Integrated double end electric arc spraying equipment

A technology of arc spraying equipment and double-head spray gun, which is applied in liquid spraying device, coating, spraying device and other directions, can solve the problems of cumbersome spraying process, waste of resources and energy, low spraying efficiency and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

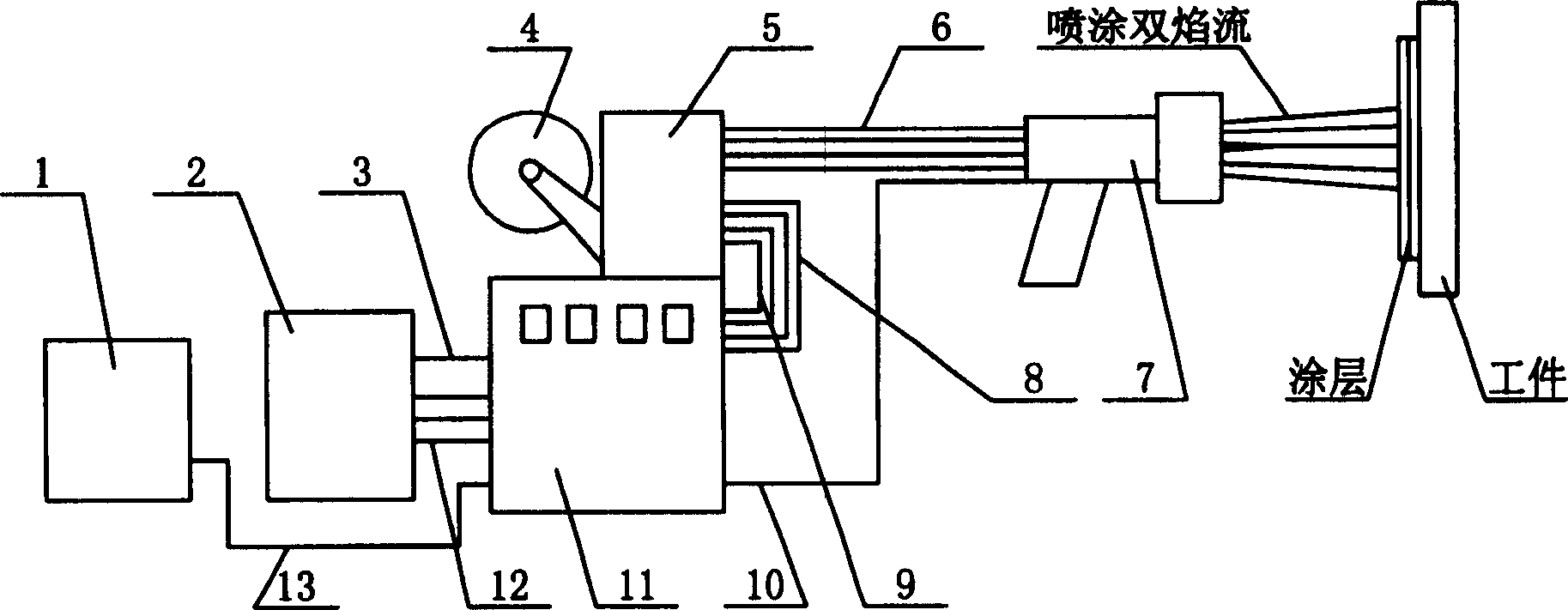

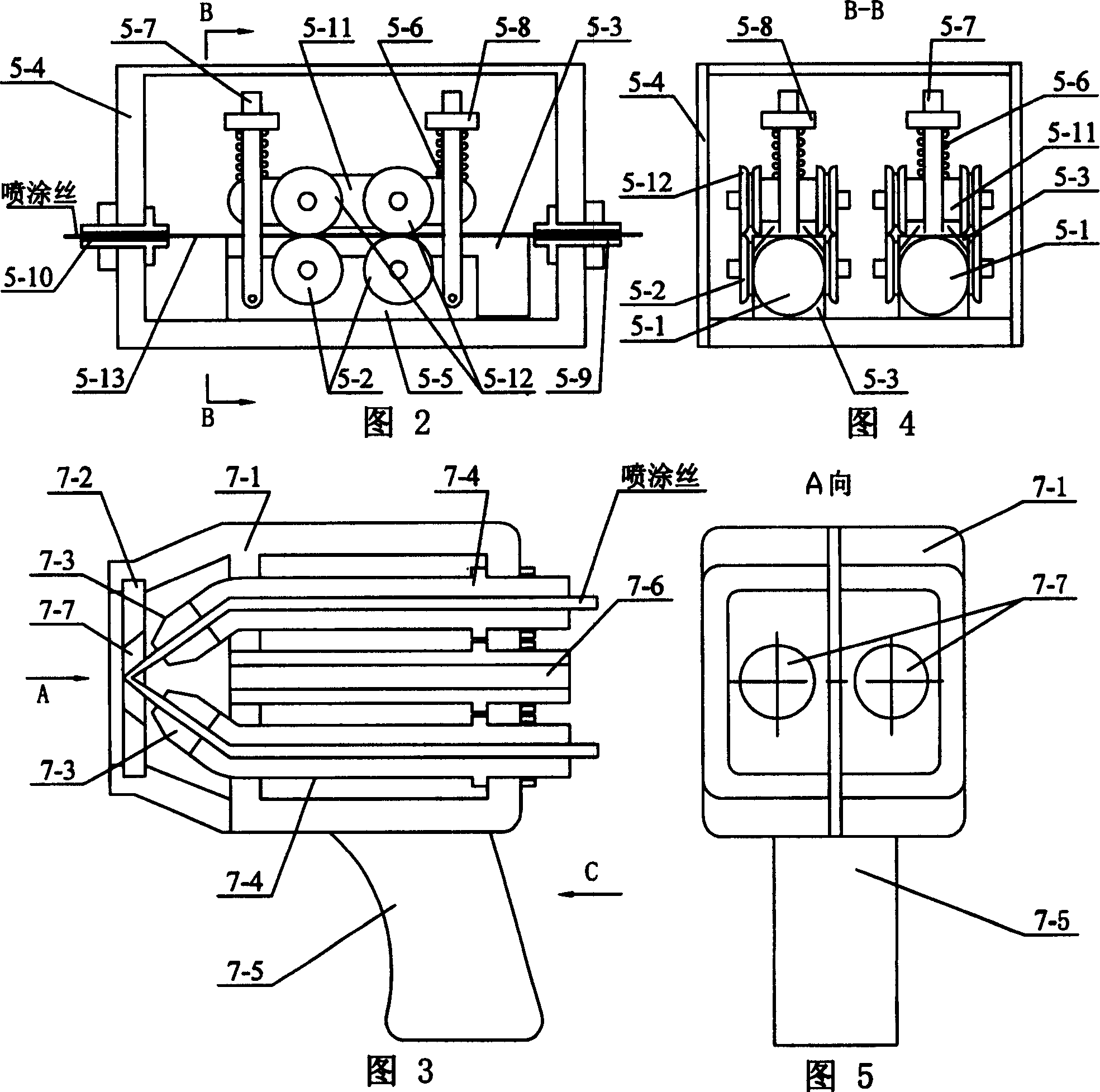

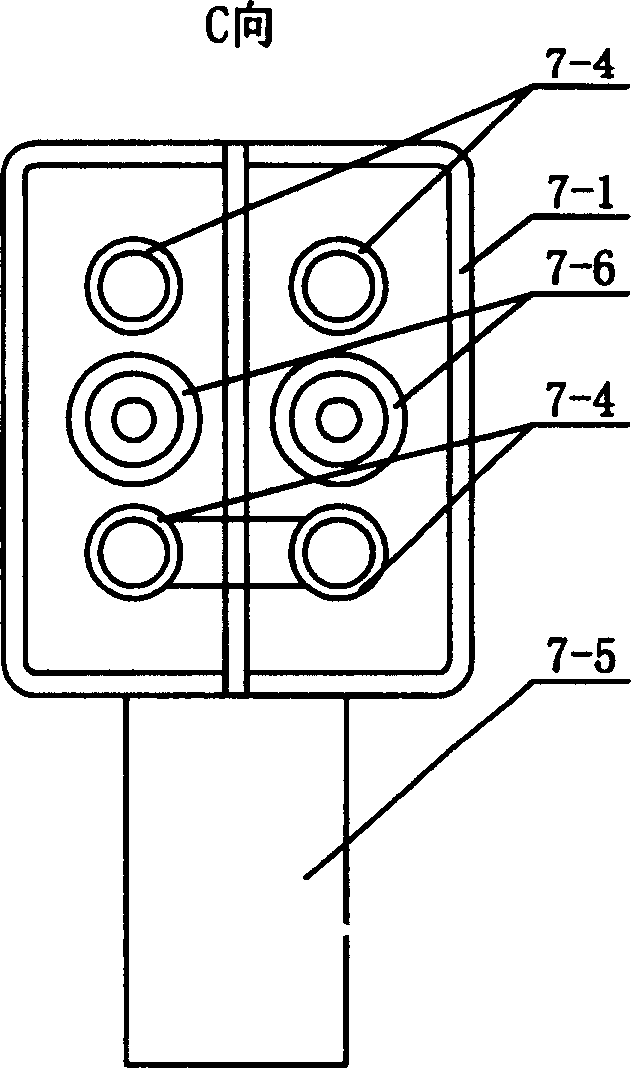

[0005] Specific implementation mode one: (see Figure 1-Figure 6 ) The integrated double-head arc spraying equipment in this embodiment consists of an air compressor 1, a spraying power supply 2, a No. 1 control line 3, a wire feeding reel 4, a wire feeding mechanism 5, a cable and a wire guide tube 6, a double-head spray gun 7, No. 2 output cable 8, No. 2 control line 9, No. 2 air compression pipe 10, control cabinet 11, No. 1 output cable 12, and No. 1 air compression pipe 13; the wire feeding mechanism 5 is fixed on the upper end of the control cabinet 11. The wire reel 4 is set on the wire feeding mechanism 5, the wire feeding mechanism 5 and the control cabinet 11 are connected by the second output cable 8 and the second control line 9, and the spraying power supply 2 and the control cabinet 11 are connected by the first control line 3 is connected with the No. 1 output cable 12, the No. 1 air compression tube 13 is connected between the air compressor 1 and the control c...

specific Embodiment approach 2

[0006] Specific implementation mode 2: This implementation mode is the preparation of anti-fatigue and high wear-resistant spray coating on the surface of a certain part of the power station equipment.

[0007] 1. Conditions: The material of this accessory is a brass component. It is used under the condition of 300 ° C. There is a slight friction and vibration during use. The coating is required to have certain anti-fatigue and anti-wear properties to ensure that the coating cannot There are any defects that affect the performance such as layering and falling blocks. The sprayed part is a rectangular plane, the coating area is 50mm wide and 100mm long, and the total thickness of the coating after grinding is 2mm.

[0008] 2. Coating design: According to the service conditions of the accessories, the size and shape of the coating and the quality requirements of the coating, a multi-layer bimetallic coating structure with a soft layer sandwiching a hard layer is selected. Consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com