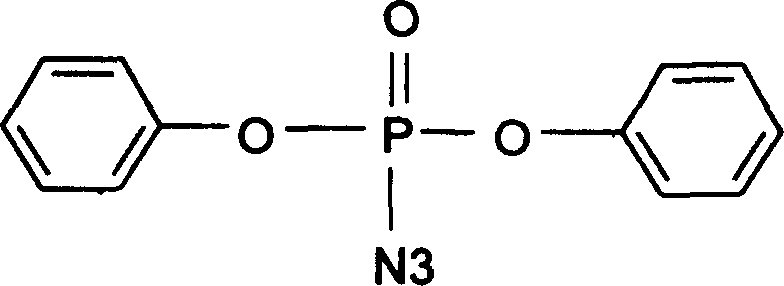

Catalystic preparation of nitrine diphenyl posphate

A technology of diphenyl phosphoric azide and diphenyl chlorophosphoric acid, which is applied in the field of catalytic preparation of diphenyl phosphoric azide by using phase transfer catalysts, can solve the problem of difficult separation of reactants and target products, the yield and purity of target products Low cost, long preparation reaction time and other problems, to achieve the effect of easy large-scale industrial preparation, short time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

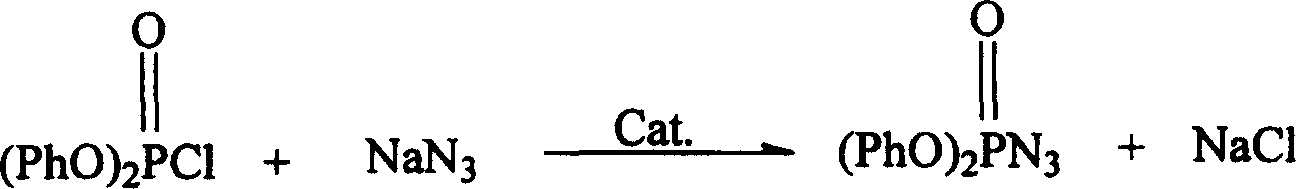

Method used

Image

Examples

Embodiment 1

[0020] Add 47.9g (0.178mol) of diphenyl chlorophosphate, 20.7g (0.32mol) of sodium azide, and 2.5g of tetrabutylammonium bromide into a 100ml three-necked flask and stir vigorously at room temperature for 10 hours. Viscous, then gradually become thinner, the color changes from colorless to light gray, and can be filtered to obtain 42.5g of slightly light yellow or colorless slightly viscous liquid, the yield is 86.2%, and the HPLC content is 99.3%.

[0021] Analysis data: IR(cm -1 ) 3060 (w, C-H), 2170 (s, -N3), 1590 (m), 1490 (s, C=C), 1270 (m, P=O), 960 (s, P-O-Aryl).

Embodiment 2

[0023] Add 48.1g (0.18mol) of diphenyl chlorophosphate, 27.6g (0.42mol) of sodium azide, and 3.0g of TEBA into a 100ml three-neck flask, stir vigorously at room temperature for 15 hours, and filter to obtain 41.8g of slightly light yellow liquid , HPLC content 97.7%, yield 85.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com