Electric punching device

A hole puncher, electric technology, applied in metal processing and other directions, can solve the problems of large size, difficult to carry, a large number of disassembly, etc., to achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

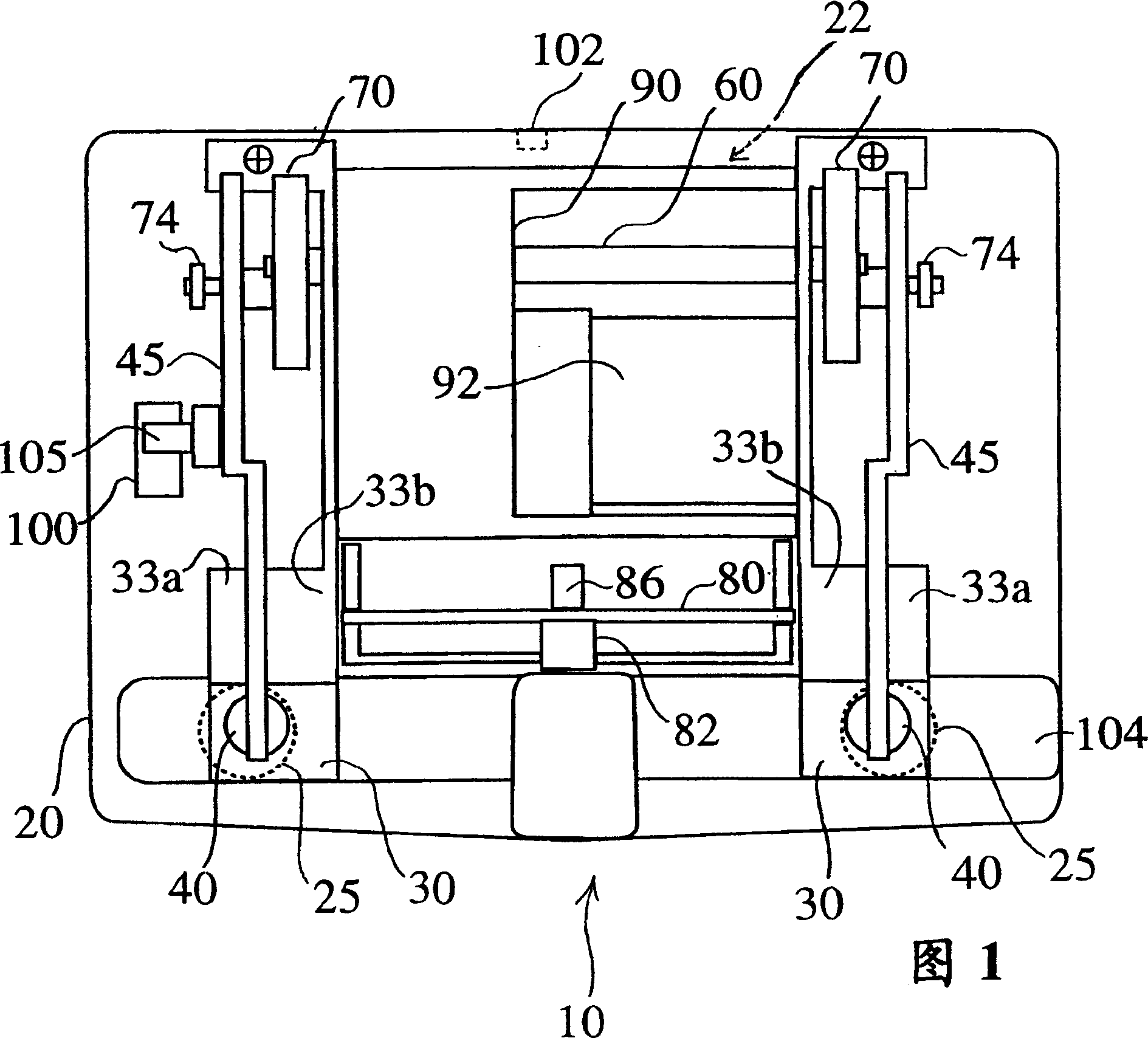

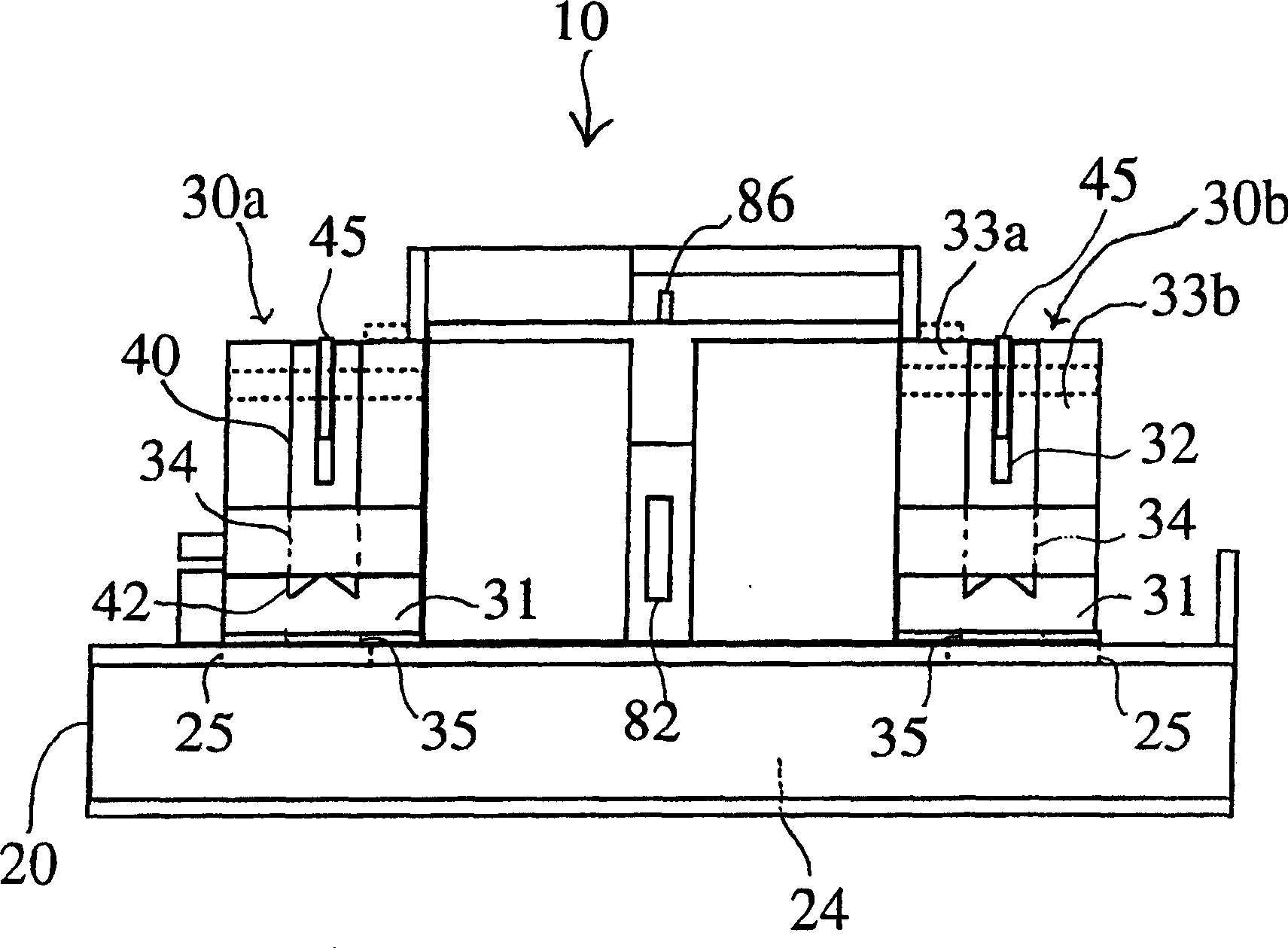

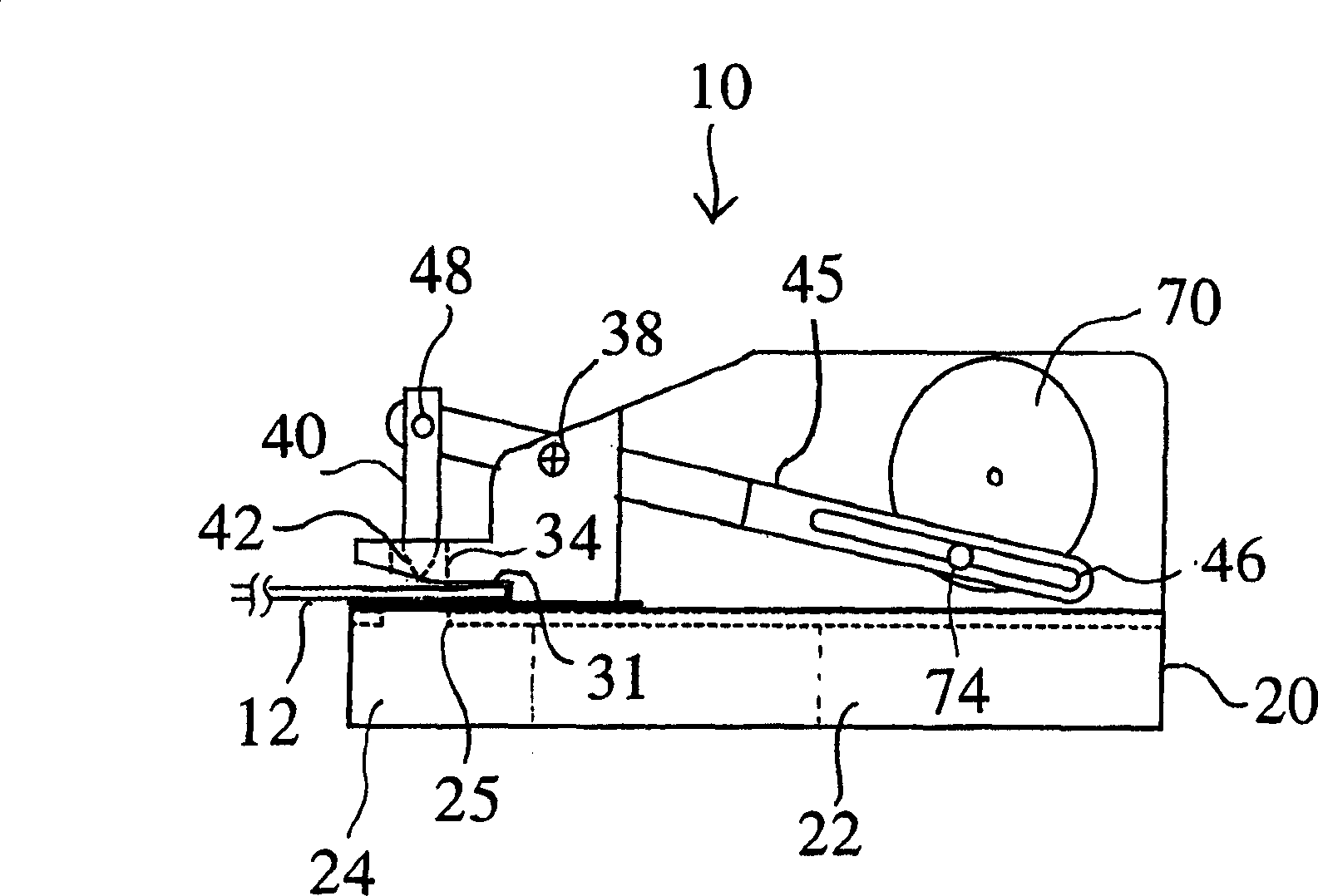

[0021] An embodiment of the electric hole puncher of the present invention will now be described with reference to the accompanying drawings. Figures 1, 2 and 3 are the plan view, front view and side view of the electric puncher with the hole pitch set at 70 mm, respectively. Fig. 4 is a plan view of an electric puncher with a pitch of 80 mm.

[0022] Figure 1 and figure 2 As shown, the electric hole puncher 10 according to the present invention includes a main frame 20 , a supporting member 30 , a punching member 40 and a driving part 90 .

[0023] The main frame 20 is composed of a battery case 22 , a paper waste collection tank 24 and a drive section 90 including a motor 92 . The battery box 22 is a shell for loading one or more batteries as a power source, and also has an openable box cover.

[0024] The paper dust collection tank 24 is a housing for collecting paper dust generated when documents and the like are punched, that is, paper dust from a stack of paper 12 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com