Continuous remote transmission float type level gauge

A liquid level gauge and float type technology, applied in the field of liquid level measurement, can solve the problems of difficult assembly and calibration, easy deposition of condensate, and increase the quality of floats, etc., to achieve easy assembly, debugging and calibration, structure and secondary instrumentation Simplicity and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

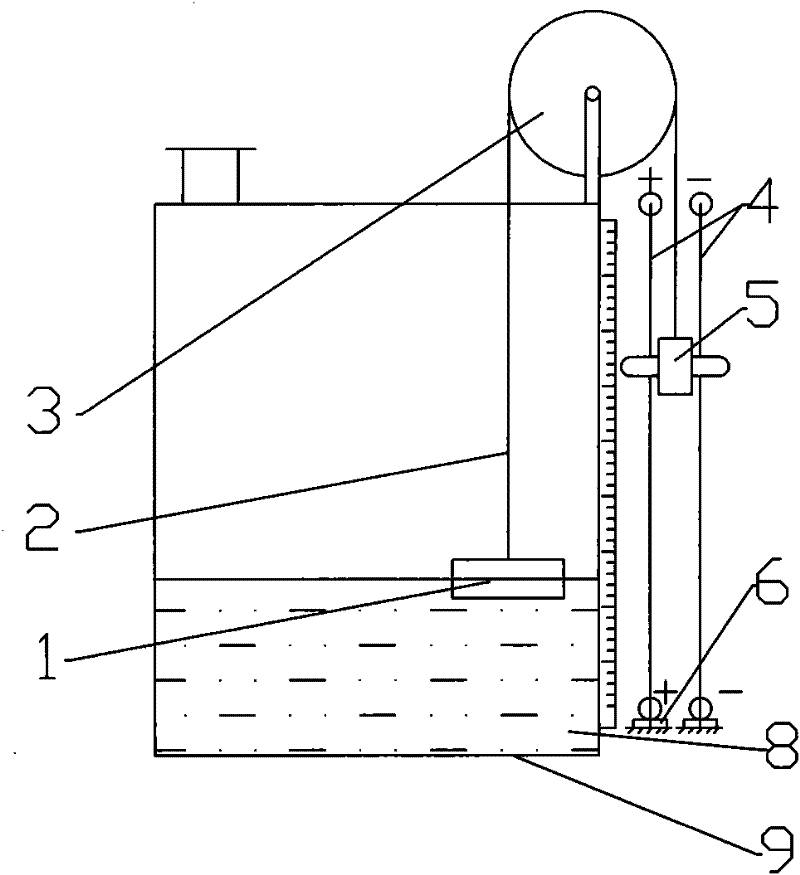

[0099] Embodiment 1: Float type liquid level gauge for atmospheric pressure vessel

[0100] Such as figure 1 , the float type liquid level gauge shown in 2 includes a float 1, a connecting rope or a connecting belt 2 placed on the pulley 3, and its two ends are respectively connected with the float 1 and the magnetic coupling 5, and are fixed perpendicular to the ground on an insulating fixed Two magnetically conductive and electrically conductive guide rails 4 on the block 6, and the pulley 3 are fixed above the container 9.

[0101] The two guide rails 4 are fixed by the insulating block 6 under them, and at least one of them is covered with an insulating layer and wound with a resistance wire;

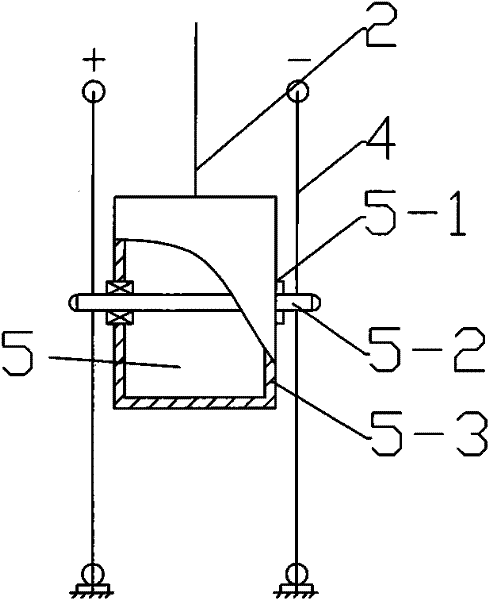

[0102] The magnetic coupling 5 is located between the two guide rails 4, and includes an insulating box 5-3 and a horizontally arranged magnetic shaft 5-2; bearings 5-1 are respectively installed in the holes on the two side plates of the insulating box 5-4; The two ends of the ma...

Embodiment 2

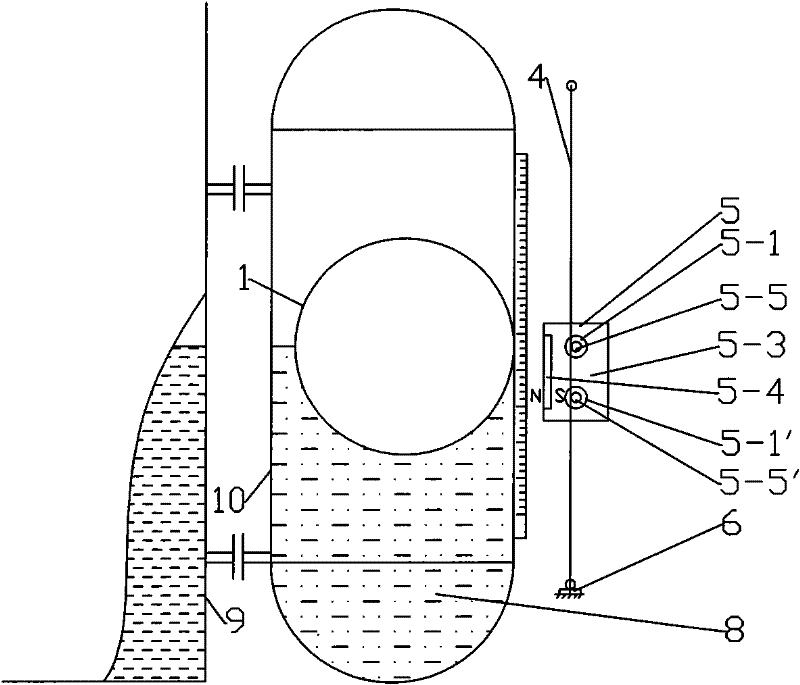

[0107] Embodiment 2: A float type liquid level gauge for a pressure vessel

[0108] Such as image 3 , the float type liquid level gauge shown in 4 comprises a float chamber 10 made of a non-ferromagnetic material that communicates with the measured container 9 and is fixed on the measured container 9, and a float 1 made of a ferromagnetic material in the float chamber 10, It is characterized in that it also includes two guide rails 4 outside the float chamber 10, an insulating block 6 under the guide rails 4 and a magnetic coupling 5, and the magnetic coupling 5 is located between the two guide rails 4, including an insulating box 5-3, The magnetic steel 5-4 and the metal shaft 5-5 arranged horizontally; the magnetic steel 5-4 is located on the side close to the float 1 in the insulating box 5-3, and its magnetic pole is facing the float 1; similar to embodiment 1, the insulation Bearings 5-1 are respectively installed in the holes on the two side plates of the box 5-3; the ...

Embodiment 3

[0116] Example 3: A magnetic float level gauge suitable for pressure vessels with medium temperatures that are not too high

[0117] In the case where the temperature of the medium is not too high, that is, when the magnetic steel will not be demagnetized, in order to increase the magnetic attraction force, a magnetic float type liquid level gauge is used, such as Figure 5 , shown in 6, differs from embodiment 2 in that: its float 1 is made of non-ferromagnetic material, and more than one piece of circular magnetic steel A11 with the same inner diameter as the float is housed in the float, and on the magnetic coupling 5, two guide rails 4 More than 1 circular magnetic steel B5-6 is housed between them, the magnetic steel B5-6 is a circular magnetic steel, and the center of the magnetic steel B5-6 has a hole, which is fixed with the metal shaft by the hole. The magnetic steel B5-6 is fixed in the central part of the insulating box 5-3, the magnetic poles of the magnetic steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com