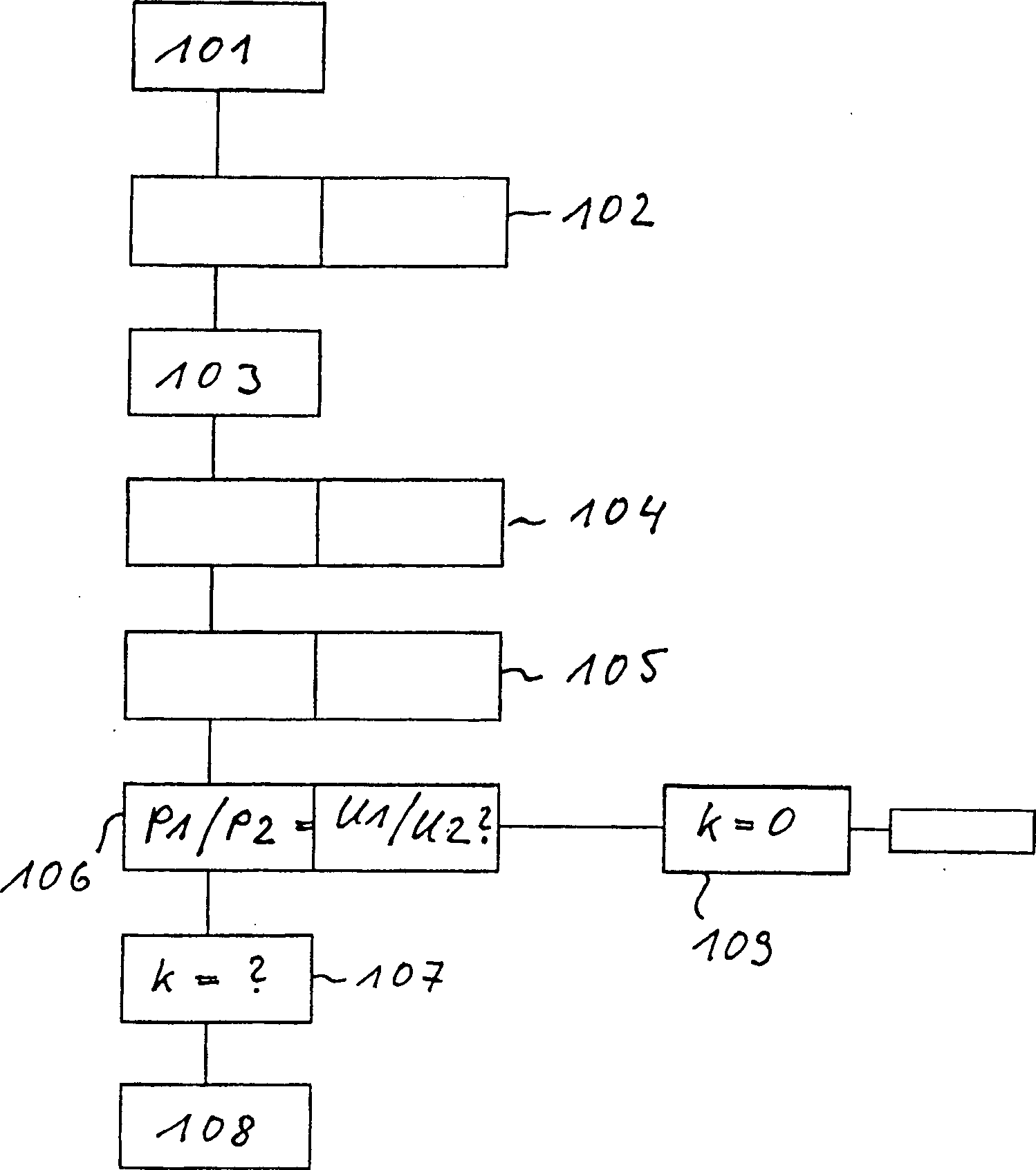

[0033] In order to measure, for example, the gas humidity in the pressurizable device 5 and simultaneously calibrate the humidity sensor 1 , the measuring chamber 2 is first connected to the pressurizable device 5 via a first gas connection 3 , so that gas exchange and pressure equalization can take place. The gas pressure in the measuring chamber is then measured with a pressure sensor 7 and the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com