Motor for vacuum cleaner

A technology for vacuum cleaners and motor casings, applied to electrical components, electromechanical devices, etc., can solve problems such as poor contact, deformation of brush terminals 32, failure to start the motor, etc., and achieve the effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

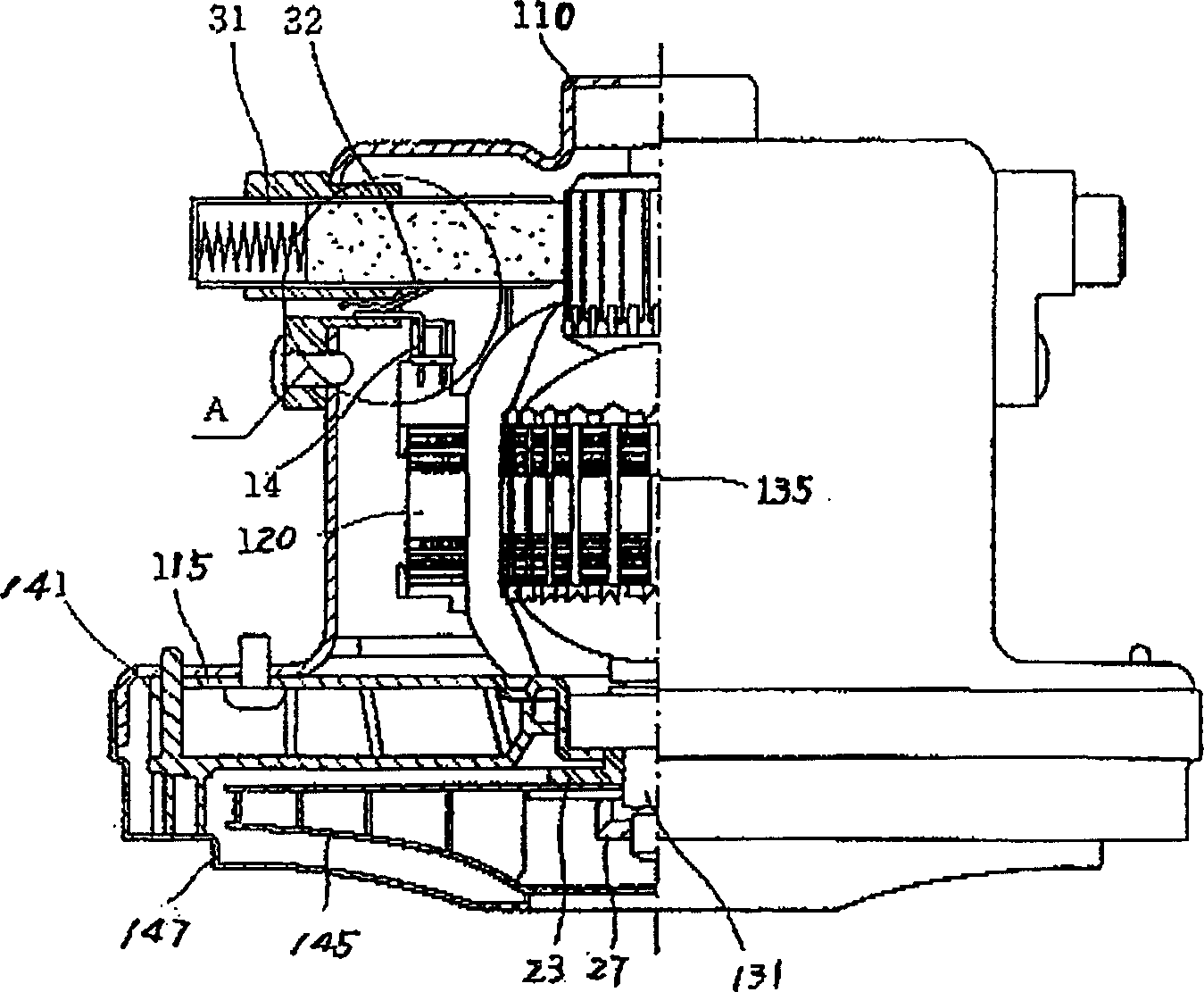

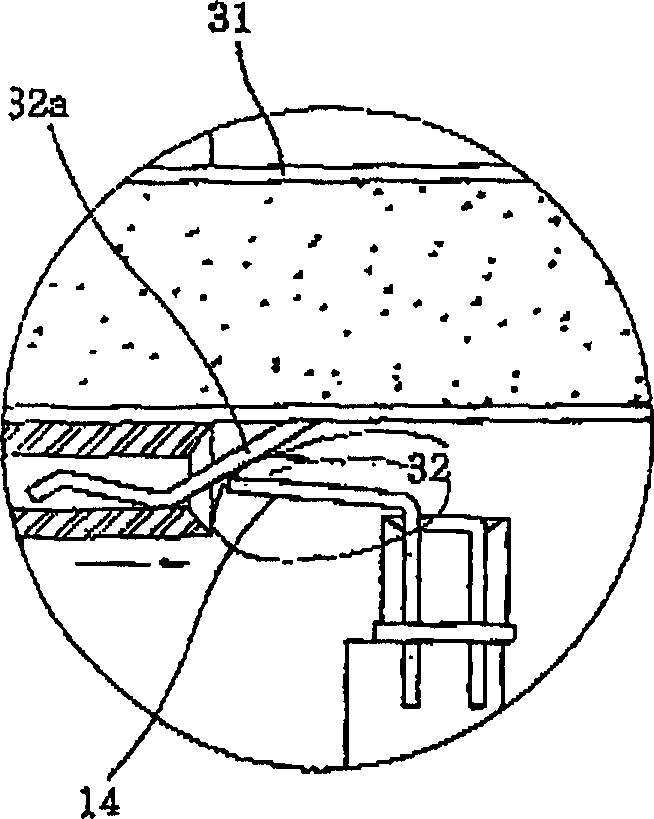

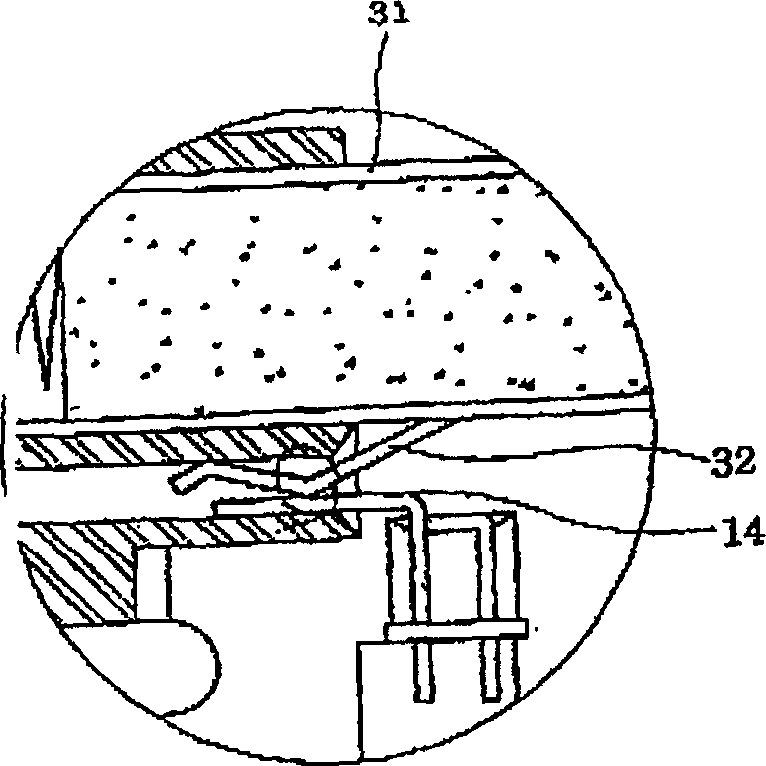

[0026] Referring to the accompanying drawings, a motor for a vacuum cleaner according to an example of the present invention will be described in detail.

[0027] image 3 It is a simple structural diagram of a motor for a vacuum cleaner according to an example of the present invention.

[0028] As shown, the motor 100 has an open motor housing 110 underneath. The stator 120 is pressed and fixed inside the motor housing 110 . Inside the stator 120, there is a rotor 135 pressed into the motor shaft 131 so as to be rotatable. The motor cover 115 covering the lower part of the rotor 135 is integrally connected with the motor casing. Guide vanes 141 are provided on the motor cover 115 . An impeller 145 is fixed to an end portion of the shaft 131 protruding from the outside of the guide vane 141 . An impeller cover 147 surrounding the impeller 145 is fixed on the motor housing 110 . The brush 150 is inserted from the outside to the inside of the motor casing 110 and installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com