Pretreatment method for silicon carbide powder sample to be tested by using laser ablation inductively coupled plasma mass spectrometry

A silicon carbide powder and laser ablation technology, applied in the field of analytical chemistry, can solve problems such as poor viscosity, detection of elements affecting the content and distribution, etc., and achieve the effect of good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

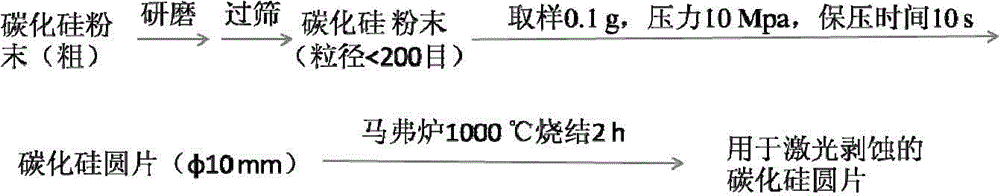

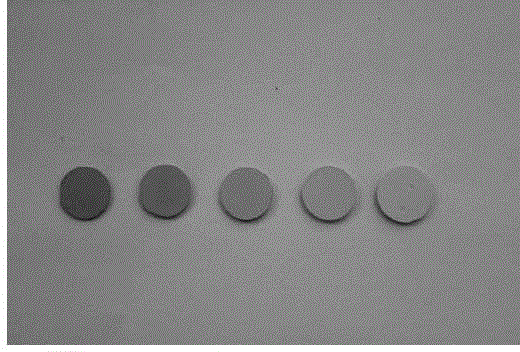

[0037] Weigh 1.0 g of silicon carbide (micron particle size), grind and sieve (200 mesh). Use manual tablet press, holding time 30s, pressure is 10Mpa, it is prepared into of small discs. The prepared silicon carbide wafer was sintered in a muffle furnace at a temperature of 1000°C, and the temperature was programmed to rise from room temperature to 500°C after 1.5 hours; then, the temperature was raised from 500°C to 500°C after 1.5 hours. to 1000°C; keep at 1000°C for 2 hours; then cool down from 1000°C to 500°C in 1.5 hours; finally cool down from 500°C to room temperature in 1.5 hours. After sintering, it was measured by laser ablation inductively coupled plasma mass spectrometry.

Embodiment 2

[0039] Weigh 1.0 g of silicon carbide (nanoscale particle size), grind and sieve (200 mesh). Use manual tablet press, holding time 30s, pressure is 10Mpa, it is prepared into of small discs. The prepared silicon carbide wafer was sintered in a muffle furnace at a temperature of 1000°C, and the temperature was programmed to rise from room temperature to 500°C after 1.5 hours; then, the temperature was raised from 500°C to 500°C after 1.5 hours. to 1000°C; keep at 1000°C for 2 hours; then cool down from 1000°C to 500°C in 1.5 hours; finally cool down from 500°C to room temperature in 1.5 hours. After sintering, it was measured by laser ablation inductively coupled plasma mass spectrometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com